Contact system with heat dissipation unit

A technology of heat dissipation unit and contact system, which is applied to electrical components, circuit breaker contacts, parts of protection switches, etc., can solve the problems of small thermal load capacity of the contact system, and improve the possibility of optimizing the internal space, The effect of improving work performance and improving heat load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

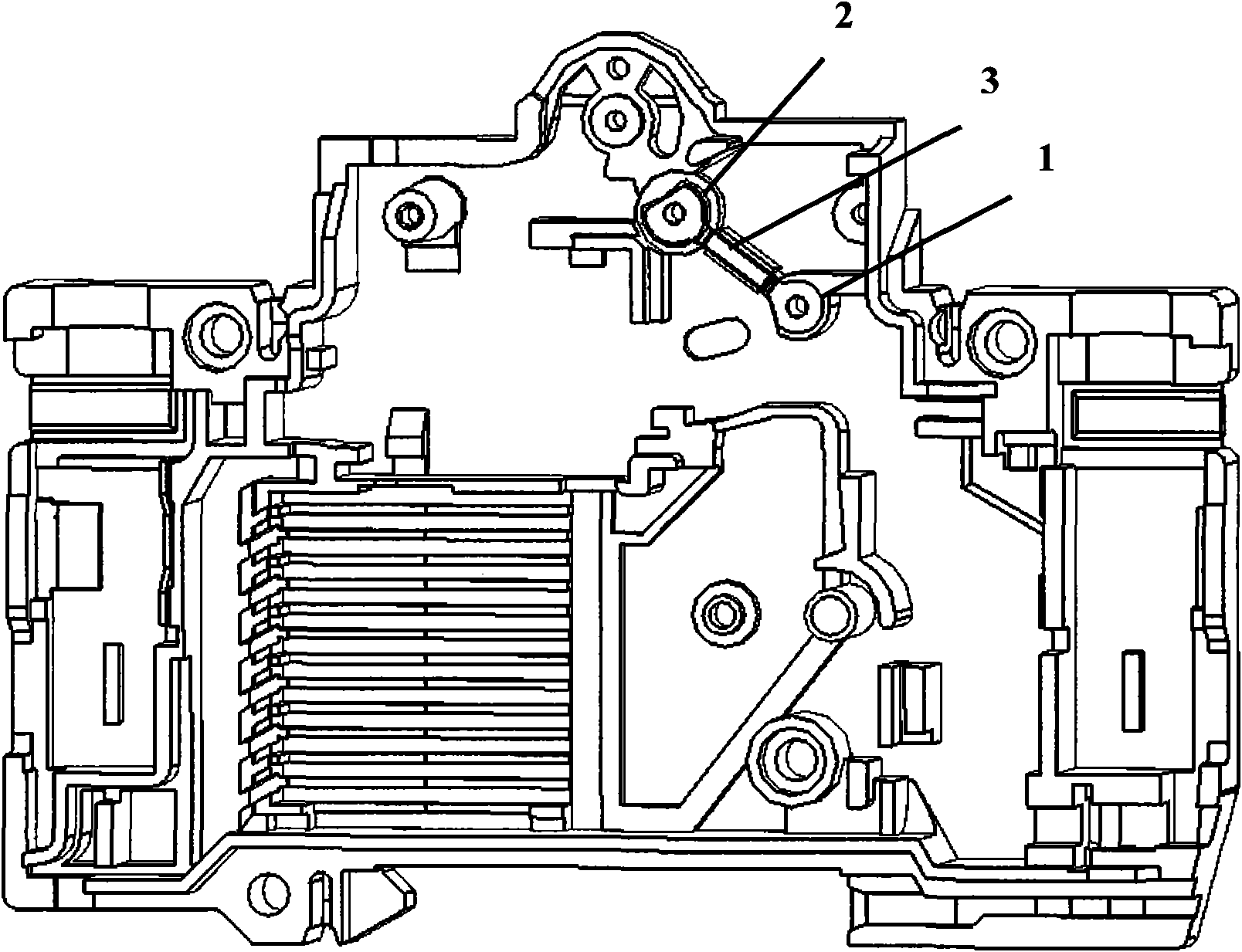

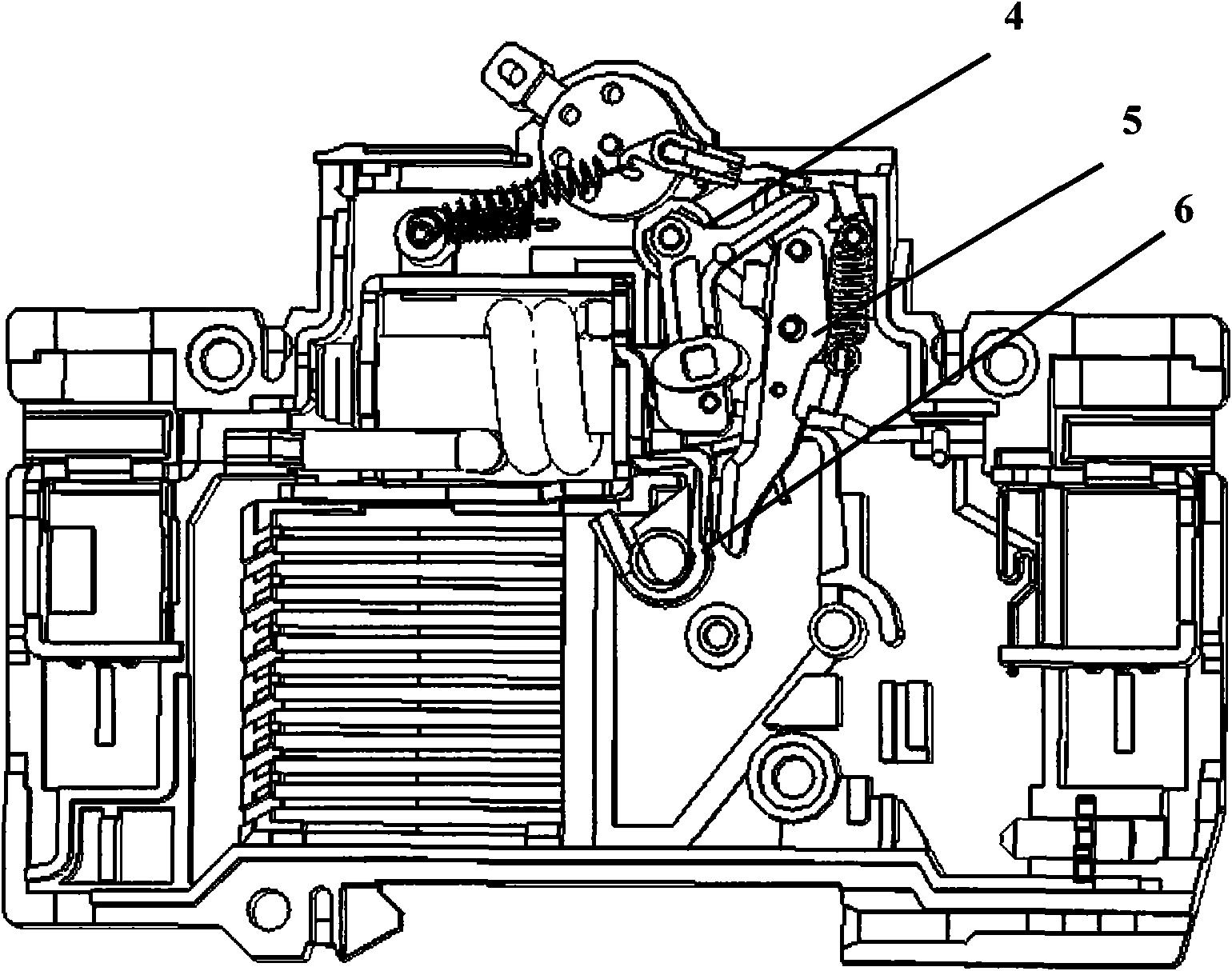

[0016] Further description will be made below in conjunction with the accompanying drawings.

