Steel mesh for printing printed circuit boards and printing machine

A technology for printed circuit boards and printing machines, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as high cost, unfavorable large-scale production, and inability to place printed circuit boards 6, and reduce The effect of saving production cost and printing machine cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

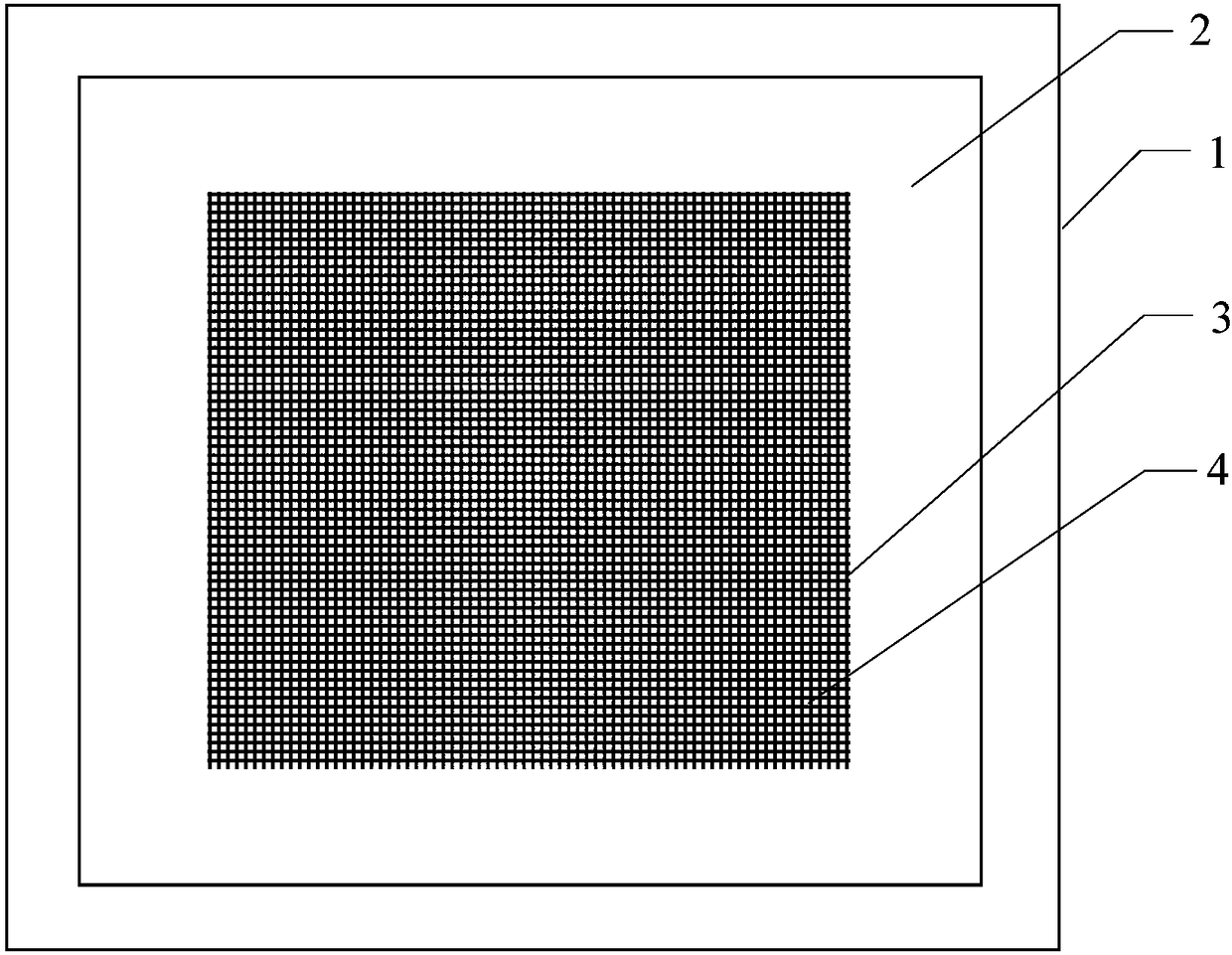

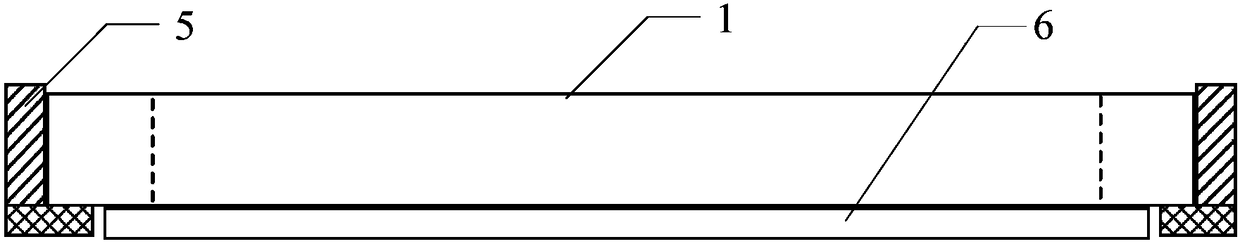

[0038] Such as Figure 7 As shown, the present invention is used for the stencil of printed circuit board, comprises screen frame 1 and omentum 2, and omentum 2 is positioned at the bottom surface of screen frame 1, and the middle part of omentum 2 is provided with opening area 3, and opening area 3 is provided with a plurality of mesh holes 4 for solder paste deposition, and the mesh frame is a rectangular frame, preferably a square frame. A group of opposite frames of the screen frame 1 are respectively provided with slots 11 (shown by dotted lines in the figure), and the two slots 11 are matched with the two steel screen brackets 5 of the printing machine respectively. When the screen frame 1 is supported between two stencil brackets 5 , the plane where the omentum 2 is located is not higher than the bottom surface of the two stencil brackets 5 . Because the omentum 2 is lower than the bottom surfaces of the two steel mesh brackets 5, or the bottom surfaces of the omentum ...

no. 2 example

[0040] Such as Figure 7 , Figure 8 and Figure 9 As shown, the stencil bracket 5 of the printing machine includes a limiting plate 51 and a supporting plate 52, the limiting plate 51 is arranged on the outside of the outer wall of the screen frame 1, and the limiting plates 