Control method for improving performance of automatic weighing and bagging system

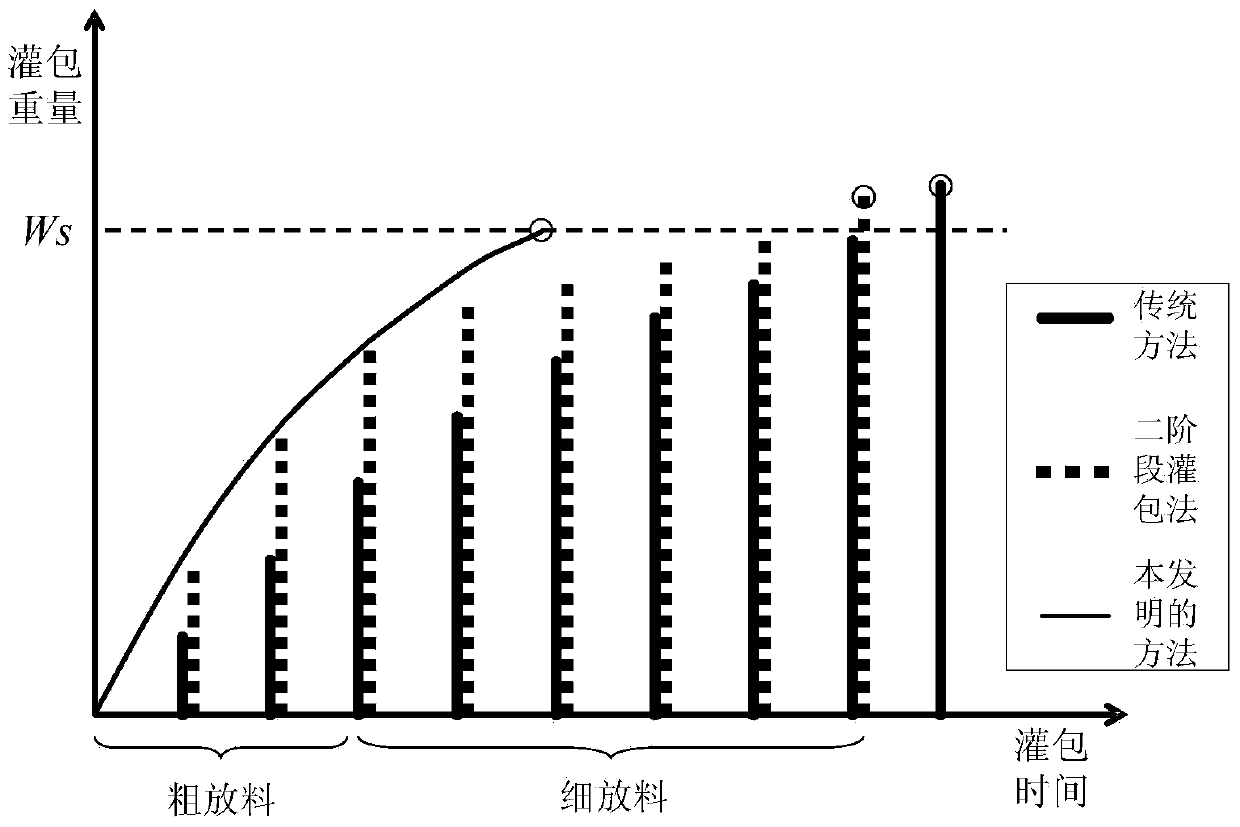

A technology of automatic weighing and system performance, applied in the direction of packaging, transportation and packaging, packaged item types, etc., can solve problems such as extra impulse, large error, and slow speed in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

