Online recycling device for leftovers of cast film

A recycling device and casting film technology, which is applied in the field of online recycling device for cast film trimmings, can solve problems such as poor feeding and unstable film thickness, and achieve stable extrusion volume, stable product thickness, and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

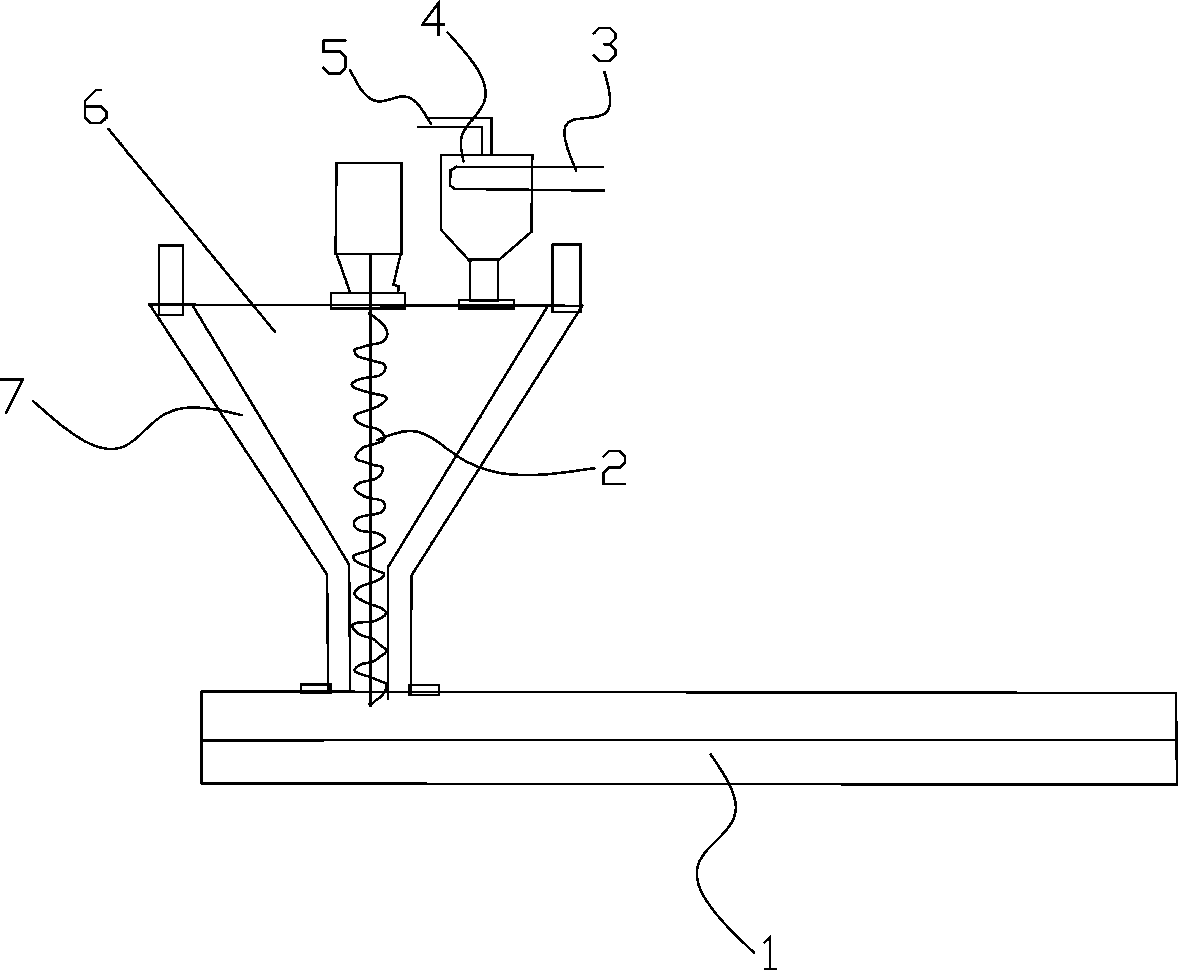

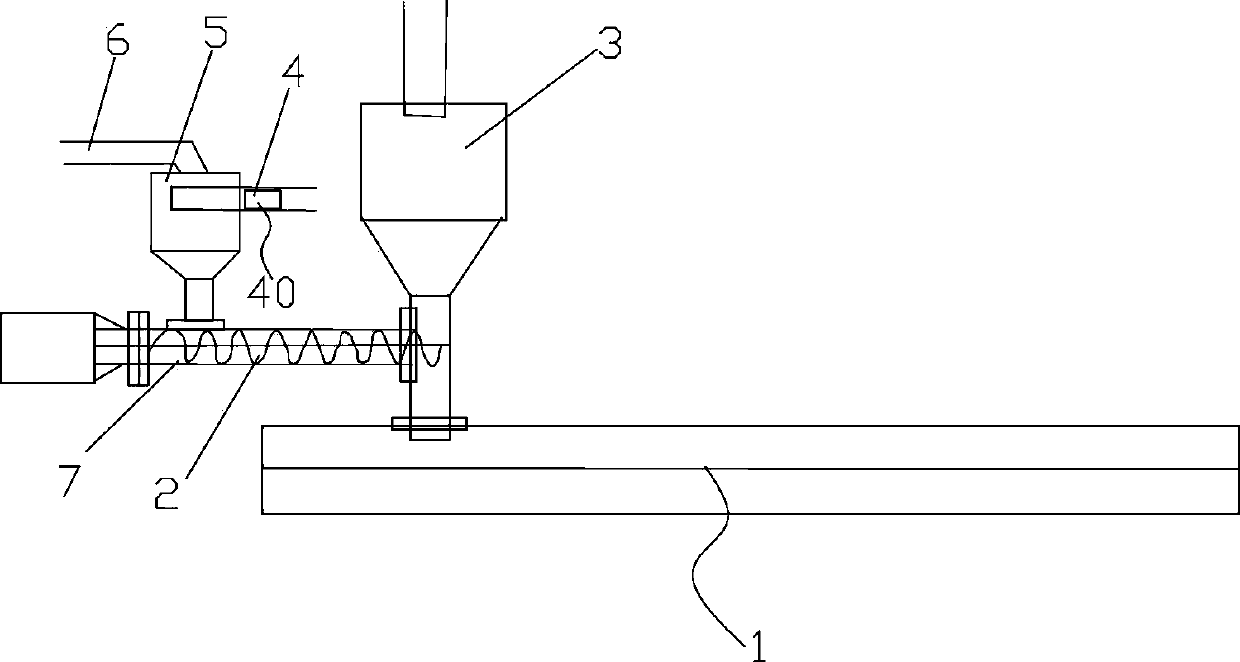

[0010] Below the present invention is described in further detail, see figure 2 , casting film edge material on-line recycling device, comprising a new material funnel 3 connected with the extruder, an old material conveying pipe 7 is horizontally arranged on one side of the new material funnel 3, and the old material conveying pipe 7 A conveying screw 2 for conveying powder is arranged in the middle, and a used material conveying funnel 5 is connected above the used material conveying pipe 7, and a used material conveying pipeline 4 is connected to one side of the used material conveying funnel 5.

[0011] A cyclone separator 40 is provided at the end connecting the old material conveying pipeline 4 and the used material conveying funnel 5 , and an outlet pipe 6 of the cyclone separator is arranged at the old material conveying funnel 5 .

[0012] The powder material freely falls into the conveying screw 2 of the used material conveying funnel 5 in the cyclone separator 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com