Split type exhaust hood

A range hood and split-type technology, which is applied in the field of split-type range hoods, can solve the problems of low reliability and high use noise, and achieve the effects of smooth ventilation, reduced use noise, and smooth suction of range fumes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

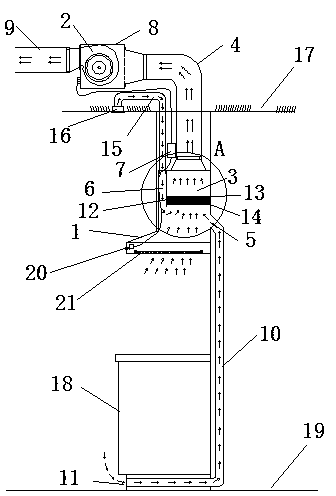

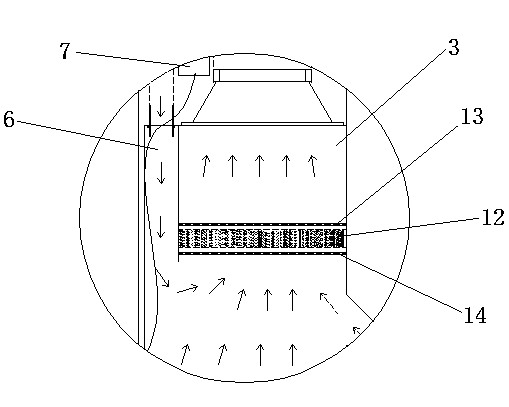

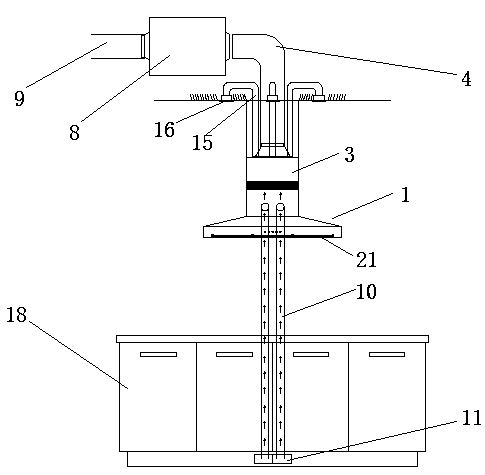

[0024] like figure 1 and image 3 As shown, a split-type range hood according to the present invention includes a fan 2, a fan power control box 7, a smoke exhaust pipe 4, a public flue 9 and a range hood body 1, and the public flue 9 is a new residential building. The designed flue, fan power control box 7 is used to control the use of fan 2. The range hood body 1 is provided with a switch panel 20 and a main air chamber 3, and the exhaust pipe 4 is connected and installed with the main air chamber 3, and the main air chamber 3 is a part where a fan is installed in the prior art. In the prior art, the blower fan is installed in the main air chamber 3, and then the oil fume is sucked into the main air chamber 3 by the blower fan and then sent out to the smoke exhaust pipe 4 to be discharged outside. The blower fan 2 is installed between the public flue 9 and the smoke exhaust pipe 4. In the present invention, the blower fan 2 is moved out of the main air chamber 3 and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com