Method for manufacturing molded products using coffee grounds

A processing method and technology for coffee grounds are applied in the field of processing molded products using coffee grounds, and can solve the problems of cumbersome processing procedures, low utilization frequency, low demand and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

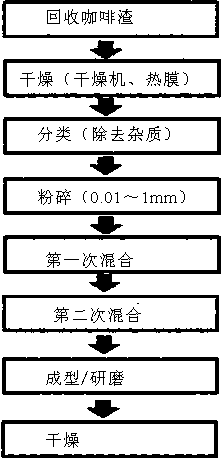

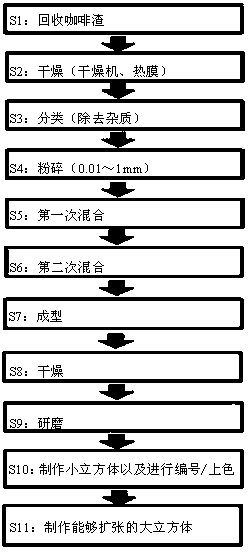

[0014] The present invention relates to a method for processing molded products utilizing coffee grounds, such as figure 1 As shown, the present invention is characterized in that it includes: the step of recovering coffee grounds from a coffee specialty store; the step of drying through a dryer and a hot film above 15°C; the step of classifying the particles of coffee grounds to remove impurities; The step of crushing the particles treated by classification; the first mixing step of mixing the binder or / and binder in the pulverized powder and stirring; the second mixing step of mixing purified water and stirring in the first mixing step a secondary mixing step; a step of putting the mixture generated through the above second mixing step into a mold, and performing compression molding; a drying step of drying the molded product; and a grinding step of grinding the molded product after drying.

[0015] More specifically, coffee grounds containing about 20% are recovered from co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com