A dynamic shaft seat of a viscosity machine

A viscosity machine and shaft seat technology, which is applied in the direction of mechanical equipment, bearing components, shafts and bearings, etc., can solve problems such as unstable operation of the viscosity machine, affecting product quality, and unreasonable structure, so as to achieve reasonable structure, meet production needs, Design the right effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

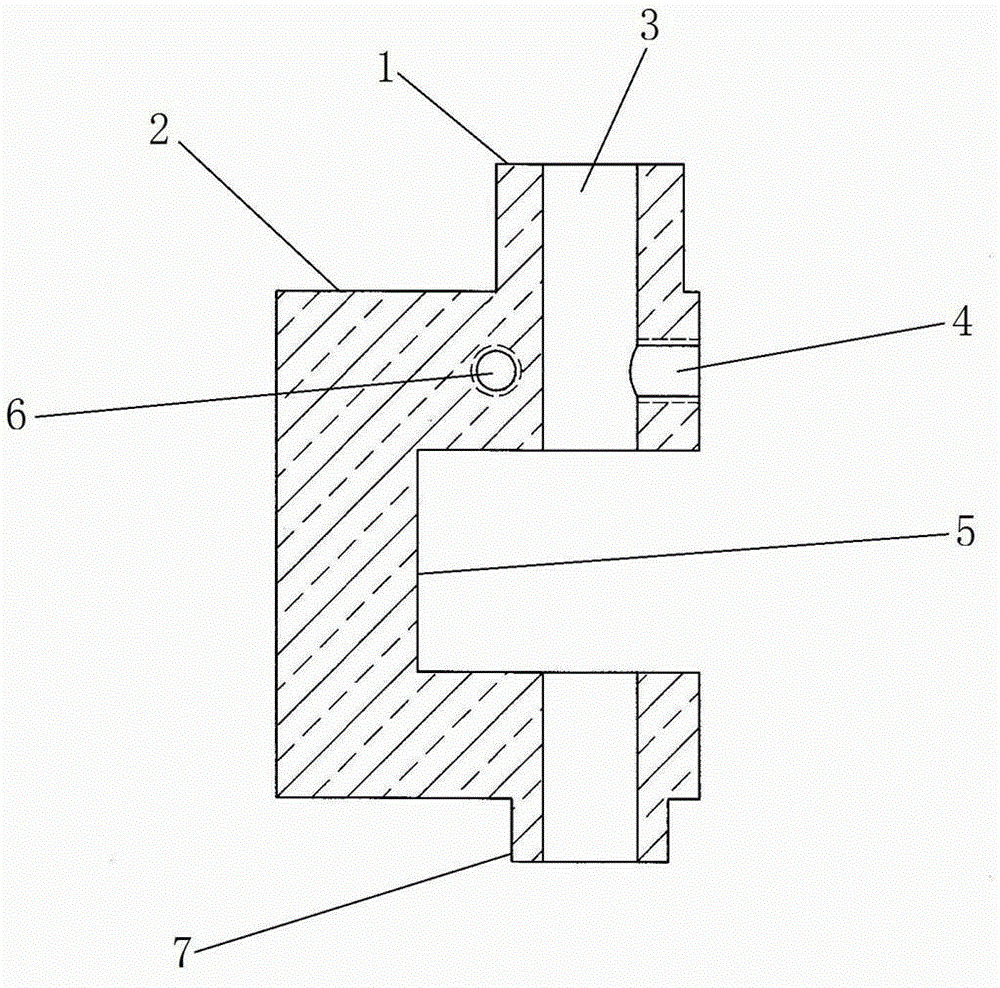

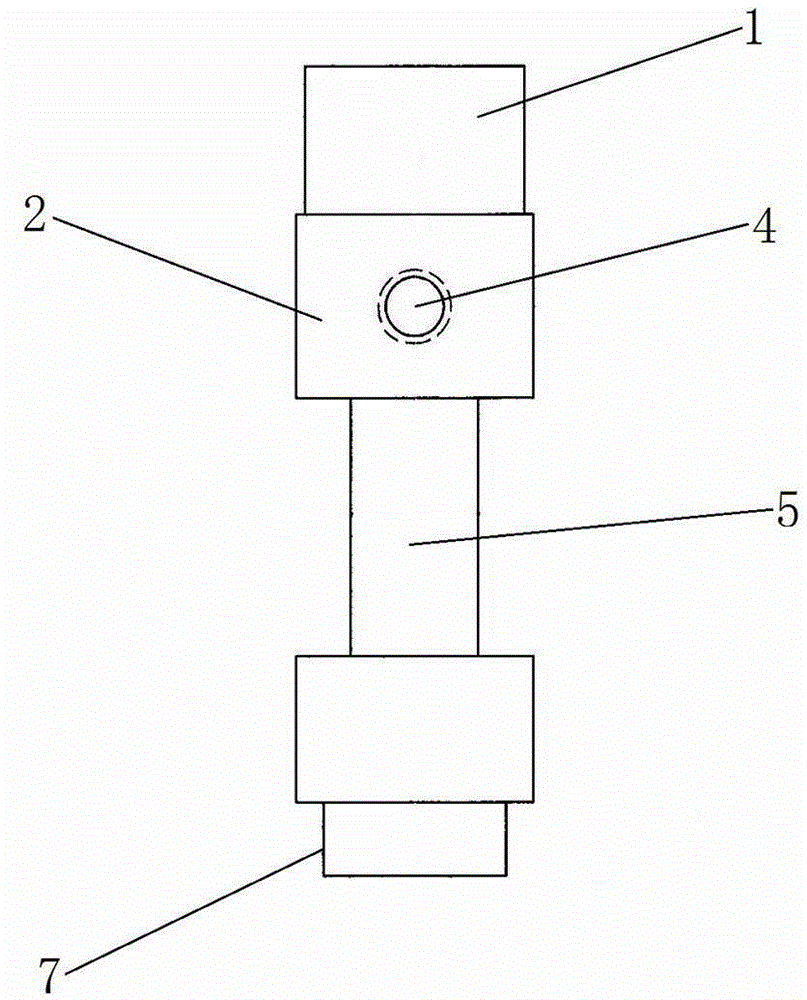

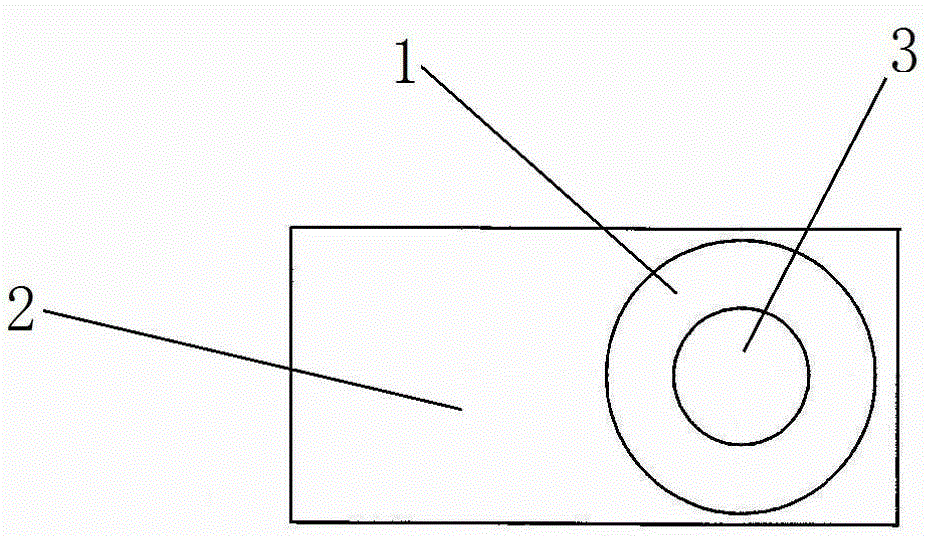

[0012] A dynamic rotating shaft seat of a viscosity machine, including a shaft seat and a round through hole, characterized in that the shaft seat is composed of a cylindrical seat 1 and a cuboid seat 2, and the cylindrical seat 1 is embraced by the rectangular parallelepiped seat 2; the cylindrical seat 1 exceeds The upper part of the cylindrical seat 1 on the top of the rectangular parallelepiped seat 2, the diameter of the outer circumference of the upper part of the cylindrical seat 1 is 6 mm, and the upper circular surface of the upper part of the cylindrical seat 1 is 4 mm from the top of the rectangular parallelepiped seat 2, and The lower part 7 of the cylindrical seat 1 beyond the bottom of the rectangular parallelepiped seat 2, the diameter of the outer circumference of the lower part 7 of the cylindrical seat 1 is 5mm, and the distance from the lower circular surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com