Treatment device and treatment method of biological diesel oil waste water

A biodiesel and wastewater treatment technology, applied in the direction of adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as easy scaling, high cost, difficult separation, etc., to achieve Significant adsorption effect, good reuse effect, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

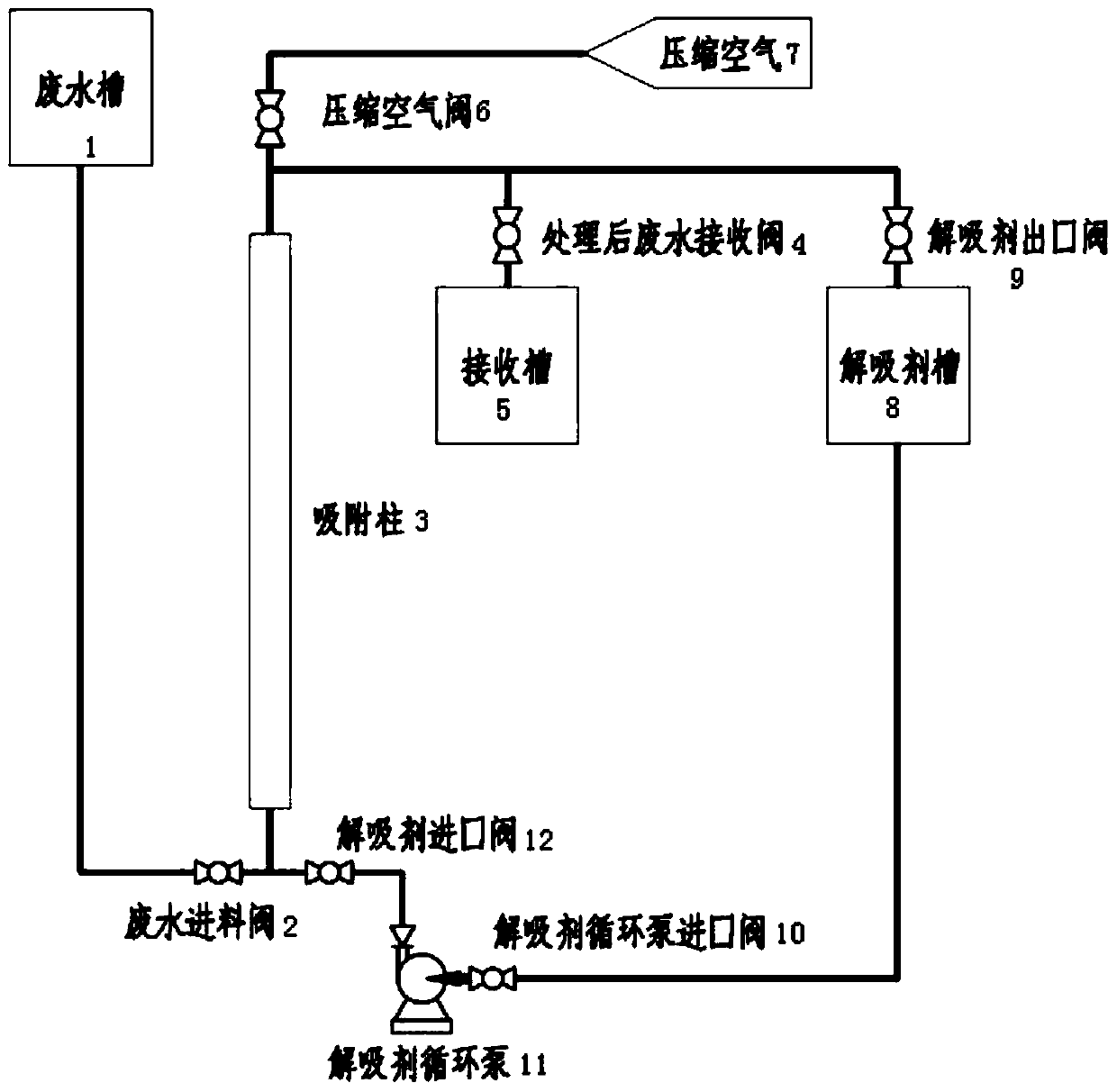

[0017] See figure 1 , Biodiesel wastewater treatment equipment, including wastewater tank 1, wastewater feed valve 2, adsorption column 3, treated wastewater receiving valve 4, receiving tank 5, compressed air valve 6, compressed air 7, desorbent tank 8, desorbent outlet Valve 9, desorbent circulation pump inlet valve 10, desorbent circulation pump 11, desorbent inlet valve 12 and pipeline 13; waste water feed valve 2 is set on the pipeline where the outlet of waste water tank 1 communicates with the lower end of adsorption column 3 13; the treated wastewater receiving valve 4 is set on the pipeline 13 where the high end of the adsorption column 3 communicates with the inlet of the receiving tank 5; the compressed air valve 6 is set at the outlet of the compressed air 7 and the high end of the adsorption column 3 On the pipeline 13; the desorbent outlet valve 9 is arranged on the pipeline 13 where the outlet of the desorbent tank 8 communicates with the high end of the adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com