Valve capable of avoiding water storage at water outlets after shutting off

A water outlet and valve closing technology, applied in the direction of valve operation/release devices, valve details, multi-way valves, etc., can solve the problems of residual water in the outlet pipeline that cannot be exhausted by users, adverse effects, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

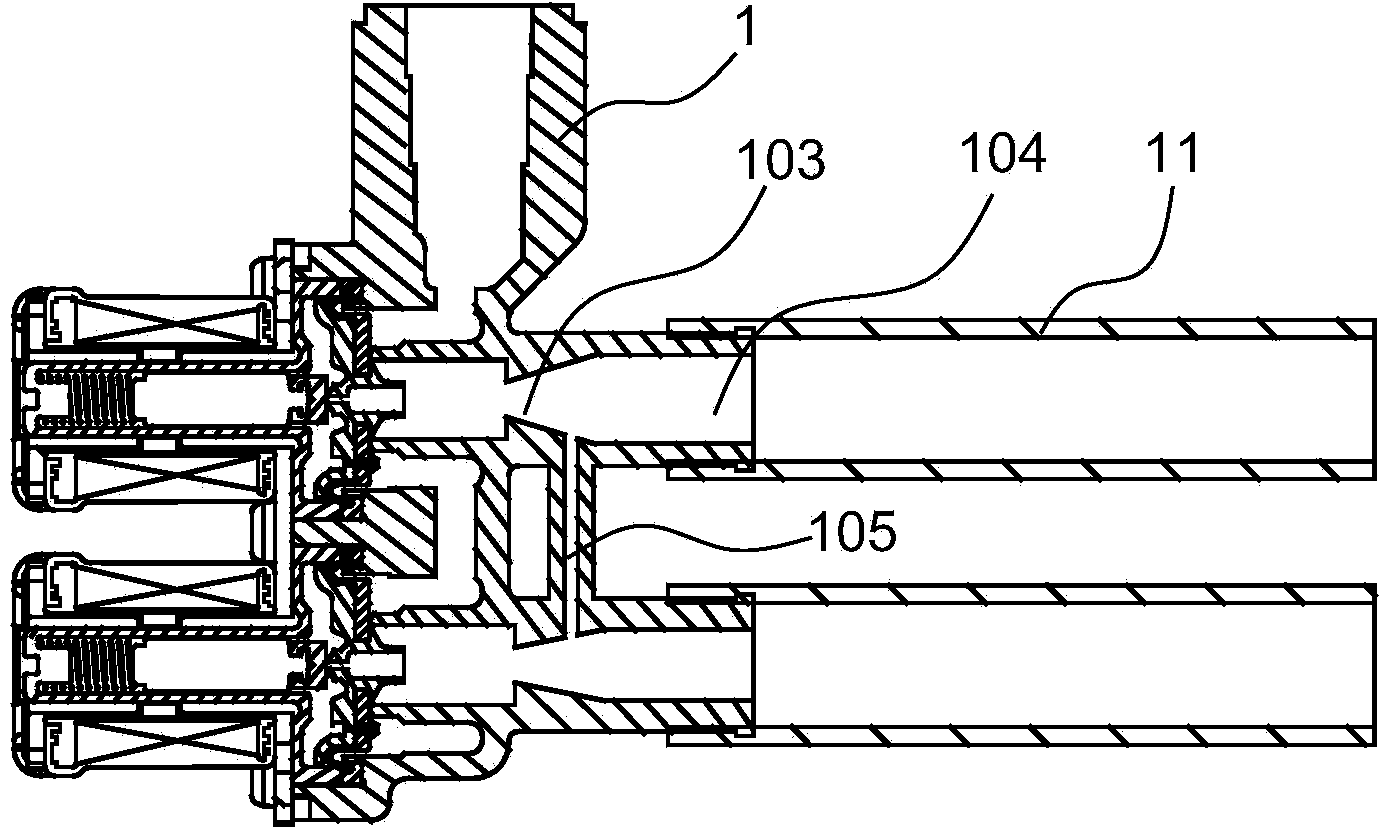

Embodiment 1

[0021] After the valve is closed, there is no water in the water outlet. The valve body 1 is provided with a water inlet 101, a water supply chamber 106 connected with the water inlet, and two valves with the same structure. The valve consists of a valve seat 102, a valve for opening and closing the valve seat Disc, water outlet 104, back pressure chamber 4 and the pilot valve of the discharge back pressure chamber. The valve seat is set on the valve body and located in the water supply chamber 106. The valve disc is connected to the valve body and corresponds to the valve seat. The water outlet is set on the valve body. body and connected to the port of the valve seat, the water outlet is connected with a hose 11, the back pressure chamber 4 is formed in the valve body and is located in the direction of the back pressure surface of the valve disc; the valve disc is composed of a diaphragm 2 and a diaphragm plate 3, the diaphragm The sealing surface corresponds to the positive ...

Embodiment 2

[0025] The valve of this example is different from the previous example in that the water outlets of the two valves each have a bypass port, and the conduction pipe is an external connecting pipe connected to the two bypass ports, and the external pressing pipe is a hose . Other constructions are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com