Stirring knife assembly

A mixing knife and component technology, which is applied in the direction of mixer accessories, mixers, dissolving, etc., can solve the problems that the injection molding embedding process is not easy to control, cannot meet the needs of users, and cannot meet the needs of production, so as to avoid food residues and structure Simple and reasonable, easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

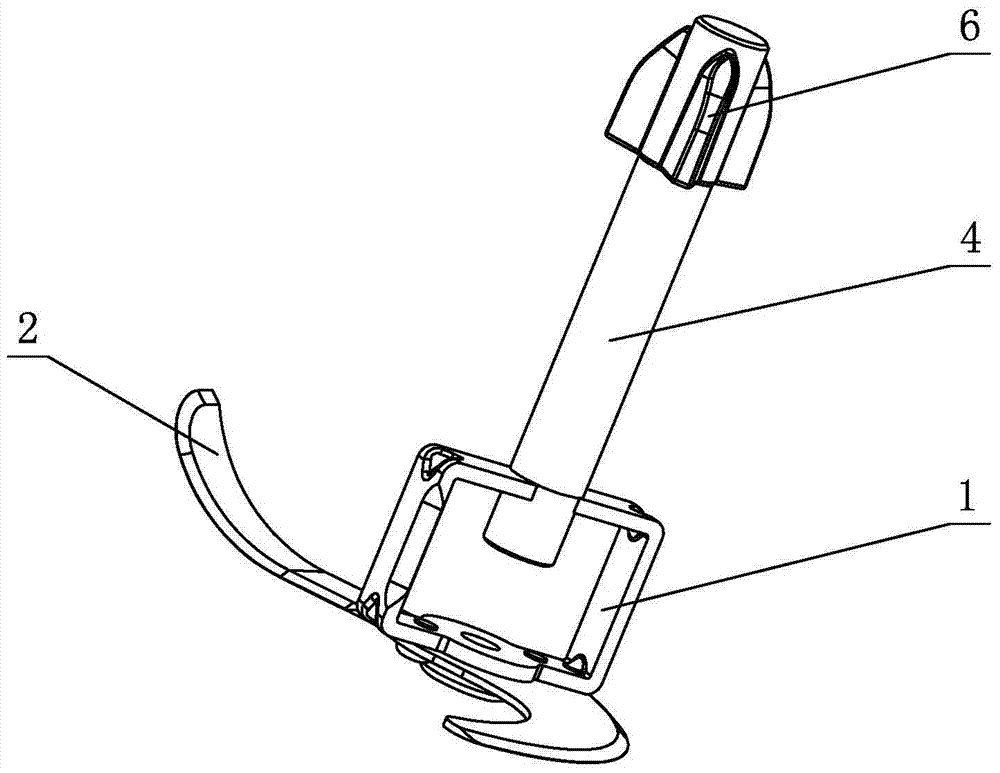

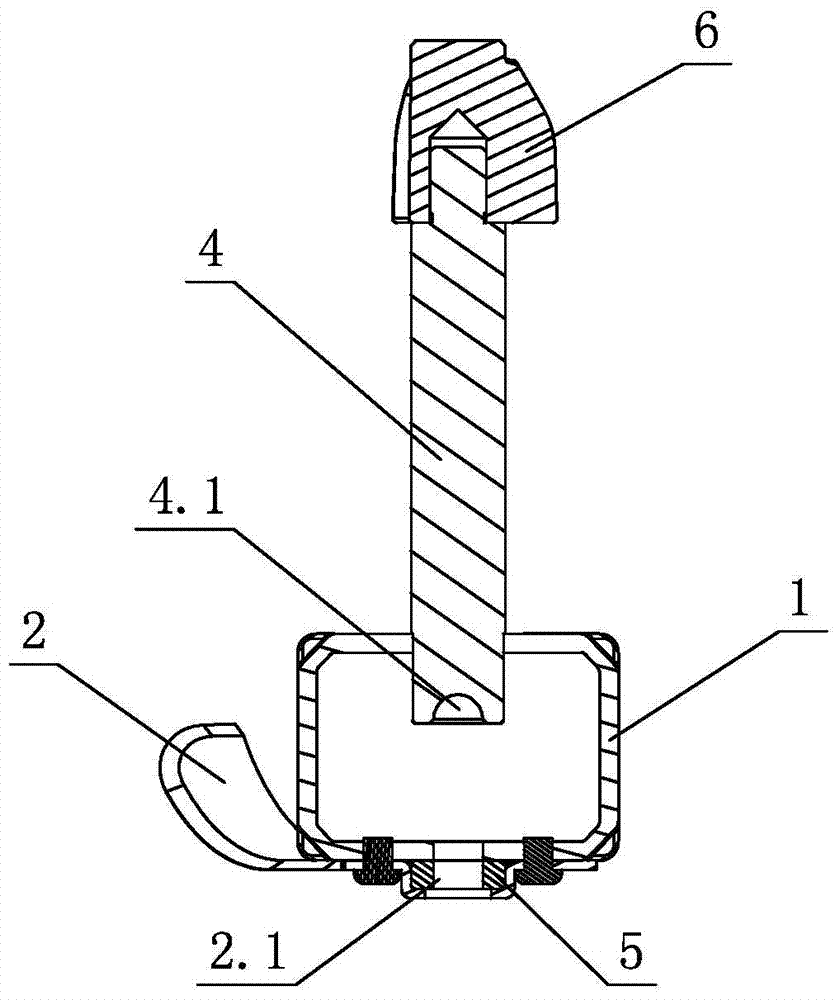

[0018] see figure 1 , figure 2 , the stirring knife assembly at least includes a knife support 1 and a stirring shaft 4, the knife support 1 is a frame structure, and fixedly provided with at least one blade thereon; the stirring shaft 4 is fixedly connected with the knife support 1.

[0019] The blade includes a first blade 2 fixedly arranged on the lower part of the knife support 1 . The knife support 1 has a square frame structure, a cavity 2.1 is provided between the first blade 2 and the knife support 1, and a damping sleeve 5 is provided in the cavity 2.1. The lower part of the stirring shaft 4 is provided with a recess 4.1, and the upper part is provided with a connector 6 to be connected with the power unit of the stirrer.

