Puffing tank with sealing door easy to open

A technology of sealing door and puffing tank, applied in the field of puffing tank with easy-to-open sealing door, can solve the problems of cumbersome opening and closing, waste of labor time, increase labor cost, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The expansion tank with an easy-to-open airtight door of the present invention will be further described in detail below with reference to the accompanying drawings.

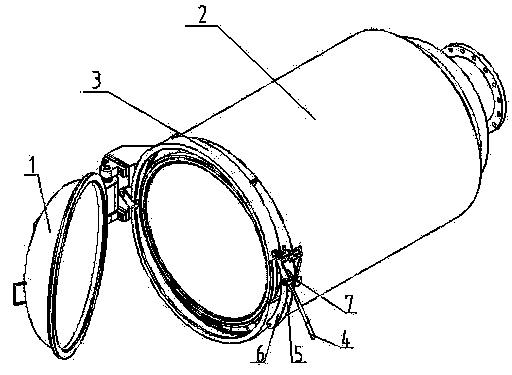

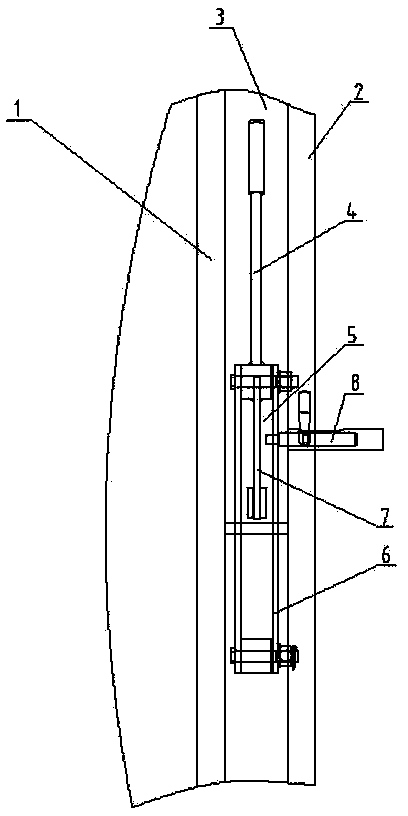

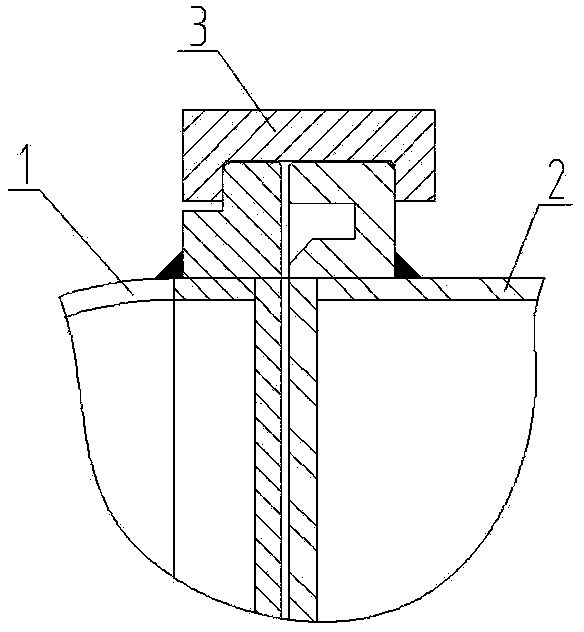

[0016] Such as Figure 1 to Figure 4 As shown, the expansion tank with an easy-to-open airtight door of the present invention includes a door panel 1 and a tank body 2, the door panel 1 is circular, and the tank body 2 is cylindrical. The outer periphery of the door panel 1 corresponding to the side of the tank body 2 is processed with a flange, and the corresponding end of the tank body 2 is also processed with a flange, and a sealing ring is arranged between the door panel 1 and the tank body 2 . The door panel 1 and the tank body 2 are hinged together, so that the door panel 1 can be opened outward along the hinge point. An annular hoop 3 is installed on the outside of the flange of the tank body 2 . The hoop 3 includes two hoop 3 units, the two hoop 3 units have the same shape and are semicircular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com