Conveying device

A technology of conveying device and conveyor belt, which is applied in the direction of transportation and packaging, object supply, pile separation, etc., and can solve problems such as poor detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the drawings. Through the description of the specific implementation, the technical means and functions adopted by the present invention to achieve the predetermined purpose can be understood more deeply and specifically. However, the attached drawings are only for reference and illustration, and are not used to limit the present invention.

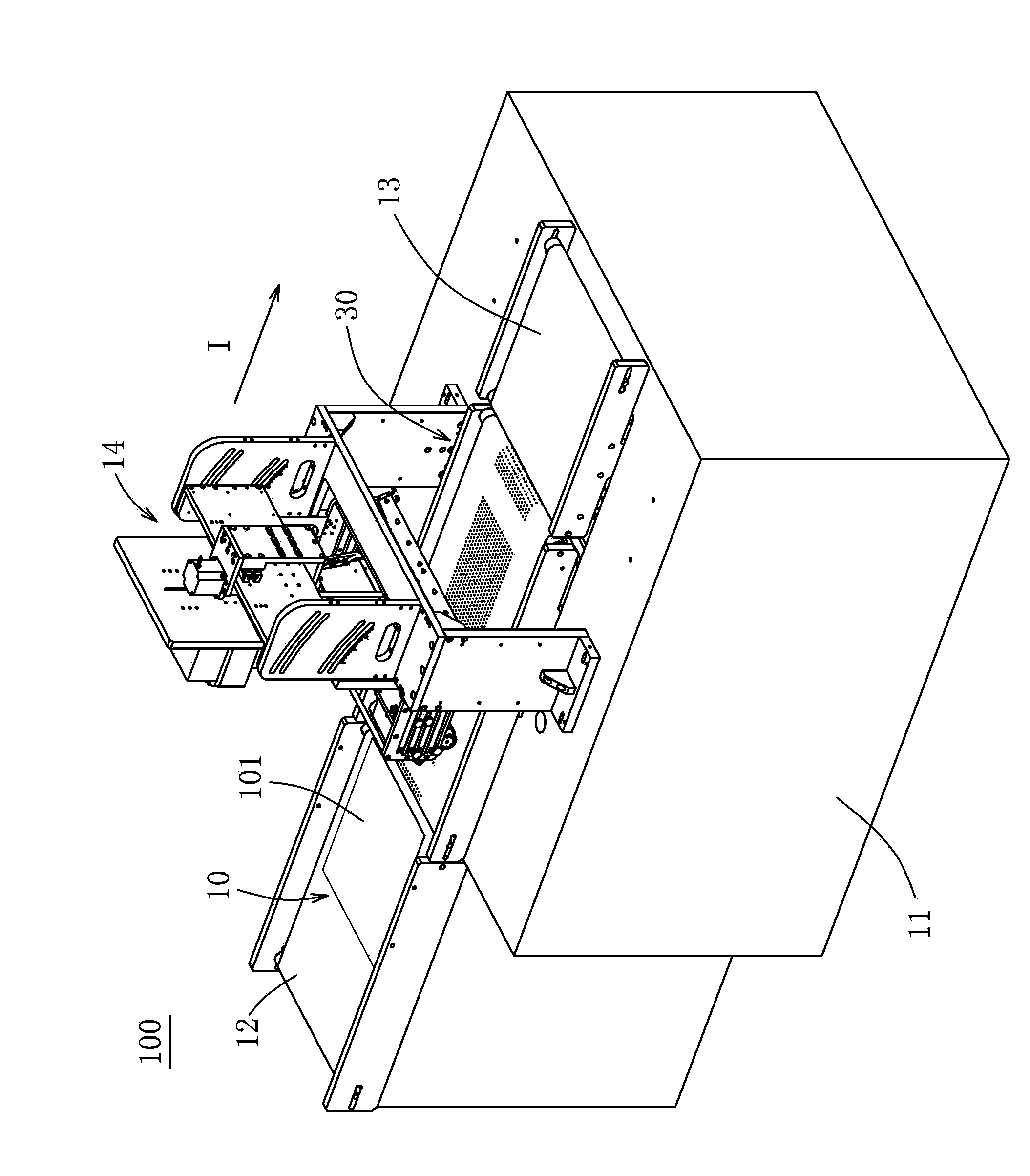

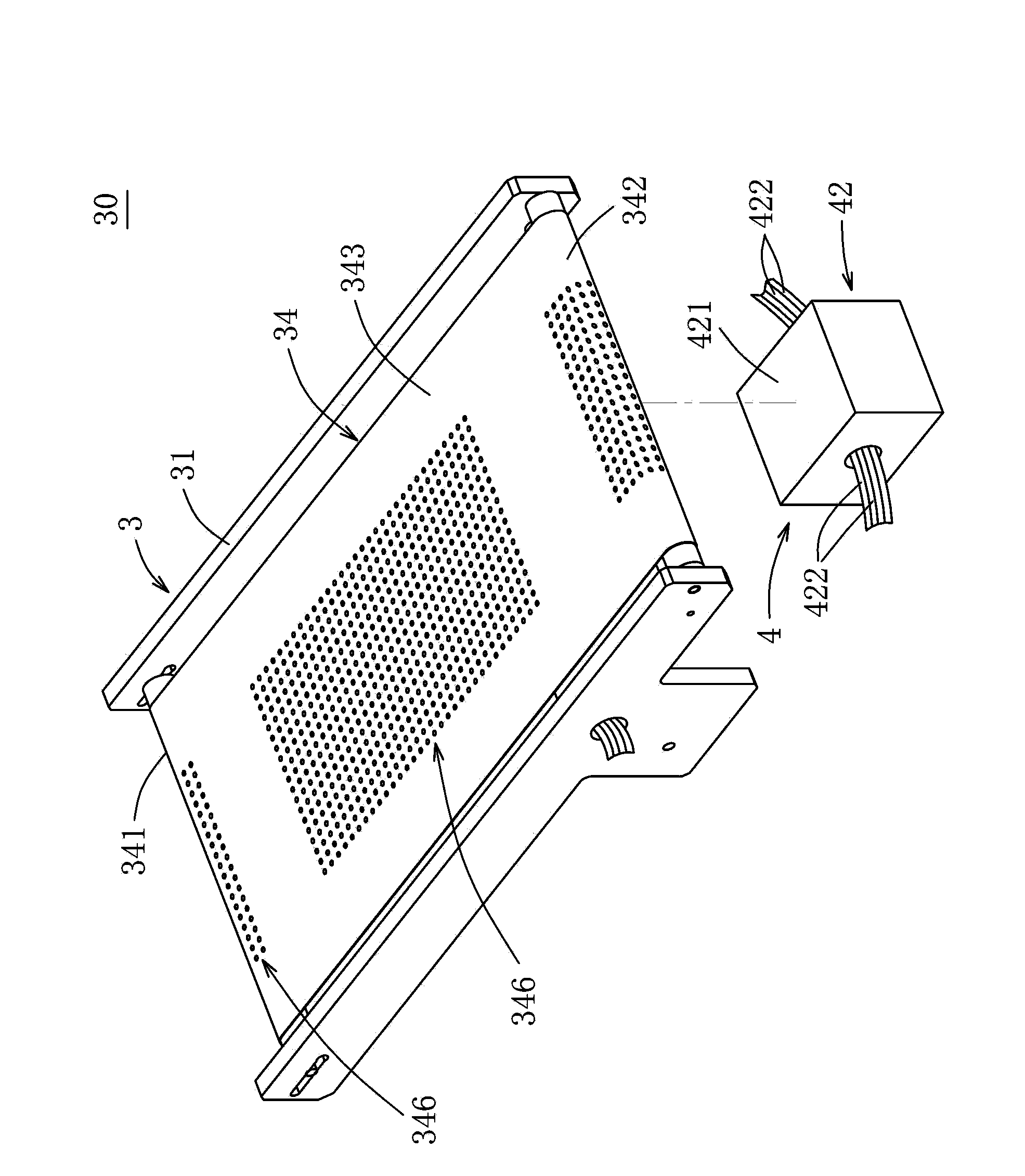

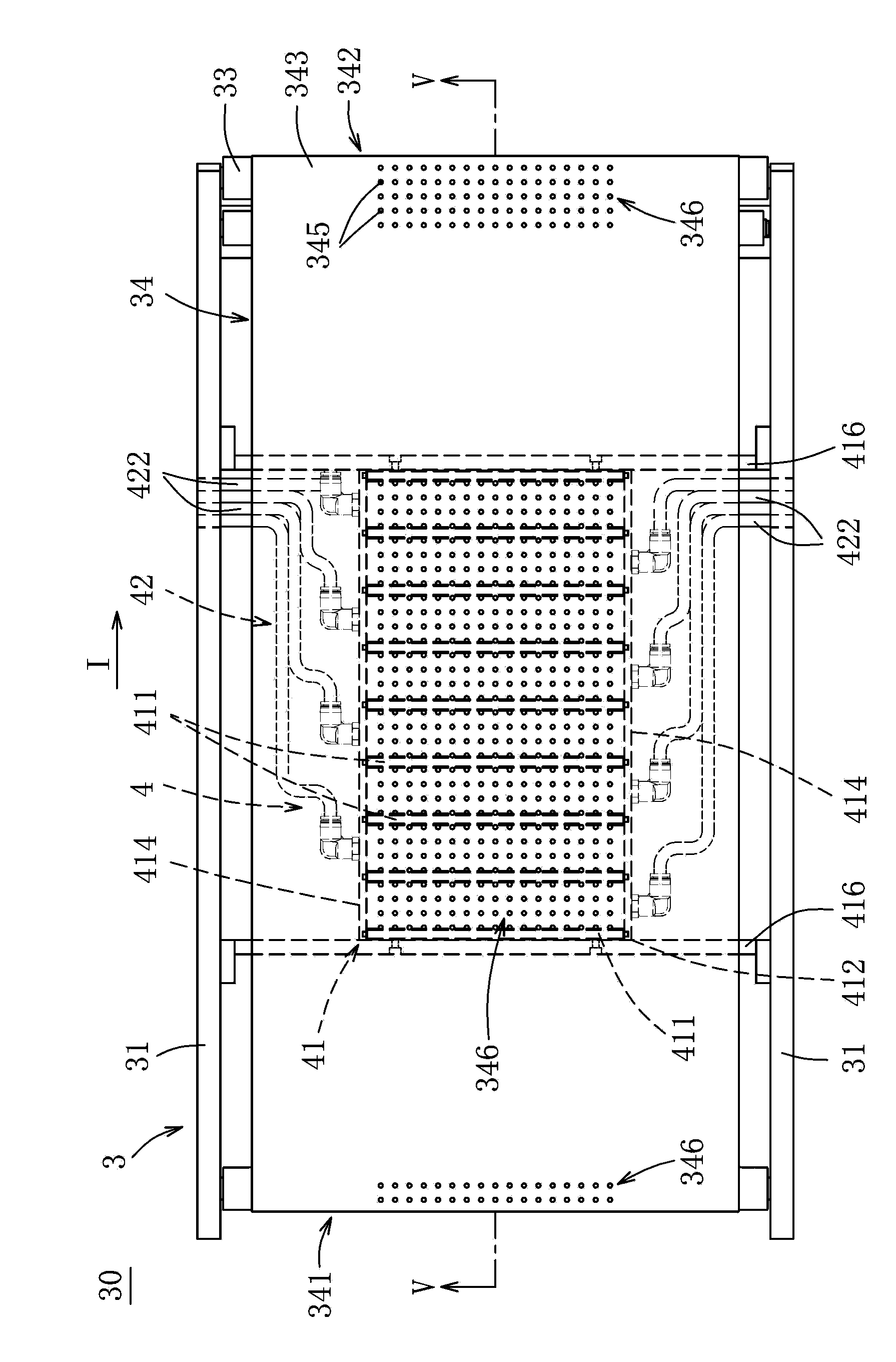

[0029] Such as figure 1 Shown is the first preferred embodiment of the conveying device of the present invention. The conveying device 30 is applied to a testing device 100. The testing device 100 includes a machine base 11 and an inlet respectively arranged on the top of the machine base 11. Material conveyor belt 12, a discharge conveyor belt 13 and an optical detection device 14.

[0030] The conveying device 30 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com