[0020] In order to improve stirring efficiency, a knife edge is also provided on the knife support 1 . The knife support 1, the stirring shaft 4 and the first blade 2 are arranged on the same axis line.

[0021] working principle:

[0022] Wh...

no. 2 example

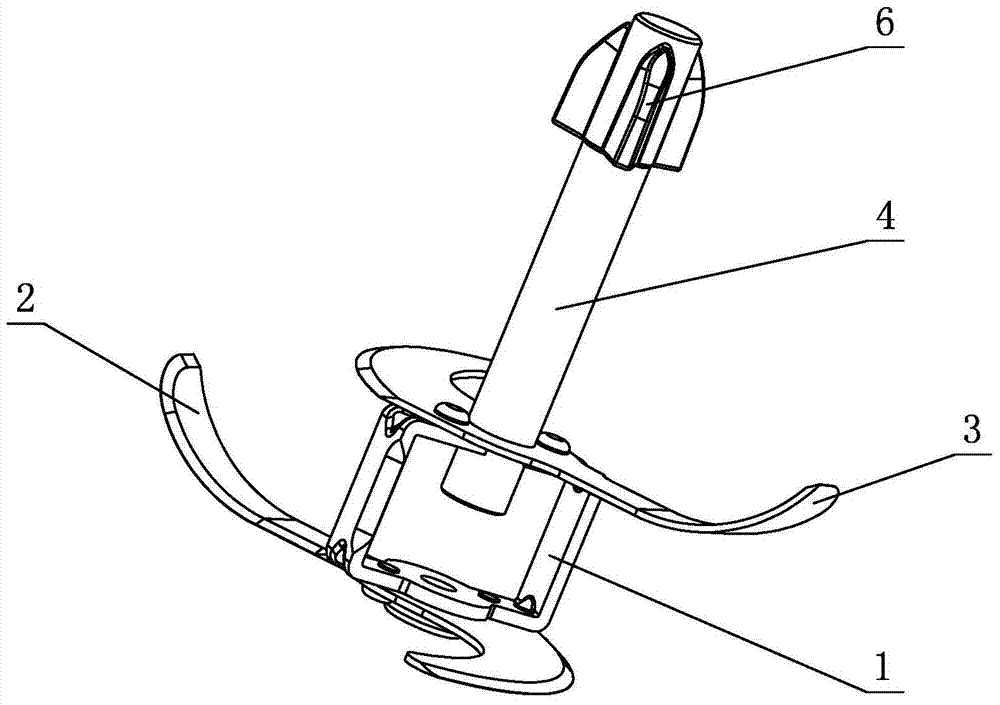

[0027] see image 3 , Figure 4 , this mixing knife assembly is different from the first embodiment in that: the blades include a first blade 2 and a second blade 3; wherein, the first blade 2 is fixedly arranged on the lower part of the knife bracket 1, and the second blade 3 is fixedly arranged On the top of the knife support 1.

[0028] Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0030] see Figure 5 , Figure 6 , this mixing knife assembly is different from the first embodiment in that: the blades include a first blade 2 and a second blade 3; wherein, the first blade 2 is fixedly arranged on the lower part of the knife bracket 1, and the second blade 3 is fixedly arranged on the stirring shaft 4.

[0031] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com