Dust removing machine for textile manufacturing

A dust collector and machine body technology, applied in the field of textile machinery, can solve problems such as polluting the working environment, dropping on the ground, and troubles for processing workers, and achieves the effects of convenient use, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

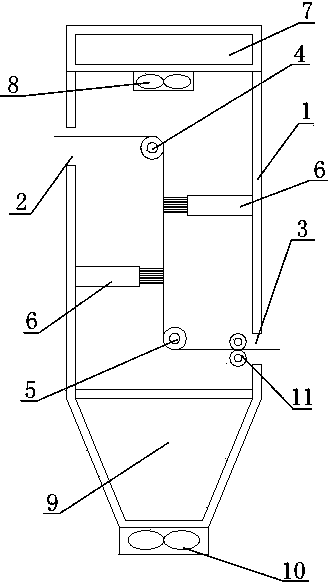

[0014] like figure 1 As shown, the textile dedusting machine of the present invention includes a body 1, a cloth inlet 2 is included above the side wall of the body 1, and a cloth outlet 3 is included below the other side wall, and the middle part of the body 1 is respectively provided with a cloth inlet 2. The first roller shaft 4 and the second roller shaft 5 at the level of the cloth opening 2 and the cloth outlet 3, and the middle part of the side wall in the body 1 also includes two brushes 6 for dust removal; the top of the body 1 is hinged with a top cover 7, The top cover 7 is connected with a blower 8, and the lower part of the body 1 includes an air extraction port 9, which is a trapezoidal structure with a large upper part and a smaller one at the lower part. Two brush rollers 11 in elastic contact are provided.

[0015] In actual work, textiles enter the body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com