Precise construction sampling method for cantilever bridge construction

A cantilever and precise technology, applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve problems such as engineering influence and error, and achieve the effect of solving accuracy problems, ensuring accuracy, and reducing error probability and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

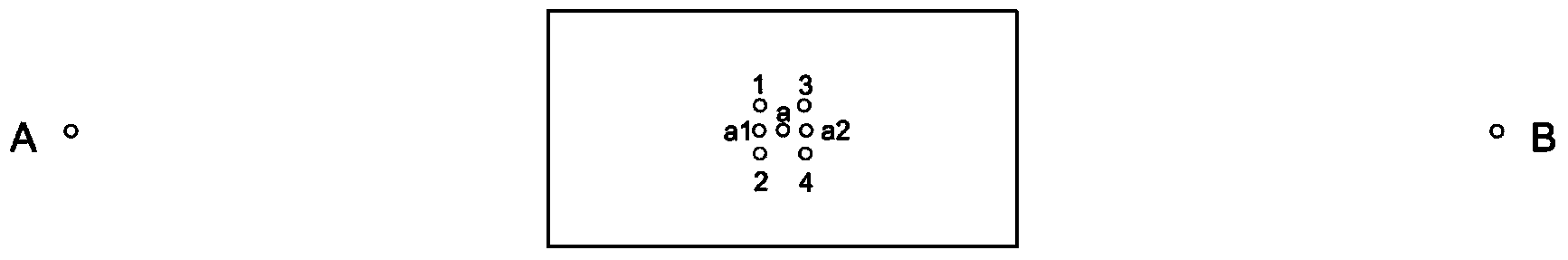

[0016] see figure 1 , the present invention comprises the following steps:

[0017] Step 1: Set up a total station on the obligatory centering observation pier near the construction site of the cantilever beam bridge for observation, and stake out two control points for the precise construction and lofting of the cantilever beam bridge. The two control points are the cantilever beam bridge The extension line of the axis is at the stable geological section of the bridge head in two opposite directions of the cantilever beam bridge and can observe each other;

[0018] Step 2: Set the pre-stakeout point as the midpoint a of the length of the cantilever beam section along the bridge axis. Let one of the control points be A and the other control point be B. In theory, the three points A, a, and B are collinear. Set up a total station at control point A, aim at control point B on the left side of the face to determine the first line of sight direction, and then in the first line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com