Blade rotating speed measuring device

A technology for measuring device and blade speed, which is applied in the direction of measuring device, fluid speed measurement, speed/acceleration/impact measurement, etc. It can solve problems such as difficult guarantee of strength, distortion of speed measurement, and influence on measurement accuracy, so as to achieve fast installation and reduce The effect of weight and rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

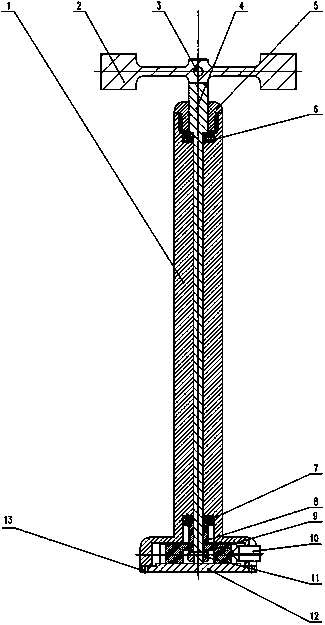

[0011] Such as figure 1 As shown, the inside of the stepped sleeve 1 is a through hole with a diameter of 5mm and a length of 192.5mm, and the two ends are respectively stepped holes with different diameters, wherein one end of the stepped sleeve 1 is provided with a diameter of 16mm, a height of 5mm and M19X1.5mm , a stepped hole with a height of 10mm, and the other end is provided with a stepped hole with a diameter of 16mm, a height of 14mm, a diameter of 48mm, and a height of 16mm; axis 4 is set as a stepped axis with a diameter of 10mm, a length of 38mm, a diameter of 5mm, and a length of 222mm; axis 4 Through the through hole of the step sleeve 1, the first bearing bearing 6 is installed on the shaft with a diameter of 5mm of the shaft 4, and then is set in a hole with a diameter of 16mm and a height of 5mm, wherein one side of the first bearing 6 is tightly Attach the stepped surface of the shaft 4, the nut 5 cooperates with the M19X1.5mm hole on the stepped sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com