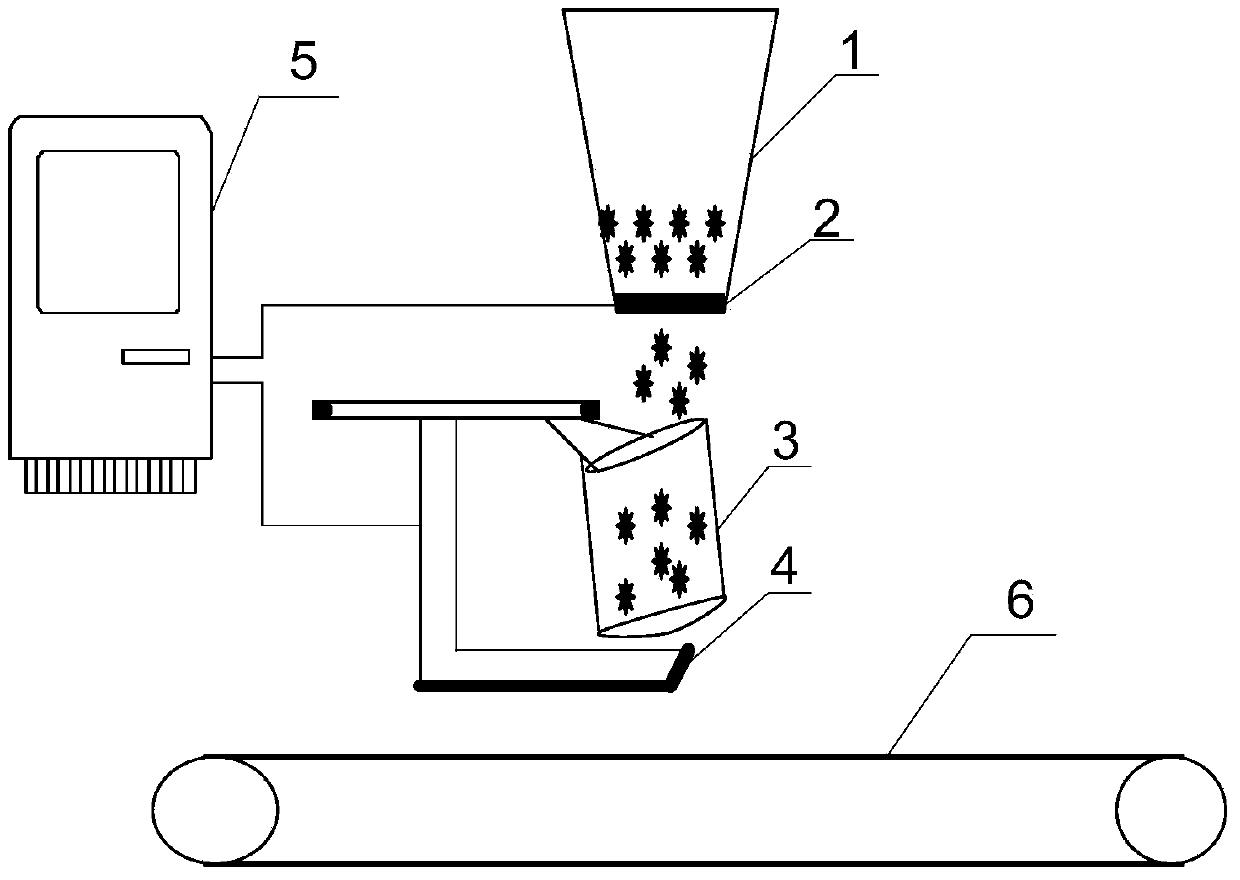

[0046] Such as figure 1 As shown, when the automatic weighing and bag filling system is working, the material is first transported to the feeding hopper 1, and then the controller 5 controls the feeding hopper valve 2, opens the feeding hopper valve 2, and the material falls into the cloth bag 3 at a certain flow rate, and then During the feeding process, the weighing device 4 weighs according to a certain frequency, and sends the measured data to the controller 5 . In the traditional control method, when the difference between the measured weight and the set value of the filling bag weight is less than a certain threshold, the controller 5 controls the valve of the feeding hopper to close, and the bag filling is completed. After the bag filling is completed, the cloth bag 3 is sent to the subsequent The link is sealed and palletized.