51 of the two stencil brackets 5 are used to The stencil is confined within it. The supporting plate 52 is arranged vertically to the limiting plate 51, and is used to support the screen frame 1 of the steel mesh. Specifically, the steel mesh bracket 5 has an L-shaped cross section, its long side is a limiting plate 51 , and its short side is a supporting plate 52 . In this embodiment, the slot 11 is located on the bottom of a group of opposite frames, and the slot 11 forms a step on the bottom of the frame, so that the interface of the stencil in the direction where the printed circuit board 6 enters has an inverted convex shape. The supporting plate 52 is located in the slot 11, that is, in the gap of...

no. 3 example

[0042] Such as Figure 7 , Figure 8 and Figure 9 As shown, the stencil bracket 5 of the printing machine includes a limiting plate 51 and a supporting plate 52, the limiting plate 51 is arranged on the outside of the outer wall of the screen frame 1, and the limiting plates 51 of the two stencil brackets 5 are used to The stencil is confined within it. The supporting plate 52 is arranged vertically to the limiting plate 51, and is used to support the screen frame 1 of the steel mesh. Specifically, the steel mesh bracket 5 has an L-shaped cross section, its long side is a limiting plate 51 , and its short side is a supporting plate 52 . In this embodiment, the slot 11 is located on the bottom of a group of opposite frames, and the slot 11 forms a step on the bottom of the frame, so that the interface of the stencil in the direction where the printed circuit board 6 enters has an inverted convex shape. The supporting plate 52 is located in the slot 11 , that is, in the not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com