Car sliding door sealing strip

A technology for sealing strips and sliding doors, which is used in sealing devices, engine sealing, vehicle parts, etc., can solve the problems of insufficient tight fitting of sliding door sealing strips, easy to fall off, etc., to increase practical performance, prevent stress concentration, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments, and the described embodiments are only a part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, other used embodiments obtained by persons of ordinary skill in the art without creative efforts all belong to the protection scope of the present invention.

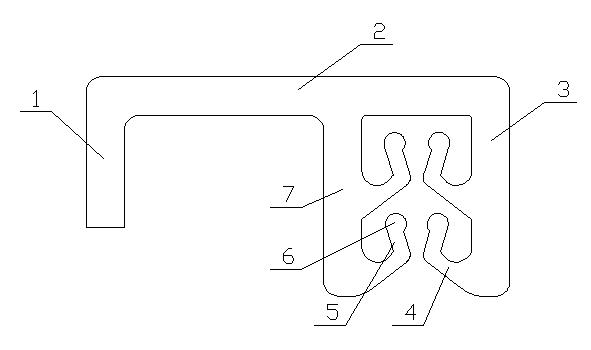

[0017] The automobile sliding door sealing strip of the present invention, the cross section of the sealing strip is door-shaped, including a supporting part, a clamping part and a bending part, and the clamping part is two mutually parallel first clamping sides and a second clamping part. side, the second clamping side is located between the first clamping side and the bending part; the first clamping side and the second clamping side are provided with corresponding convex corrugations on the opposite surface, and the convex corrugations are arranged obliquely on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com