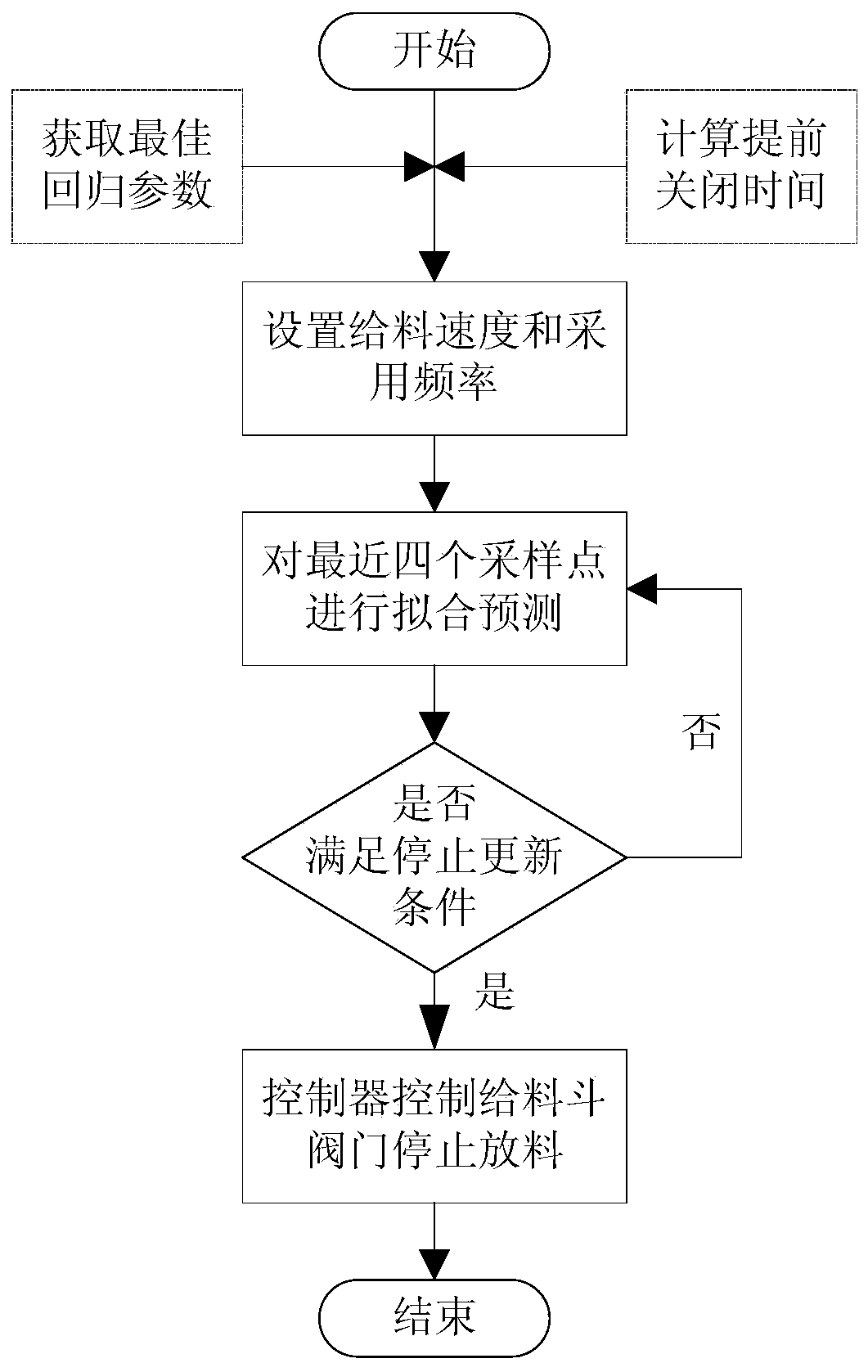

[0047] Such as figure 2 As shown, it is a flow chart of the method provided by the present invention, and the automatic weighing bag fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com