Steamturbine comprising a dummy piston

A thrust balancing piston and steam turbine technology, which is applied to steam engine devices, mechanical equipment, engine functions, etc., can solve the problems of unfavorable steam turbines and limited service life, and achieve the effects of improving cooling effect, fast and low-cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

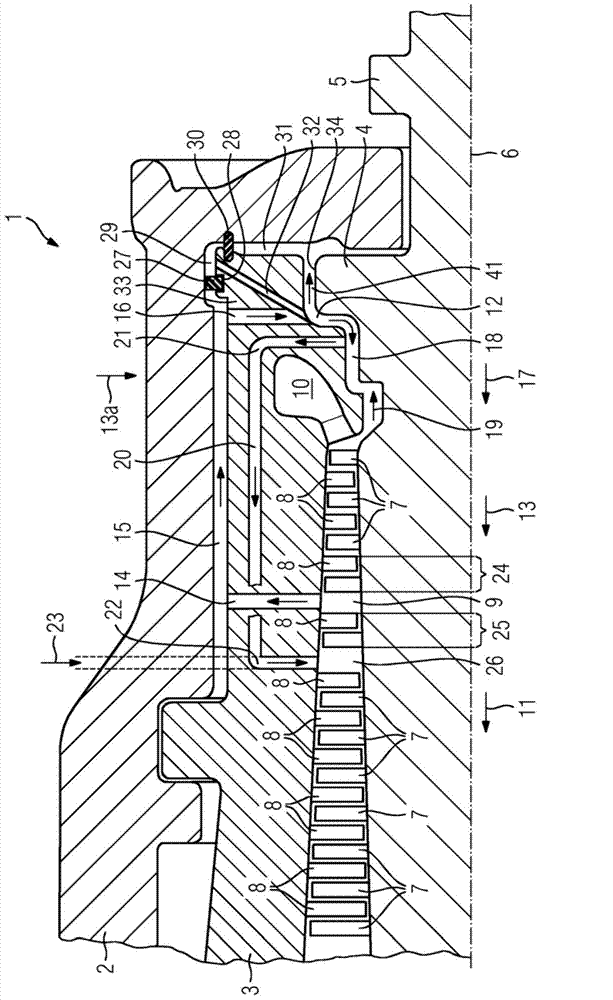

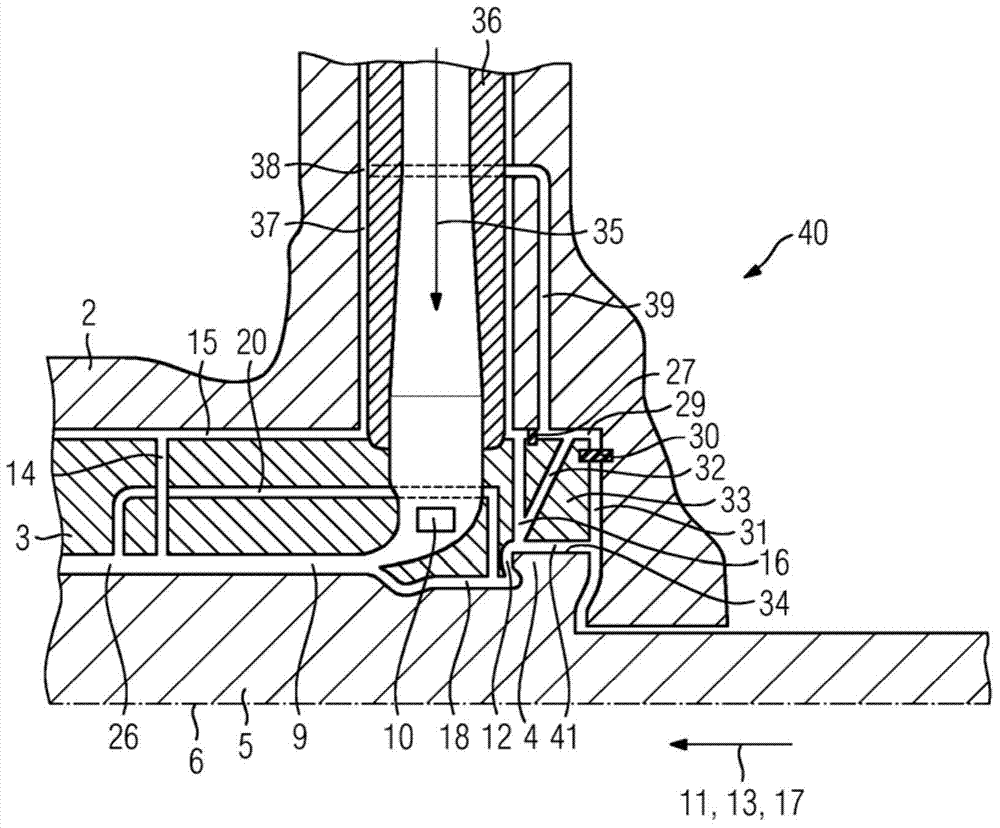

[0020] exist figure 1 A cross section through a steam turbine 1 is depicted in . The steam turbine 1 has an outer casing 2 and an inner casing 3 . The inner housing 3 and the outer housing 2 have live steam supply channels, which are in the figure 2 explained in detail. Inside the inner housing 3 is arranged a rotor 5 with a thrust balancing piston 4 in a rotatably mounted manner. The rotor is generally designed rotationally symmetrically about the axis of rotation 6 . The rotor 5 includes a plurality of rotor blades 7 . The inner housing 3 has a plurality of guide vanes 8 . A flow channel 9 is formed between the inner housing 3 and the rotor 5 . The flow channel 9 comprises a plurality of blade stages, each of which is formed by a row of rotor blades 7 and a row of guide blades 8 .

[0021] The live steam flows via the live steam supply channel into the inlet opening 10 and from there flows through the flow channel 9 in a flow direction 11 which runs substantially par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com