Sealed rolling bearing

A technology for rolling bearings and sealing lips, which is applied to the sealing of bearing elements, shafts and bearings, and engines. It can solve the problems of inability to prevent rainwater or muddy water from entering, and uneven interference of sealing lips, so as to prevent lubricating oil from leaking and maintain The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

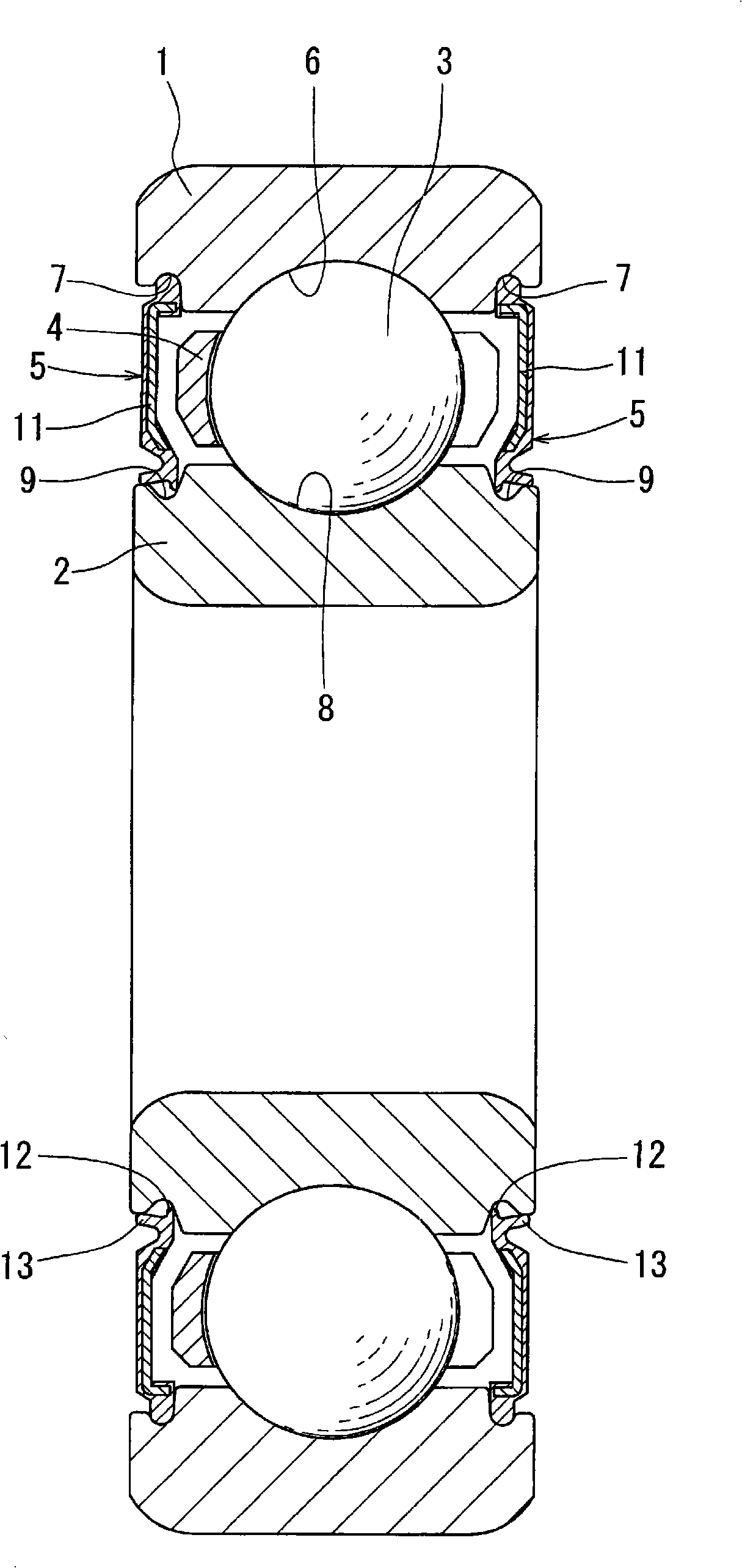

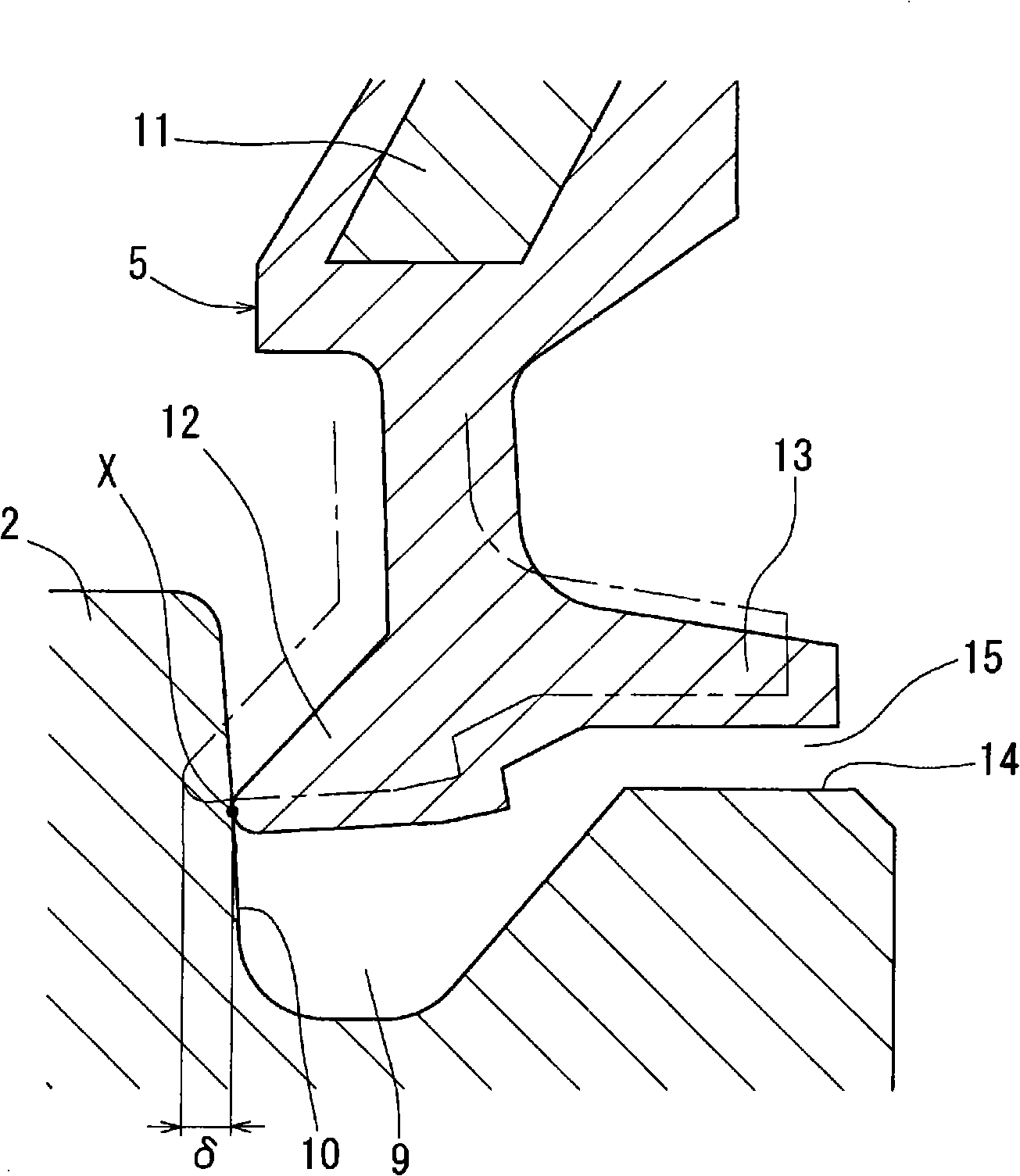

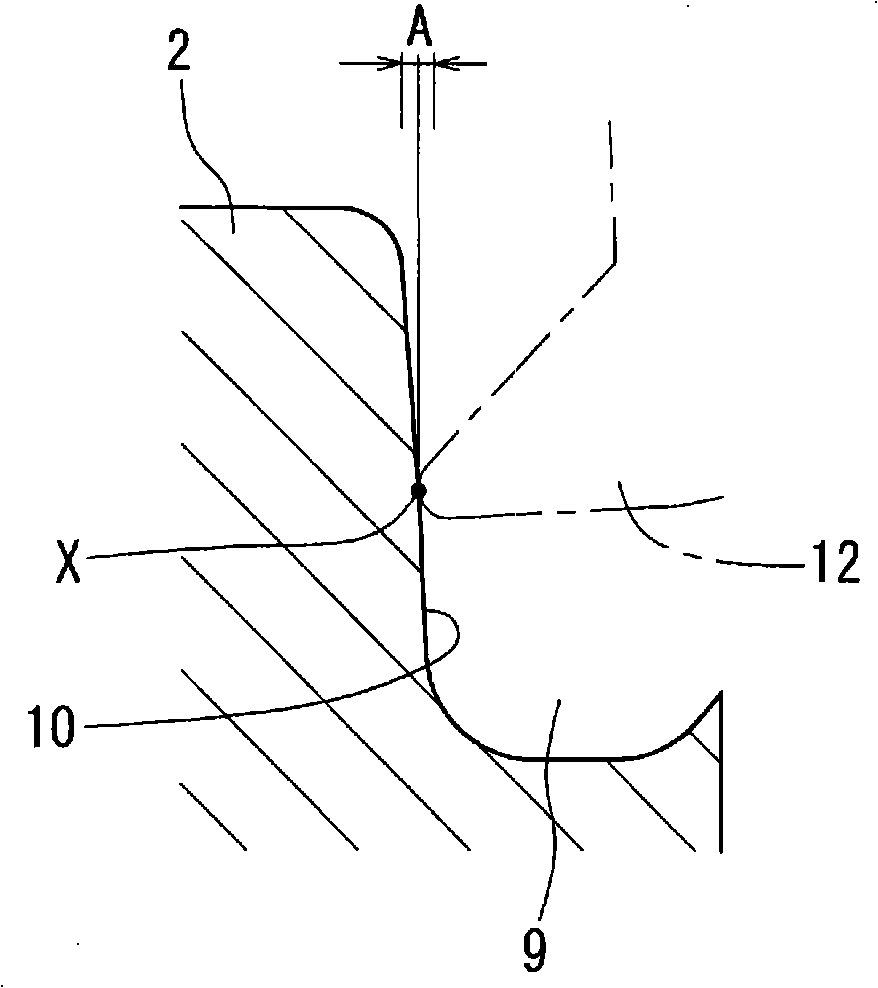

[0018] Embodiments of the present invention will be described below with reference to the drawings. like figure 1 As shown, the sealed rolling bearing consists of an outer ring 1; an inner ring 2 installed inside the outer ring; a rolling body 3 that supports the outer ring 1 and inner ring 2 and enables them to rotate relatively freely; 4 and a pair of sealing members 5 that seal off a bearing space formed between the facing surfaces of the outer ring 1 and the inner ring 2 .

[0019] A raceway groove 6 is formed on the inner diameter surface of the outer ring 1 and a pair of seal grooves 7 are formed on both sides of the raceway groove. On the other hand, on the outer diameter surface of the inner ring 2 is formed a track groove 8 radially opposite to the track groove 6 of the outer ring 1, between the track groove 8 of the inner ring and the track groove 6 of the outer ring. Rolling elements 3 are assembled between them.

[0020] In addition, a pair of annular grooves 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com