Pipe crawler

A trolley and pipeline technology, applied in the direction of special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of low detection efficiency, high labor intensity of pipeline inspection, and easy missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

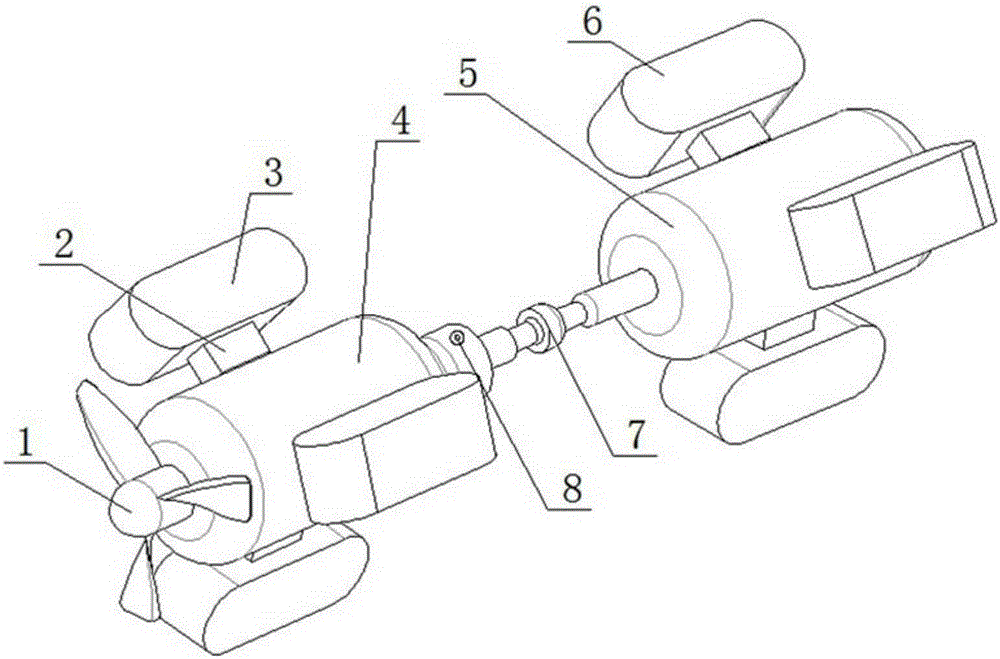

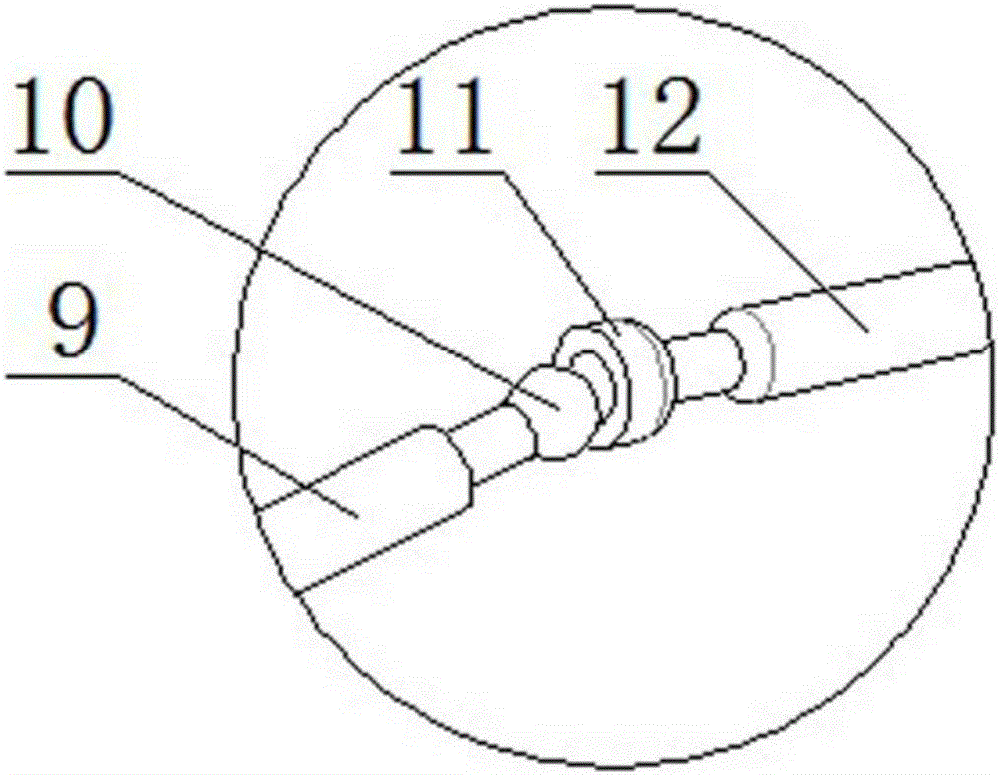

[0012] according to Figure 1~2 The mechanism of the present invention is explained in detail. The pipe crawling trolley includes a front casing 4, a rear casing 5, a connecting part 7 for connecting the front casing 4 and the rear casing 5, a walking device, a camera 8 and other parts. Wherein, the connecting portion 7 includes a front connecting rod 9 installed on the front housing 4 and a rear connecting rod 12 installed on the rear housing 5 . The end of the front connecting rod 9 is provided with a joint 10, and the end of the rear connecting rod 12 is provided with a joint groove 11 matched with the joint 10. The joint 10 is embedded in the joint groove 11, and can 11 turn. The side wall of front housing 4 is evenly distributed with three sets of front running gear 3 circumferentially, and front running gear 3 is installed on the front housing 4 side walls by telescopic mechanism 2 . The side wall of the rear housing 5 is evenly distributed with three sets of rear run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com