balance valve

A technology of balance valve and valve body, which is applied in the field of hydraulic valves, can solve the problems that the balance valve opening cannot be adjusted well, affects the scope of application, and is prone to damage, etc., so as to improve flexibility and application scope, reduce jitter, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

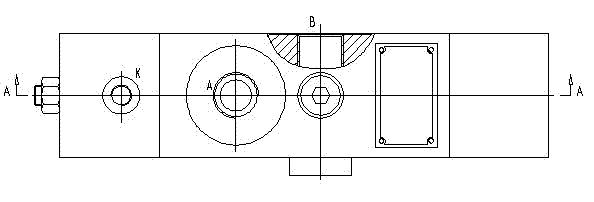

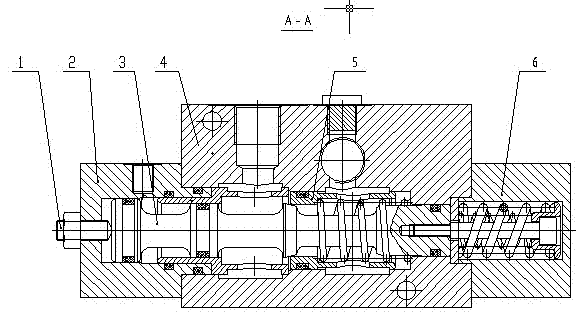

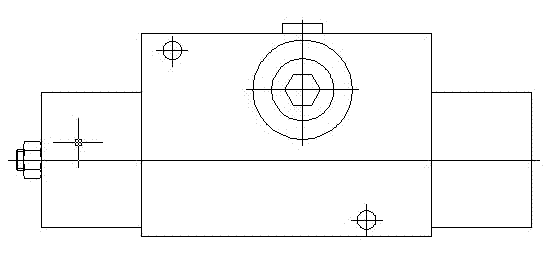

[0015] The present invention includes a valve body 4 and left cover 2 and right cover 6 arranged on both sides of the valve body. The valve body 4 is provided with two oil ports A and B, and the left cover 2 is provided with a control oil port K; There is a valve stem 3 that can move along the inner cavity of the valve body 4. There is a channel between the oil ports A and B. The inner cavity of the valve body 4 is provided with a valve seat 5 that cooperates with the valve stem 3 to open or cooperate with the channel. .

[0016] In the present invention, the pressure difference direction of the control oil port K acting on the valve rod 3 is consistent with the oil return direction.

[0017] The left cover 2 is provided with an adjusting screw 1 , and the adjusting screw 1 extends to the inner cavity of the valve body 4 and contacts with the valve stem 3 .

[0018] The working process of the present invention is: when the oil is fed from the A oil port to the B oil port, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com