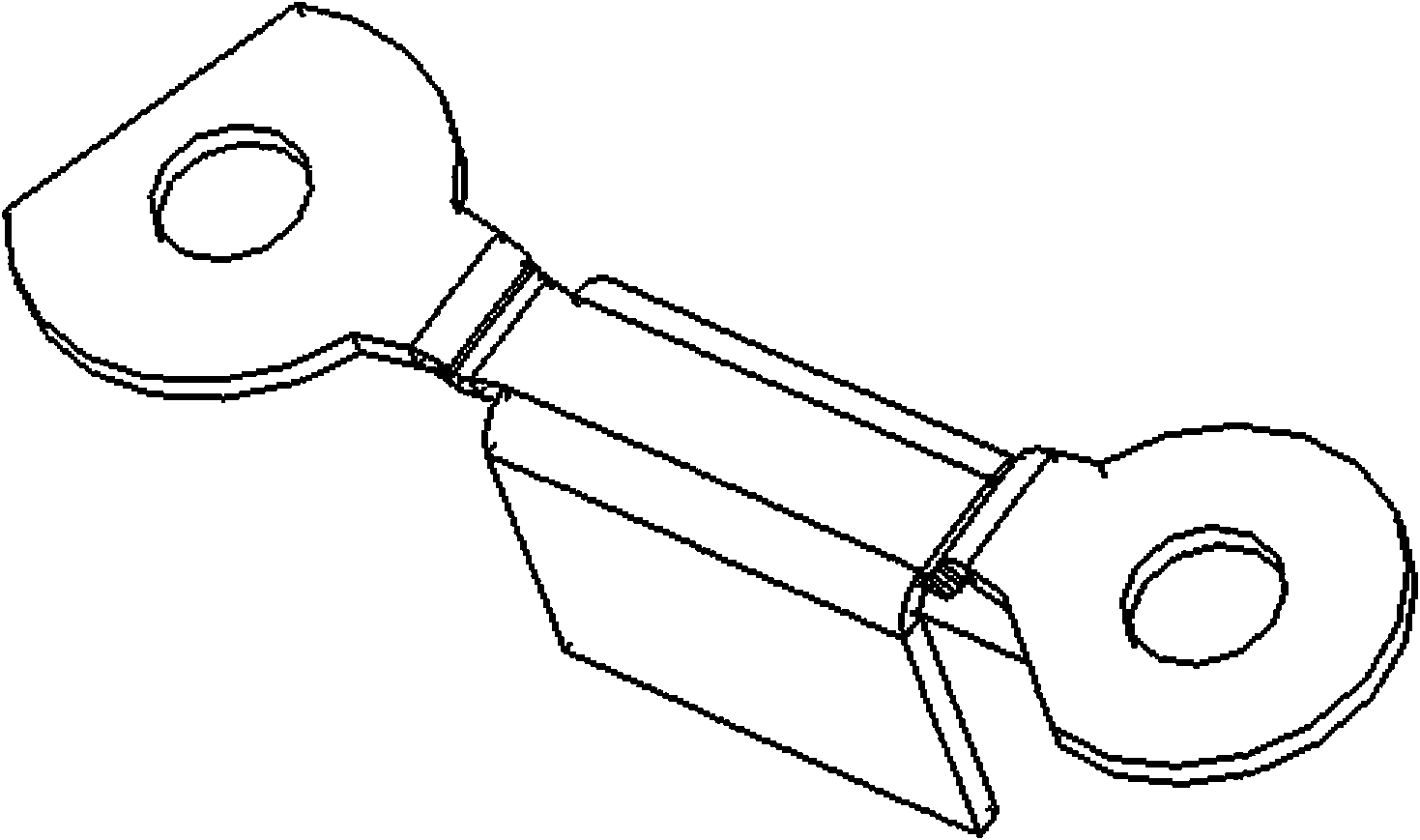

[0017] The invention relates to a contact system with high thermal load capacity, simple structure and low cost. The technical solution is as follows: without any modification of the original housing, a cooling unit is installed under the moving contact. The cooling unit is in direct contact with the moving contact, and the heat is directly guided from the cooling unit to a relatively low temperature area.

[0018] The specific working principle is: in an ideal state, according to the energy conservation formula, namely:

[0019] Q 1 =Q 2

[0020] Q 1 Absorb heat for the cooling unit, Q 2 Dissipate heat for moving contacts. Let the specific heat of the cooling unit be C 1 , with a mass of m 1 , the initial temperature is t 0 , the final temperature is t x , the specific heat of the moving contact is C 2 , with a mass of m 2 , the initial temperature is t h , the final te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com