Intelligent temperature control device of mold pressing platform variable-frequency power source

A variable frequency power supply and intelligent temperature control technology, applied in electric heating devices, output power conversion devices, electrical components, etc., can solve the problems of unbalanced single-phase power supply and low control accuracy, and improve power efficiency and power factor. Controlling the effect of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

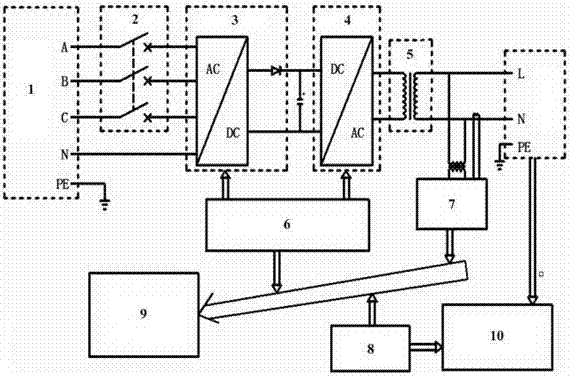

[0034] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

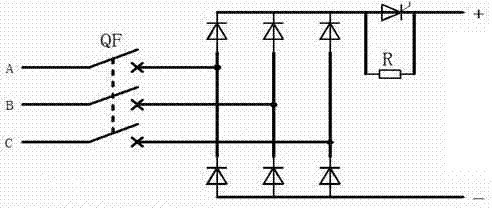

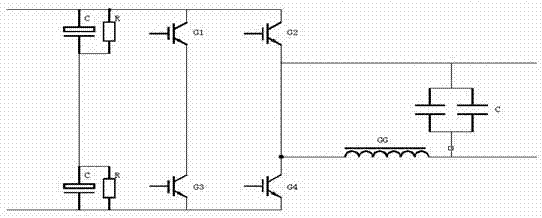

[0035] The schematic diagram of the circuit system of the intelligent temperature control device for the frequency conversion power supply of the molding table in this embodiment is as follows figure 1 shown. The variable frequency power supply intelligent temperature control device of the molding table includes a power supply device for heating the wire rod 10 and a temperature measurement circuit 8 for monitoring the temperature of the wire rod 10; the power supply device includes a three-phase five-wire power supply input terminal 1 , three-phase circuit breaker 2, rectification device 3, inverter device 4, isolation transformer 5 and protection drive circuit 6;

[0036] The three-phase five-wire system power input terminal 1 includes AC power A, AC power B, AC power C, neutral line N and ground wire PE;

[0037] The input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com