Method for preparing beta2 microglobulin crude product

A technology of β2-microglobulin and crude products is applied in the field of preparing β2-microglobulin, which can solve the problems of unsuitable industrial production, limited scale of preparation and high preparation cost, and achieve comprehensive utilization, reduce difficulty and prevent environmental problems. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

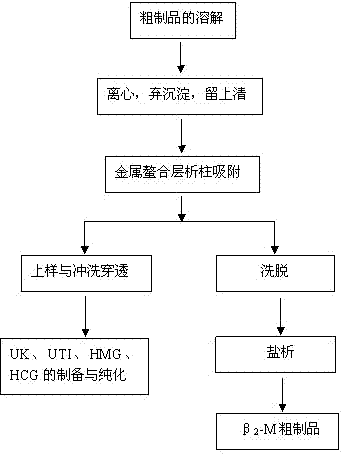

Method used

Image

Examples

Embodiment 1

[0034] Take 100g UK crude product, add 1000ml of 0.01MTris-HCl buffer solution (pH7.6) to dissolve, centrifuge at 4000rpm for 10min, take the supernatant, filter it with a 0.45μm filter membrane, adjust the pH of the filtrate to 7.6, and conductance 1.06mS / cm, The well-balanced metal ion on the surface is Cu 2+ Metal chelate chromatography column (Chelating sepharose FF); and then the balance solution (0.3M NH 4 Cl, 0.01M Tris-HCl, pH 7.6) to wash the metal chelate chromatography column, collect the loading and washing breakthroughs for the preparation and purification of UK; use 0.07M glycine, 0.01MTris-HCl , pH8.0 to wash the column; use 0.5M glycine, 0.01M Tris-HCl, pH8.0 elution solution to elute the column; collect the elution solution.

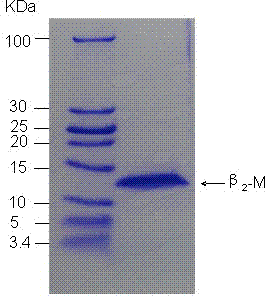

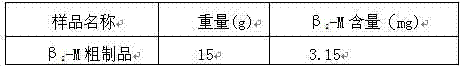

[0035] Add ammonium sulfate powder to the collected eluent to saturation, stir while adding, let it stand for 4 hours, add 10 g of diatoms to collect by centrifugation and dry the precipitate to obtain β 2 -M crude product 16 g.

[00...

Embodiment 2

[0040] Take 100g of crude UTI, add 1000ml of 0.1M phosphate buffer (pH6.0) to dissolve, filter through diatomaceous earth plate and frame, and then filter with 0.45μm filter membrane. Adjust the pH of the filtrate to 6.0, the conductance is 0.2mS / cm, and the balanced metal ion is Zn 2+ The metal chelation chromatography column (Chelating sepharose FF); then use the equilibrium solution (equilibrium solution formula: 0.1MNH 4 Cl, 0.1M phosphate, pH6.0) to wash the metal chelate chromatography column, collect the sample breakthrough and wash the breakthrough for the preparation and purification of UTI; use 0.05M glycine, 0.1M phosphate, Wash the column with pH 7.0 flushing solution; elute the column with an eluting solution containing 0.1M glycine, 0.02M Tris-HCl, pH 7.0; collect the eluting solution.

[0041] Add ammonium sulfate powder to the collected eluted solution to saturation, stir while adding, let it stand for 4 hours, add 10 g of diatomaceous earth to collect by cent...

Embodiment 3

[0046] Take 100g of crude HMG, add 1000ml of 0.05M phosphate buffer (pH7.0) to dissolve, centrifuge at 4000rpm for 10min, take the supernatant, and filter it with a 0.45μm filter membrane to obtain the filtrate. Adjust the pH of the filtrate to 7.0, the conductance is 0.78mS / cm, and the balanced metal ion is Cu 2+ The metal chelate chromatography column (Chelating sepharose FF); then use the equilibrium solution (0.2MNH 4 Cl, 0.05M Phosphate, pH7.0) to wash the metal chelate chromatography column, collect the sample penetration and washing breakthrough, for the preparation and purification of HMG; use 0.1M glycine, 0.05M phosphate, Wash the column at pH 7.6; elute the column with an elution solution containing 0.38M glycine, 0.05M Tris-HCl, pH 8.3; collect the elution solution.

[0047] Add ammonium sulfate powder to the collected eluted solution to saturation, stir while adding, let it stand for 4 hours, add 10 g of diatomaceous earth to collect by centrifugation and dry the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com