Material flow circulating system for filter candle empty and solid trays

A technology of circulation system and feeding tray, applied in the field of tobacco production, can solve problems such as inconvenience, and achieve the effect of improving the efficiency of operation and management and reducing the intensity of manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

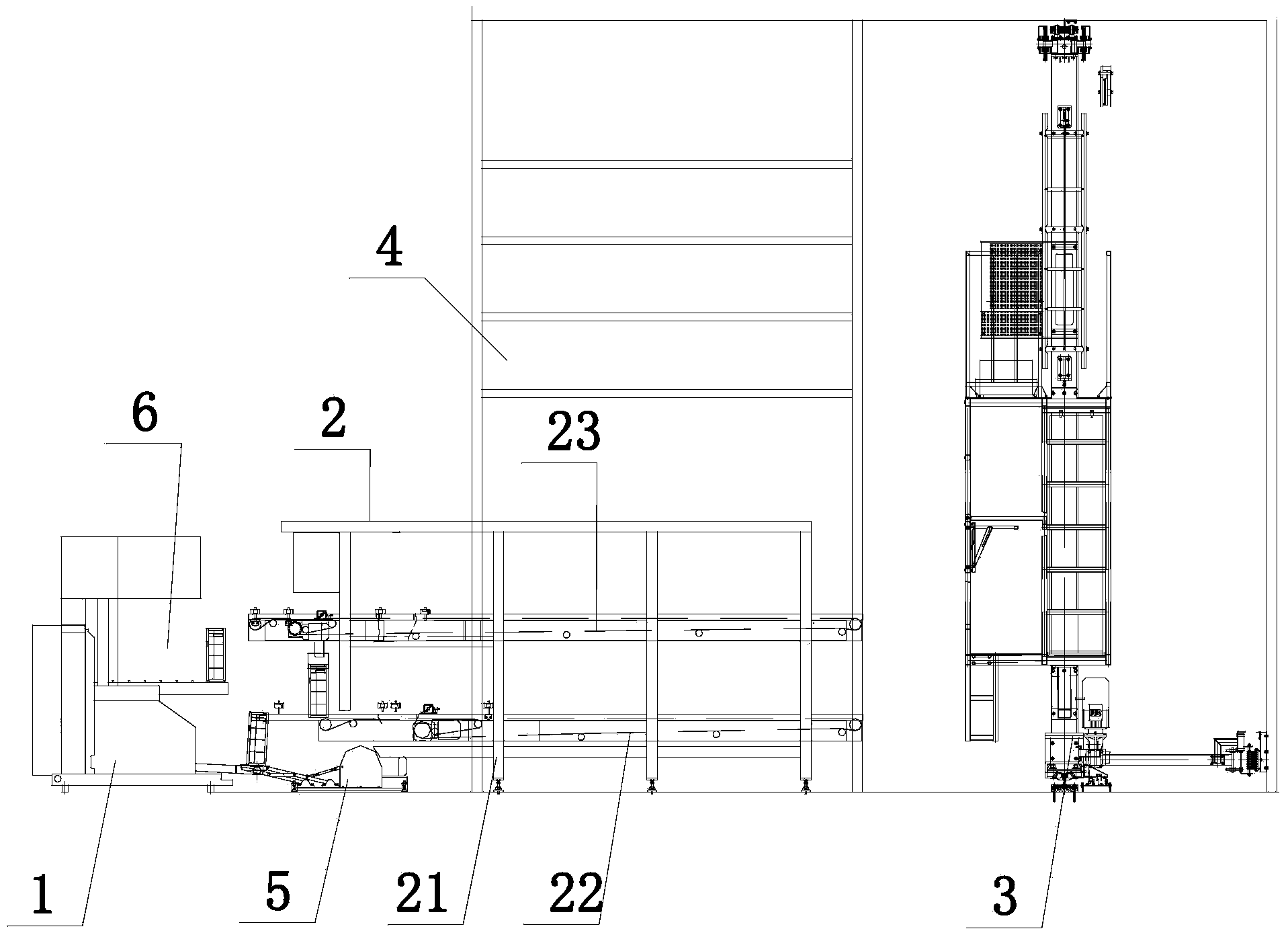

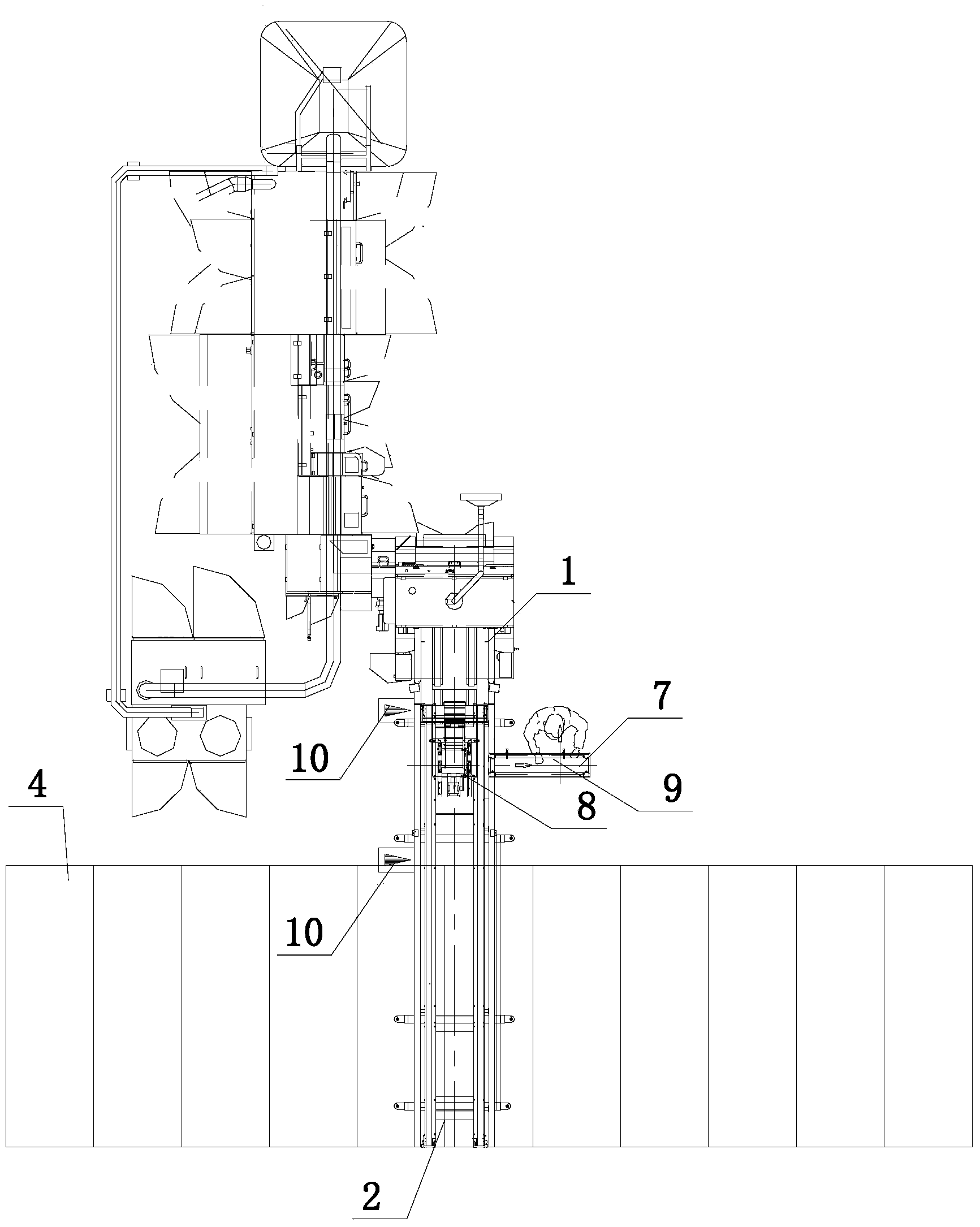

