Device for adjusting breadth of weaving machine comber boards

A technology of width adjustment and eye board, which is applied in the fields of textile, jacquard, textile and paper making, can solve the problems of time-consuming, troublesome operation and low work efficiency, and achieve good reliability, convenient adjustment and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

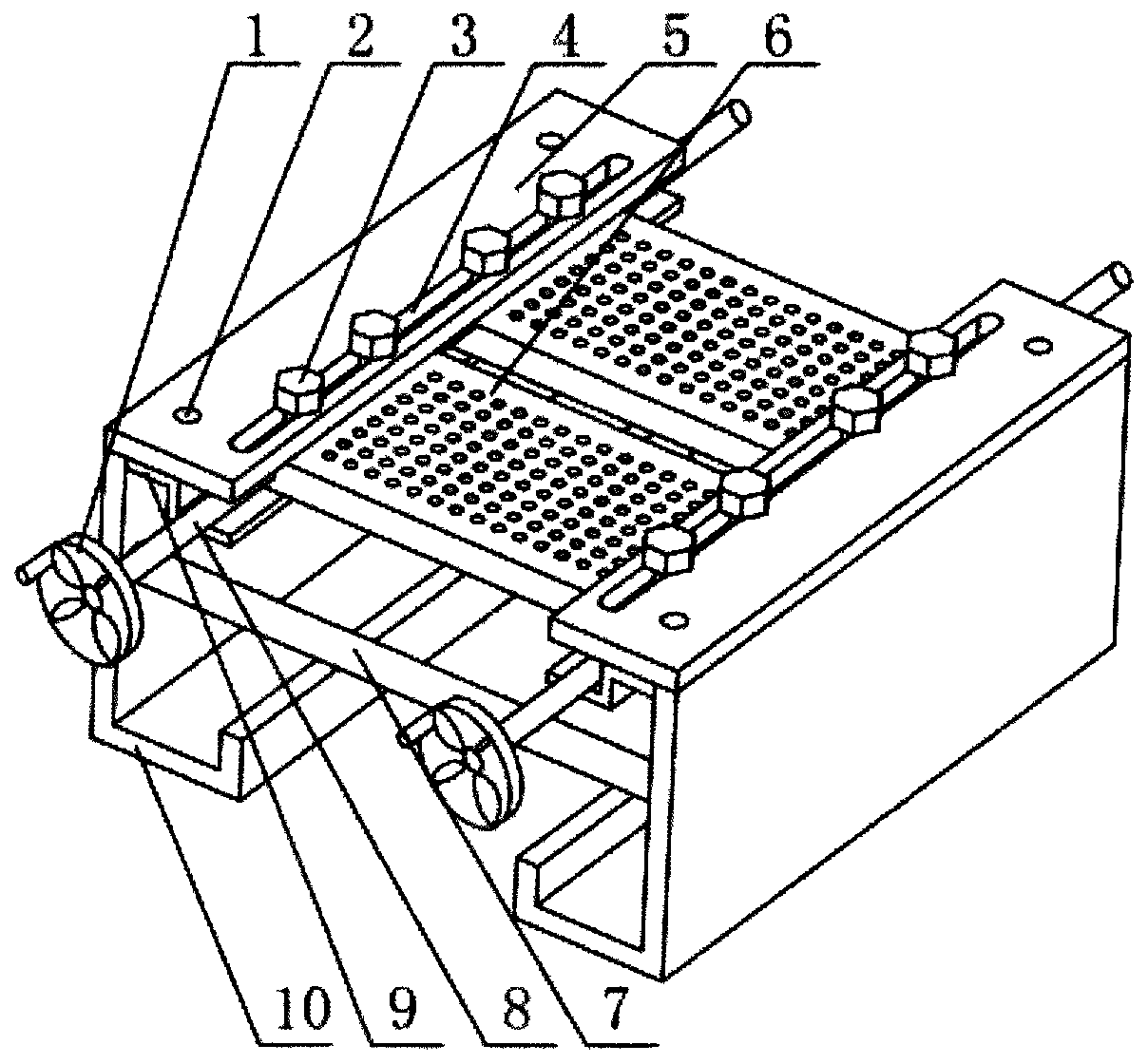

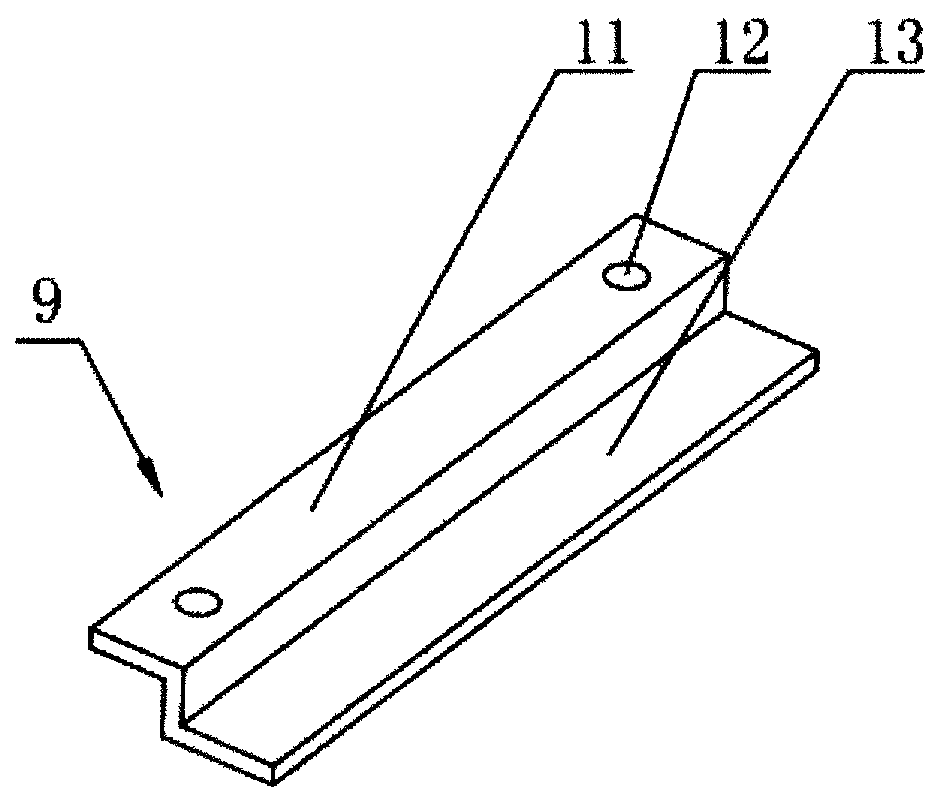

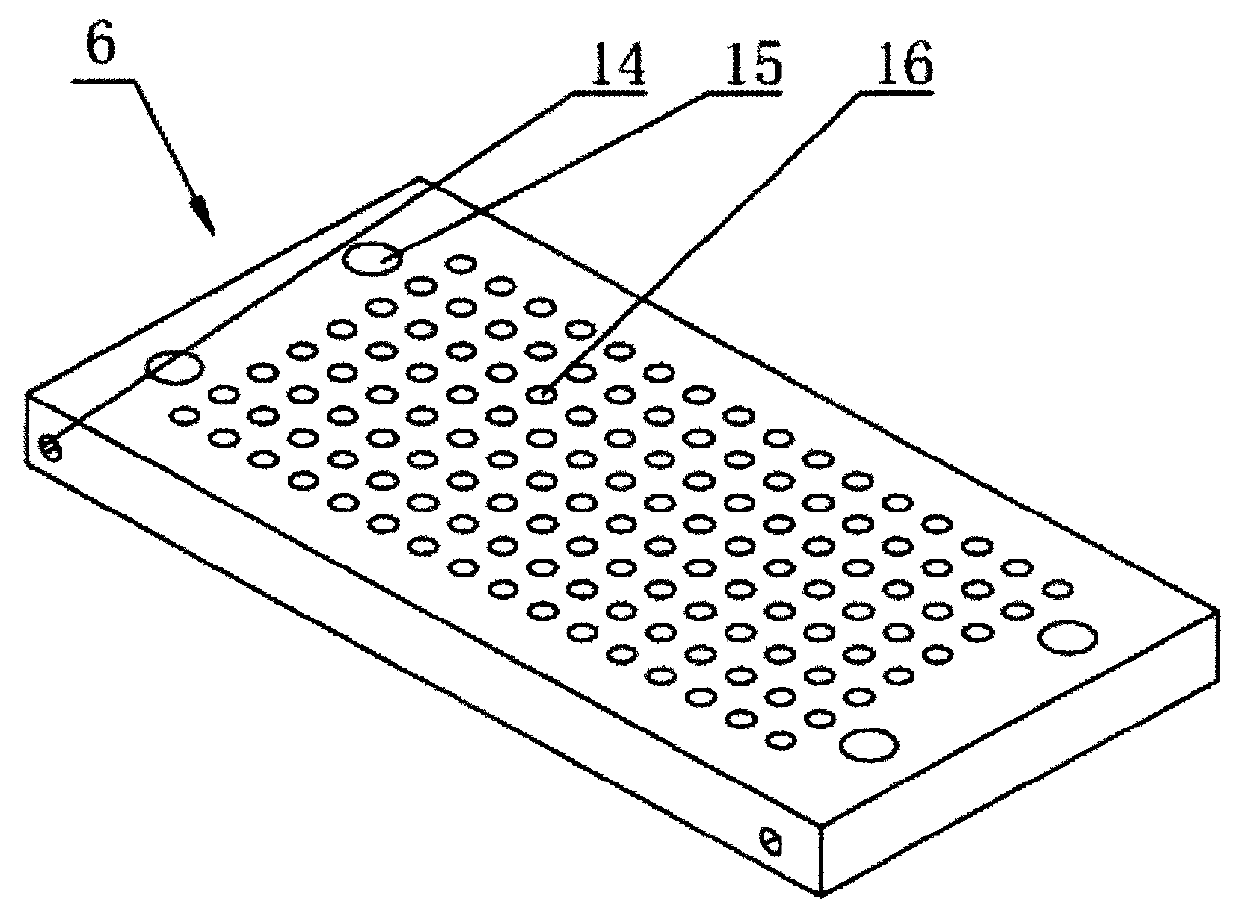

[0021] Such as figure 1 As shown, the air-jet loom width adjusting device of the present embodiment includes the eye plate frame 10 installed at intervals, the top of the eye plate frame 10 is respectively equipped with a Z-shaped plate 9, and the top of the Z-shaped plate 9 is installed by a fastener. Panel 5, a notch is formed between the panel 5 and the Z-shaped plate 9, and a plurality of parallel mesh plates 6 arranged at intervals are installed in the notch, and the two ends of the mesh plate 6 are fixed in the notch by fasteners, and the mesh plate 6 There are threaded holes 14 respectively at the two ends of the threaded holes 14, and a rotating shaft 8 is passed through the threaded holes 14. External threads are provided on the outer circumference of the rotating shaft 8, and the head of the rotating shaft 8 is equipped with a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com