Method for producing reflection sheet lampshade

A manufacturing method and technology of reflective sheets, which are applied to household components, household appliances, and other household appliances, etc., can solve problems such as complicated manufacturing process, difficult control of reflective layer coating quality, and difficulty in developing molds for long workpieces, etc. Achieve the effect of unlimited size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

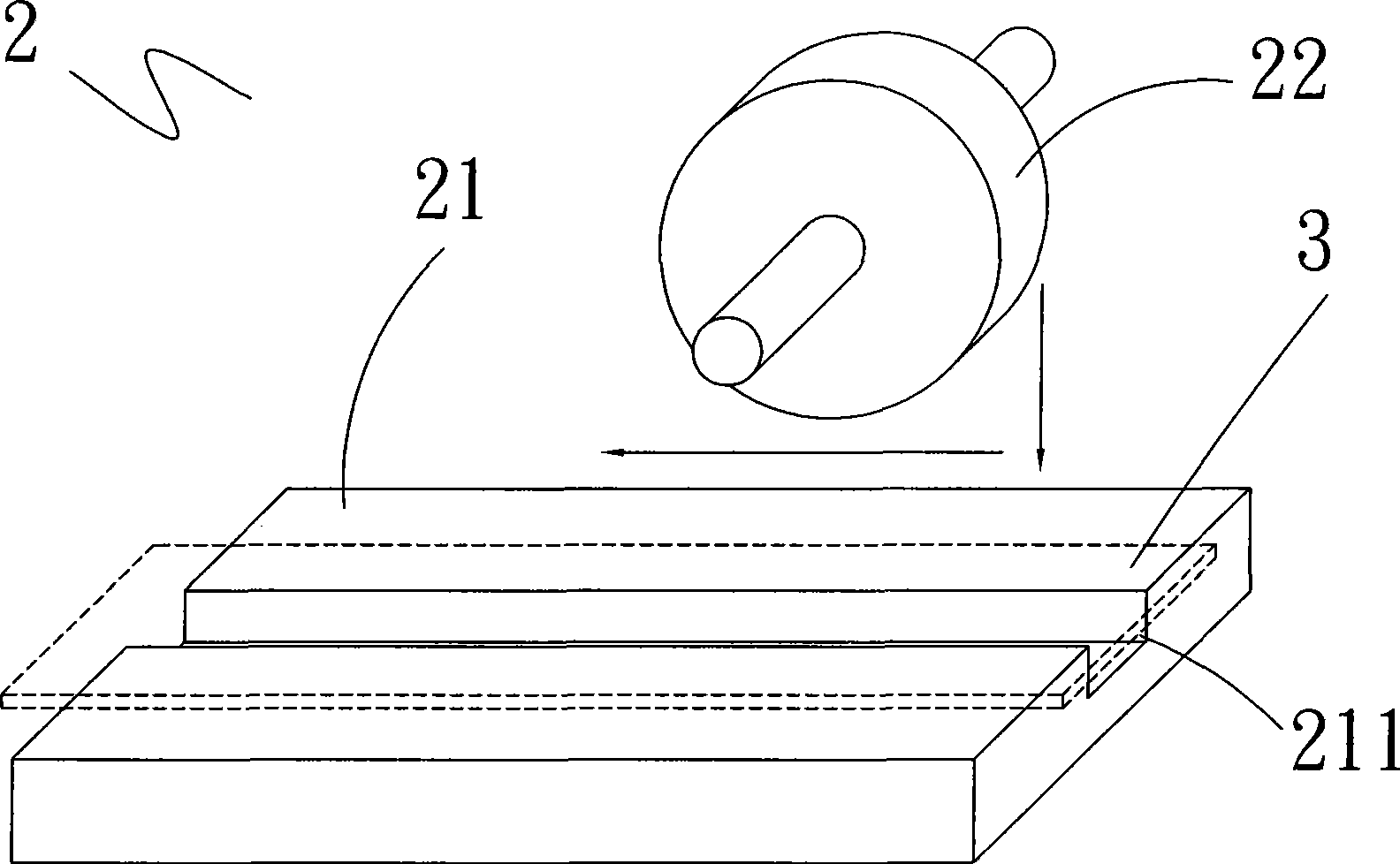

[0026] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the characteristics and functions of the preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings, so as to facilitate a complete understanding.

