Fitness equipment spring counterweight balancer

A technology of spring counterweight and fitness equipment, which is applied to gymnastics equipment, muscle training equipment, sports accessories, etc., can solve the problems of limited adjustment accuracy of fitness equipment, high cost of construction and transportation, and inconvenient conversion, and achieves the cost of construction and transportation. Inexpensive, conducive to promotion and popularization, the effect of simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

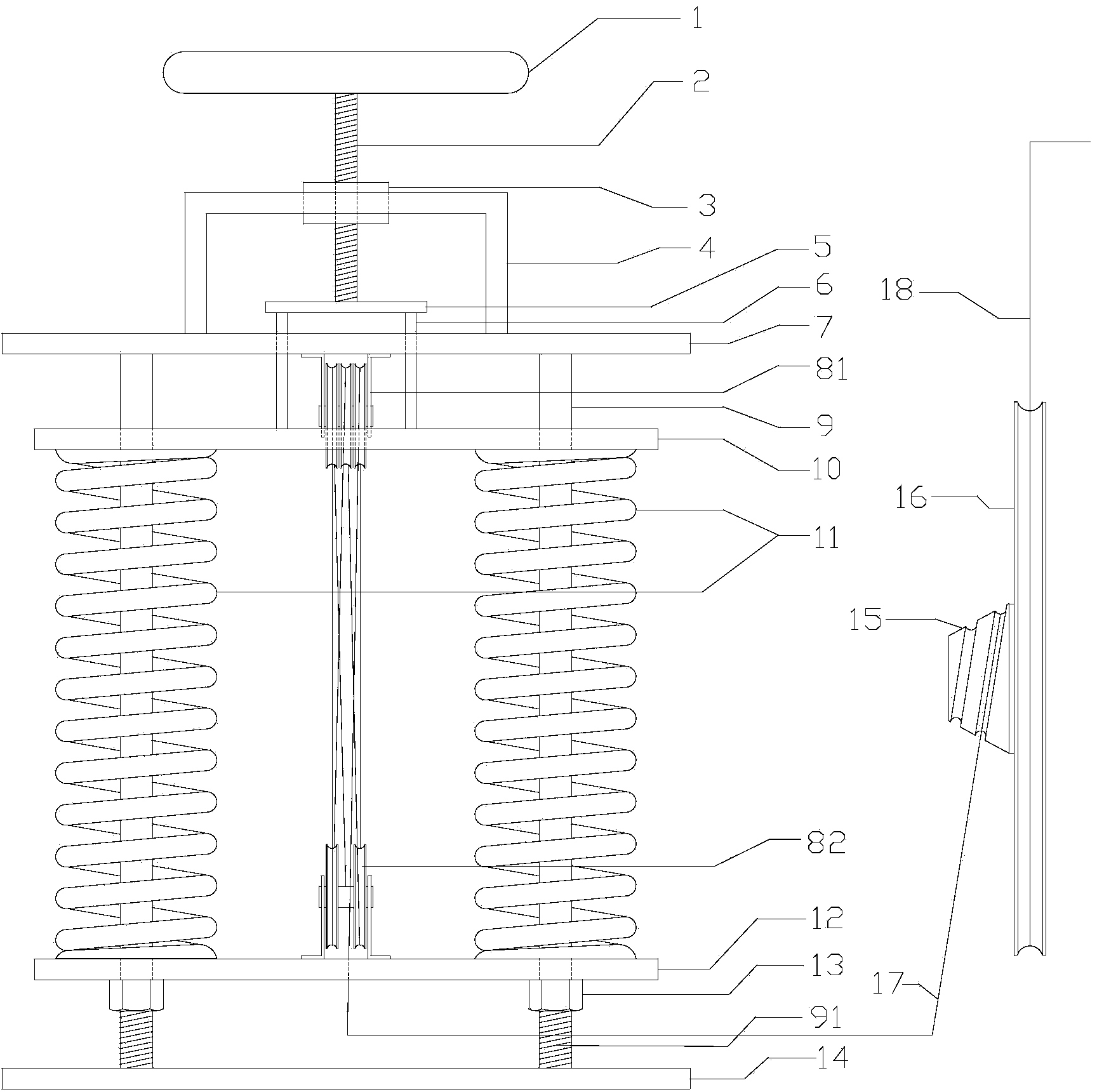

[0016] Such as figure 1 As shown, the embodiment of the present invention is provided with a hand wheel 1, a screw rod 2, a frame connecting nut 3, a gravity scale indicating device frame 4, a plane platen 5, a plane platen guide column 6, an upper frame beam 7, an upper pulley block 81, and a lower pulley block 82. Spring guide post 9, upper spring seat 10, two springs 11, lower spring seat 12, spring guide post connection nut 13, lower frame beam 14, vortex track 15, large round wheel 16, steel wire rope connecting pulley block and vortex track 17, big round wheel and body-building equipment connect wire rope 18.

[0017] The hand wheel 1 is fixed on the top of the screw rod 2, two springs 11 are arranged between the upper spring seat 10 and the lower spring seat 12, and the spring guide post 9 runs through the two springs 11 and the upper spring seat 10 and the lower spring seat 12. , the two ends of the spring guide post 9 are respectively connected with the upper frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com