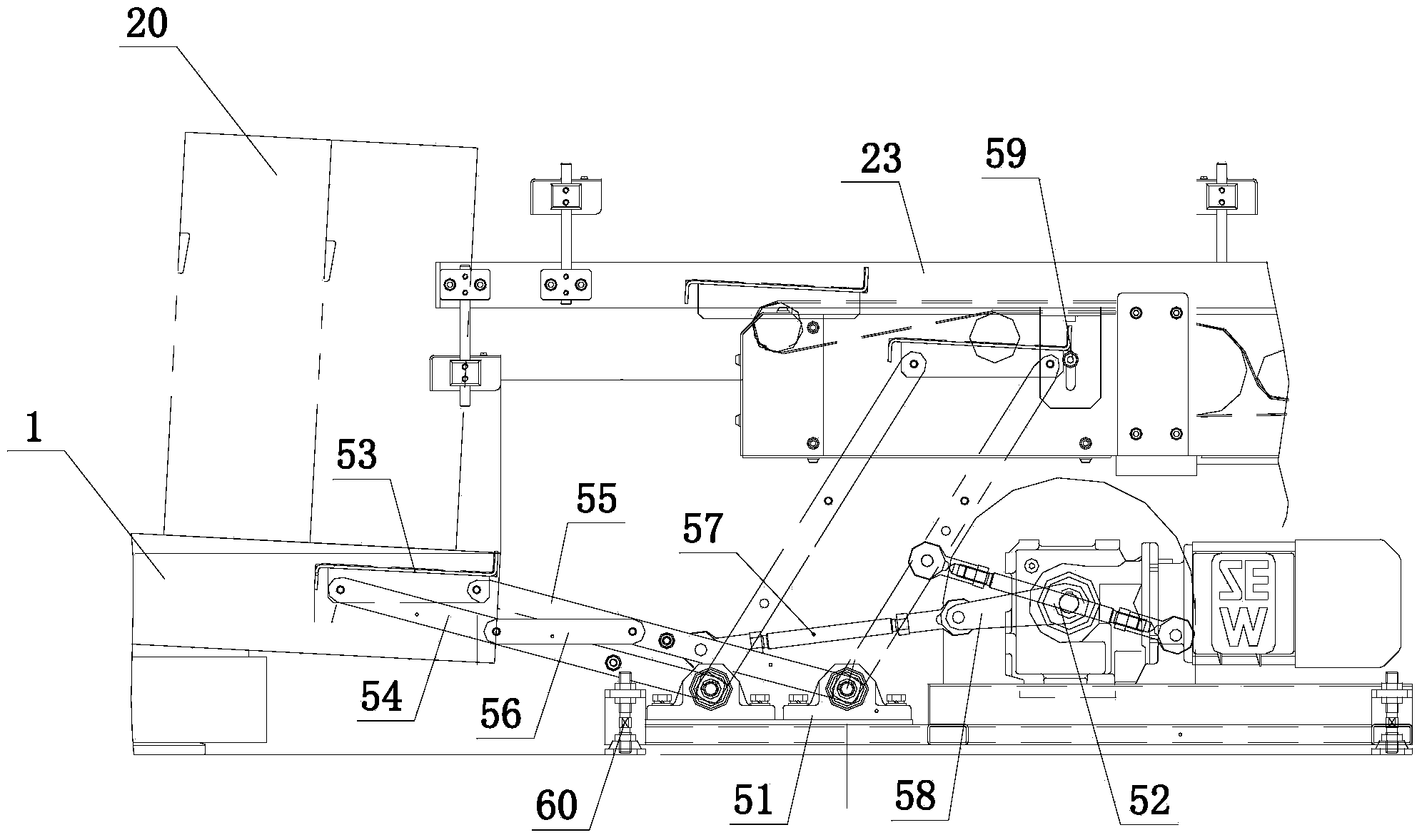

[0024] Such as figure 1 , figure 2 Shown is a logistics circulation system for empty filter rods and solid material trays. The system includes a forming machine loading machine 1, a filter rod tray conveyor 2, a filter rod stacker 3 and an elevated warehouse 5, and the filter rod trays are Conveyor 2 comprises frame 21, lower belt conveyor 22 and upper belt conveyor 23, upper belt conveyor 23 and lower belt conveyor 22 are respectively fixedly arranged on the upper and lower sides of frame 21, lower belt conveyor 22 and all The forming machine disc loading machine 1 described above is connected by setting a multi-link lifting mechanism 5 . The start and end of the lower belt conveyor 22 are respectively provided with RFID writing devices 9, 10, and the RFID writing devices 9, 10 can write and read filter rod information. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com