Filter tip, cigarette and filter tip preparation method

A technology for filter tips and cigarettes, which is applied in the fields of tobacco, smoke oil filter elements, and cigar manufacturing, etc. It can solve the problems of low utilization rate of flavors, odors in the production line, residual flavors, etc., and achieve less filling, improved usability, and improved adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

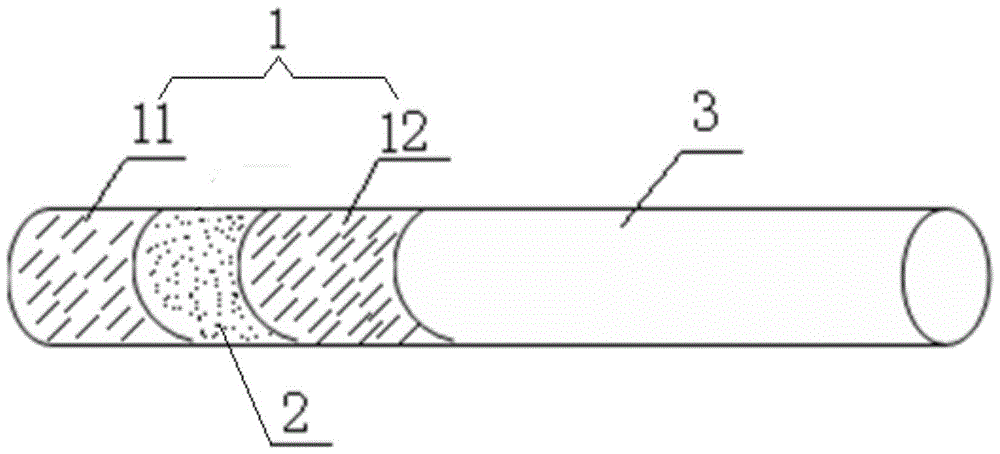

[0036] Such as figure 1 As shown, the filter tip provided by the embodiment of the present invention includes a filter element and tipping paper wrapping the filter element, wherein: the filter element includes a tow filter stick 1 and a filler 2 emitting a predetermined fragrance, and the filler 2 is expanded shredded tobacco with essence added . The essence is preferably mint flavor essence. And the tow filter rod 1 and the filler 2 are connected together.

[0037] The present invention adds expanded shredded tobacco filler 2 emitting a predetermined fragrance (for example: mint flavor) to the filter tip, which improves the usability of adding fragrance, because the expanded shredded tobacco is treated to improve the absorption of mint essence. The amount of filler 2 is small, the amount of shredded tobacco is large, and the essence is easy to be fully utilized, reducing the odor and residue in the production line.

[0038] As a preferred or optional embodiment, the tow f...

Embodiment 2

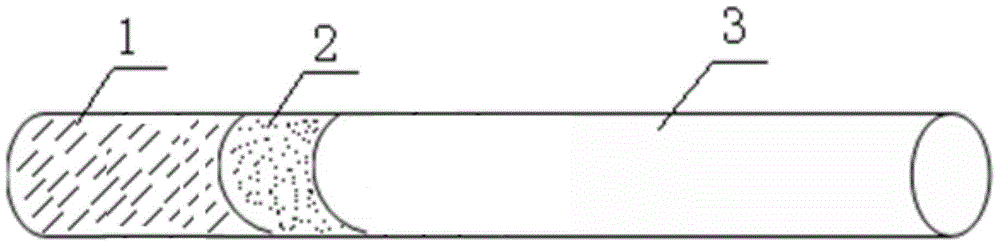

[0045] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, and its difference is:

[0046] In this embodiment, the filler 2 in the filter tip is connected to one end of the tow filter rod 1 . The filler 2 can be arranged between the cigarette branch 3 and the tow filter rod 1 along its axial direction.

[0047] Such as figure 1 and figure 2 As shown, the cigarette provided by the embodiment of the present invention includes a cigarette 3 and a filter provided by any technical solution of the present invention, and one end of the cigarette 3 is connected to one end of the filter.

[0048] Because the filter tip provided by the present invention has the above-mentioned advantages, the cigarette provided with the filter tip can also produce all the advantages that the filter tip can produce. Simultaneously, because the filter tip has the effect of lasting fragrance, so the fragrance of cigarette is also more lasting.

[0049] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com