Aroma enhancement tobacco stem microwave expansion system and method

A technology of microwave expansion and tobacco stems, which is applied in tobacco, tobacco processing, application, etc., can solve the problems of overheating or ignition of tobacco stems, dry smell of tobacco stems, burnt out of drum materials, etc., to reduce production costs and remove tobacco stems The effect of impurities and high filling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

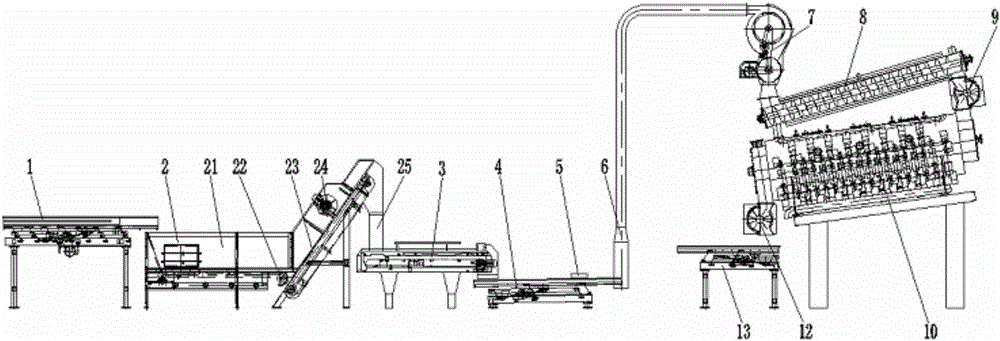

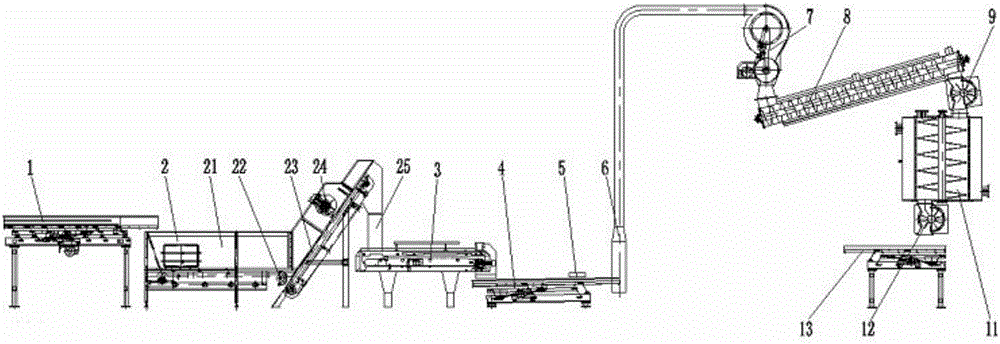

[0052] The method for flavoring tobacco stems based on the aroma-increasing tobacco stem microwave expansion system provided by the present invention, goes through the following steps:

[0053] A, the tobacco stems are sent into the screening machine 1, and after screening to remove impurities, they are sent to the buffer storehouse 21 of the first conveyor 2 for buffering;

[0054] B. Send the tobacco stems in the buffer bin 21 of the first conveyor 2 to the metering conveying scale 3 through the inclined conveyor belt 23, the rake roller 24, and the feeding pipe 25 at a flow rate of 500kg / h, and then meter and convey to the second The conveyor 4 absorbs impurities such as metal iron through the powerful iron remover 5;

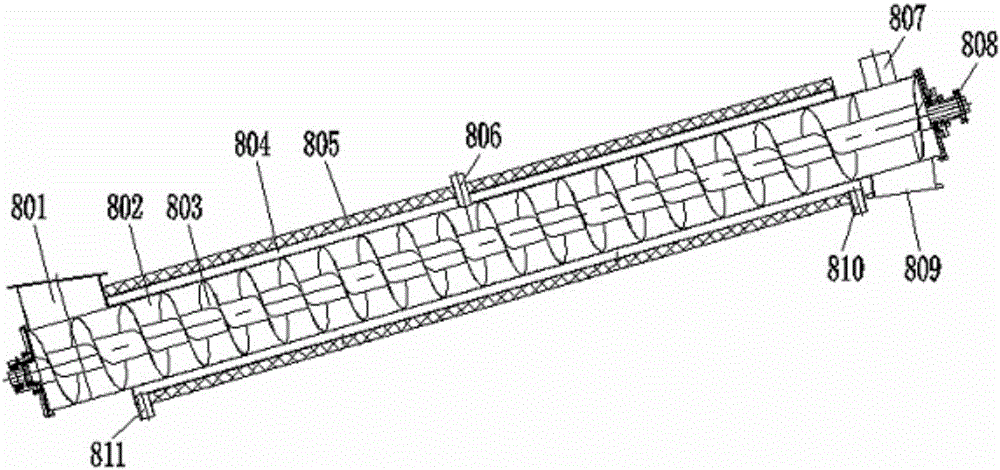

[0055] C. The tobacco stems in step B are sent to the temperature-increasing and humidifying conveyor 8 through the air delivery pipeline 6 and the gas-solid separation and feeding device 7, and at the same time, steam is sent to the temperature-increasing a...

Embodiment 2

[0060] The method for flavoring tobacco stems based on the aroma-increasing tobacco stem microwave expansion system provided by the present invention, goes through the following steps:

[0061] A, the tobacco stems are sent into the screening machine 1, and after screening to remove impurities, they are sent to the buffer storehouse 21 of the first conveyor 2 for buffering;

[0062] B. Send the tobacco stems in the buffer bin 21 of the first conveyor 2 to the metering conveying scale 3 through the inclined conveyor belt 23, the rake roller 24, and the feeding pipe 25 at a flow rate of 2000kg / h, and then meter and convey to the second The conveyor 4 absorbs impurities such as metal iron through the powerful iron remover 5;

[0063] C. The tobacco stems in step B are sent to the temperature-increasing and humidifying conveyor 8 through the air delivery pipeline 6 and the gas-solid separation and feeding device 7, and at the same time, steam is sent to the temperature-increasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com