Anti-disengagement clamp with self-locking type worm

A self-locking, worm technology, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of unreliable clamping and easy loosening, and achieve the effects of high positioning accuracy, reliable anti-loosening structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

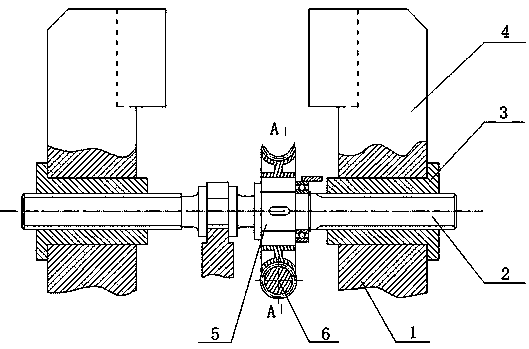

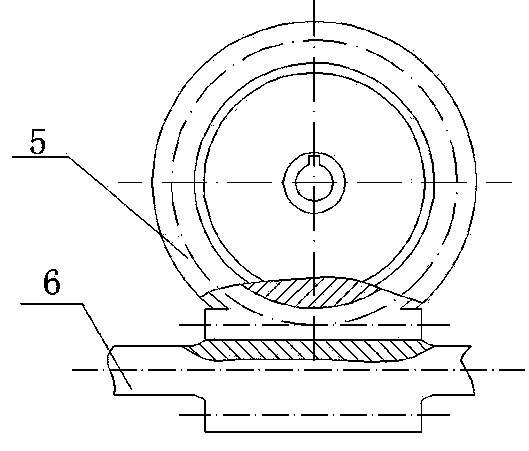

[0018] Such as figure 1 , figure 2 As shown, the worm self-locking anti-loosening fixture includes a fixture seat 1, a screw rod 2, a moving block 3, and a clamping block 4. On the concave edge of the upper end of the block 3, the screw 2 meshes with the moving block 3, and also includes a worm wheel 5 and a worm 6. The worm wheel 5 is assembled on the screw 2 through a key, and the worm 6 is assembled on the fixture seat 1 through a rolling bearing. And mesh with worm gear 5.

[0019] The helix angle of the worm 6 is smaller than the equivalent friction angle of the meshing surface with the worm wheel 5 . The worm 6 is a single-head worm, and its cross-sectional tooth profile is an Archimedes spiral.

Embodiment 2

[0021] Such as figure 1 , figure 2 As shown, the worm self-locking anti-loosening fixture includes a fixture seat 1, a screw rod 2, a moving block 3, and a clamping block 4. On the concave edge of the upper end of the block 3, the screw 2 meshes with the moving block 3, and also includes a worm wheel 5 and a worm 6. The worm wheel 5 is assembled on the screw 2 through a key, and the worm 6 is assembled on the fixture seat 1 through a rolling bearing. And mesh with worm gear 5.

[0022] The helix angle of the worm 6 is smaller than the equivalent friction angle of the meshing surface with the worm wheel 5 . The worm 6 is a double-headed worm, and its cross-sectional tooth profile is a concave arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com