S-shaped wind wheel

A wind wheel and anemometer technology, which is applied to wind turbines, wind turbine combinations, wind turbine control, etc., can solve the problems of reduced fan stiffness, troublesome support rods, low success rate, etc., and can compensate for the deviation of hole positions. , The effect of reducing installation cost and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

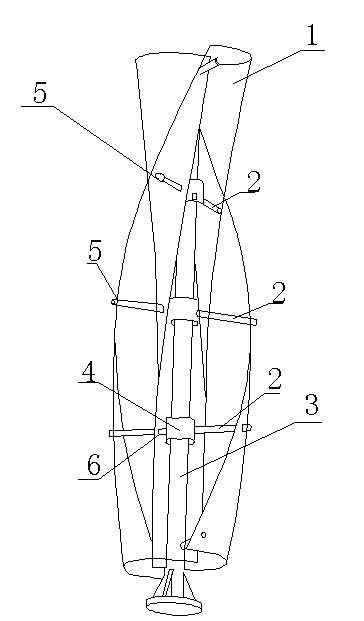

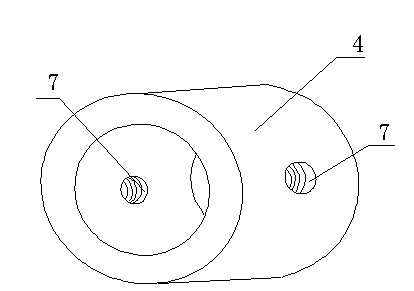

[0019] Such as figure 1 , figure 2 As shown, an S-shaped wind wheel includes fan blades 1, studs 2, a central shaft sleeve 4, a central shaft 3 and a generator, the central shaft 3 is fixed on the generator, and the central shaft sleeve 4 is fixed on the central shaft 3 Above, the central shaft sleeve 4 is provided with an opening 7, the opening 7 is provided with an internal thread, one end of the stud 2 is arranged on the external thread corresponding to the internal thread, and one end of the stud 2 is fixed on the central shaft sleeve 4 through threads. The other end of the stud 2 is fixedly connected with the fan blade 1 .

[0020] Wherein, the top of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com