A sealed transfer connector for ultra-low temperature environment and its manufacturing method

A transfer connector and manufacturing method technology, applied in the assembly/disassembly of contacts, base/housing, etc., can solve problems such as performance failure, low operating temperature of electrical connectors, safety accidents, etc., and achieve good sealing effect and expansion The effect of wide low temperature service limit and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

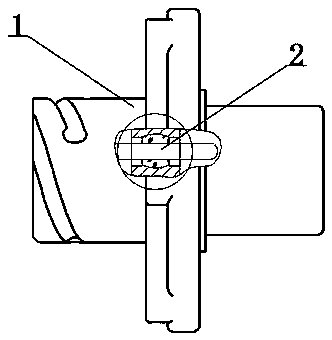

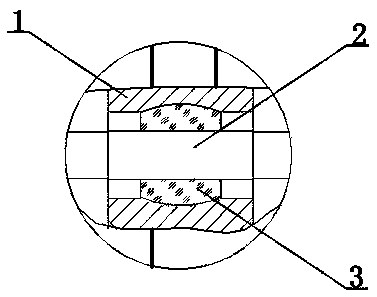

[0019] Such as figure 1 , 2 As shown, a sealed transfer connector for ultra-low temperature environment, including a metal shell 1, the metal shell 1 has a plurality of through holes arranged in the axial direction, each through hole is pierced with a pin 2, a glass sealing body is integrally sintered between the metal shell 1 and the pin 2, the protruding end of the pin 2 of the metal shell 1 is provided with a marked hole position, a sealing rubber ring and a numbering plate, and the metal The other end of the shell 1 is provided with an insulator part, and the insulator part is fixed in the inner cavity of the metal shell 1 by a circlip. The insulator part is provided with a crimping jack, and one end of the crimping jack is connected to the pin 2, and Connect the other end to the cable. The glass sealing body is a glass tube 3, and the glass tube 3 is sleeved outside the pin 2, and the outer wall of the glass tube 3 and the inner wall of the metal shell 1 and between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com