Sawing device and control method for horizontal single-slope seamless welded surface of rail

A technology of seamless welding and sawing device, applied in sawing machine devices, metal sawing equipment, manufacturing tools, etc., can solve the problems of non-perpendicular edge of the band saw blade and the cut surface, affecting the service life of the band saw blade, and low repeatability. , to achieve the effect of improving sawing efficiency, good force condition and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific content and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

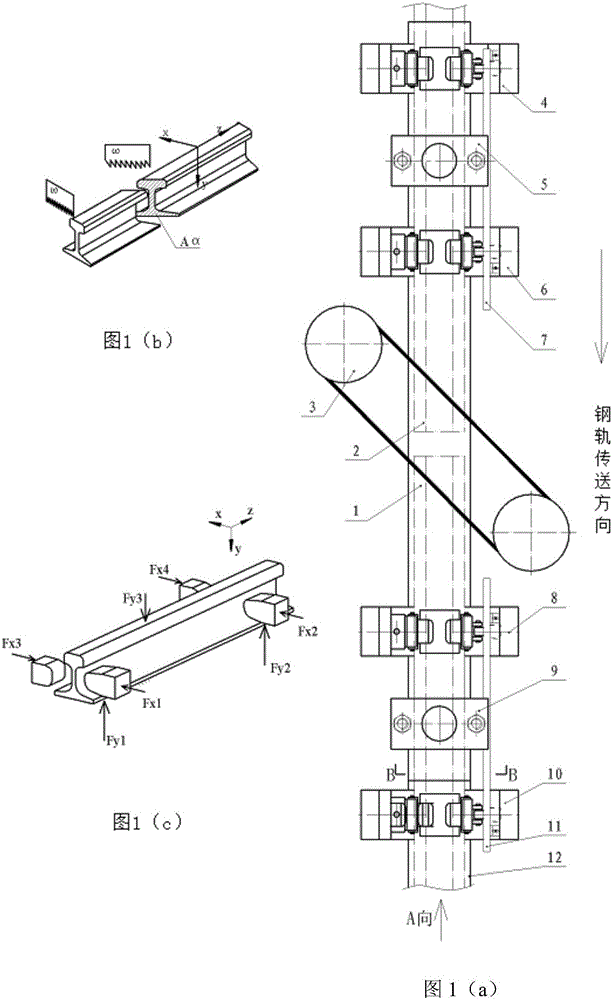

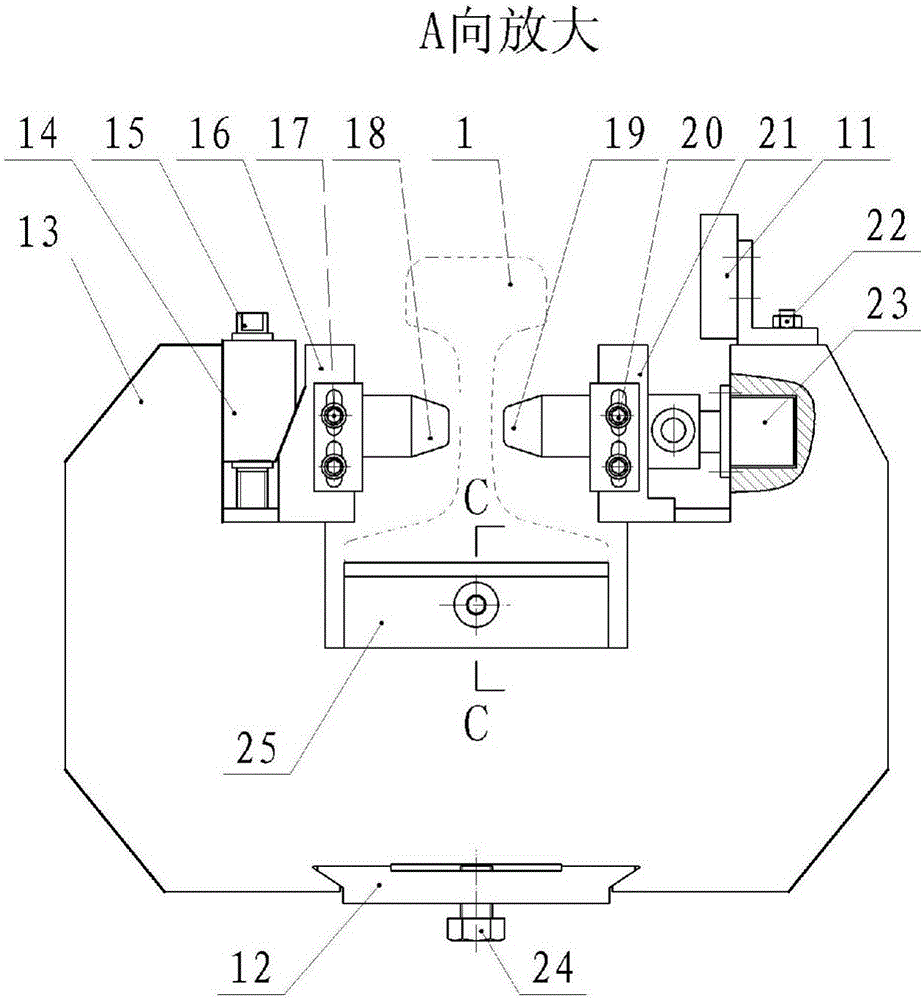

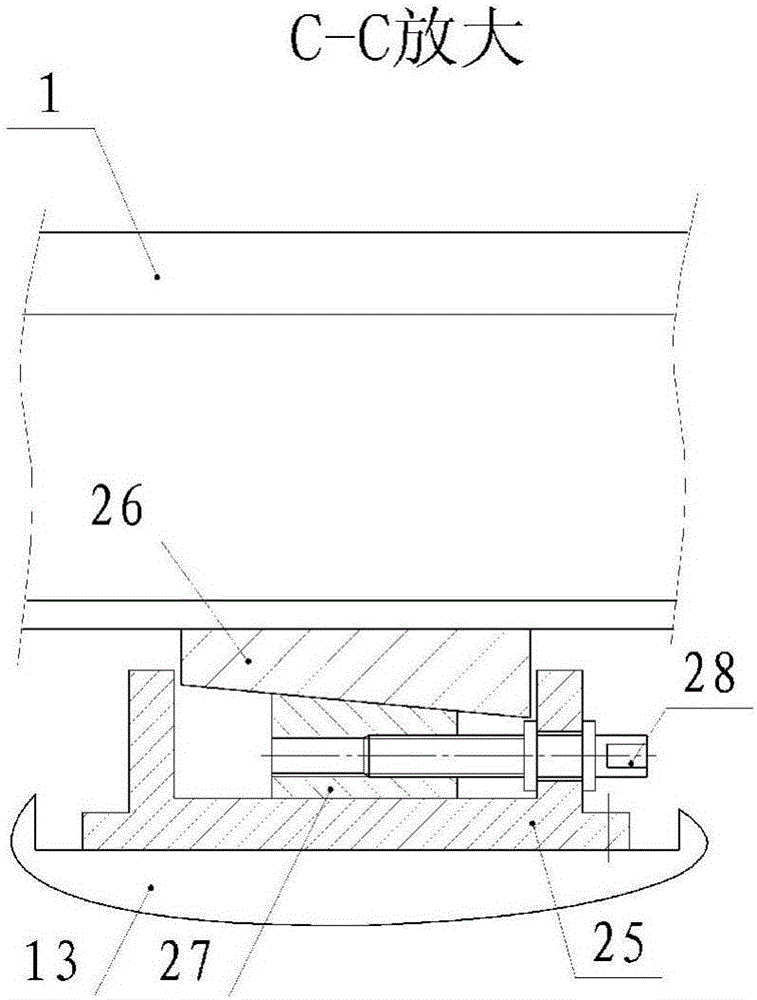

[0047] The rail clamping structure is mainly used for positioning and clamping the sawed end of the rail before sawing: the positioning operation mainly adjusts the posture of the sawed end of the rail so that the longitudinal axis of the sawed end of the rail is aligned with the sawing unit The sawing plane before rotation (rotation angle is 0°) is vertical to ensure accurate sawing angle; the clamping operation is mainly to keep the saw end of the rail stable during the sawing process to ensure the quality of the section and the stability of the sawing angle. Refer to the scheme adopted for the positioning and clamping of the rail Figure 1c , left and right positioning and clamping adopts four-point force, among which Fx1 is opposite to Fx3, Fx2 is opposite to Fx4, up and down positioning and clamping adopts three-point for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com