Lift fan system for air cushion ship model

A fan system and hovercraft technology, applied in ship parts, ship construction, ships, etc., can solve the problems of hovercraft impact, low fan pressure, heavy weight, etc., achieve low cost, improve work performance, and increase pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

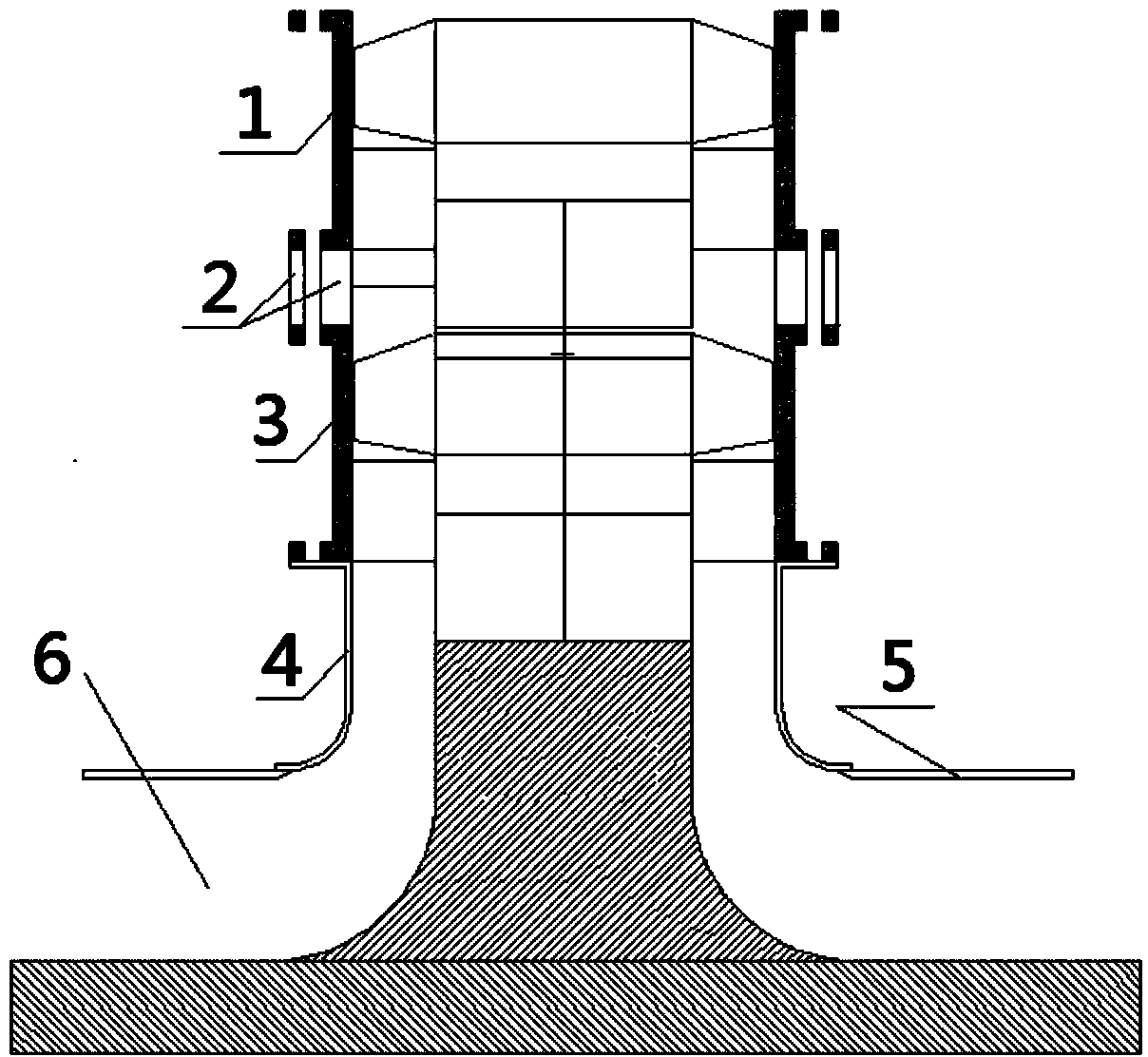

[0018] Such as figure 1 As shown, there is an air channel 6 in the hovercraft model body, and a pad-lift fan unit is provided above the hovercraft model body. The pad-lift fan unit is composed of two fans connected in series. fan. The two fans are set up and down, and the outer casing 1 of the upper fan and the outer casing 2 of the lower fan are connected and fixed through the ring sleeve 3 . The ring sleeve 3 adopts an aluminum ring sleeve, and the inner diameter of the ring sleeve 3 is consistent with the inner diameter of the blower fan. Changing the height of the ring sleeve according to needs can adjust the height of the center of gravity of the fan unit and the interval between the two blowers.

[0019] The air outlet of the lower blower fan connects the sleeve 4, and the bottom of the sleeve 4 joins with the hovercraft model body 5 (the upper deck of the hovercraft model), and the sleeve communicates with the air passage 6 in the hovercraft model body. The sleeve 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com