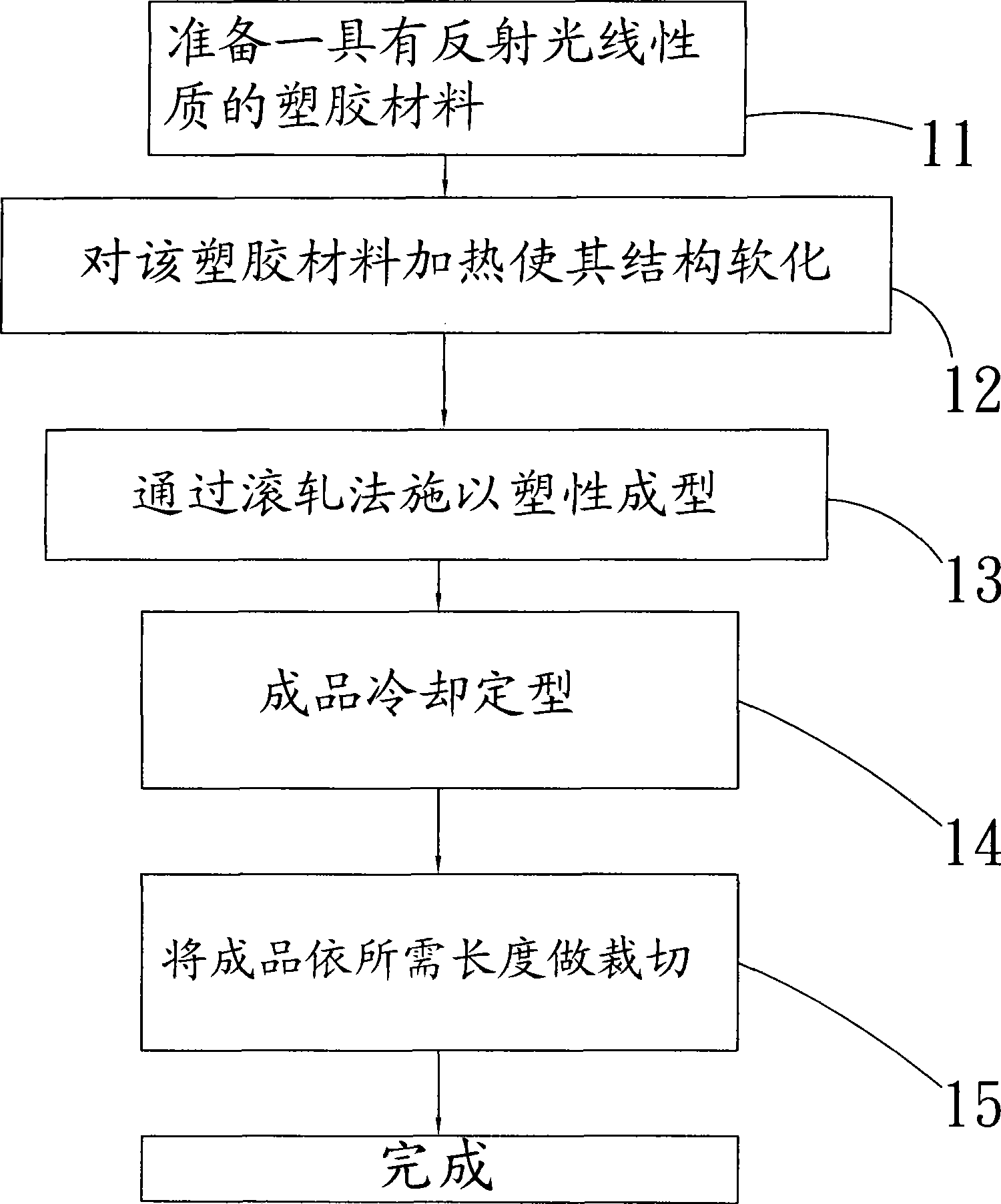

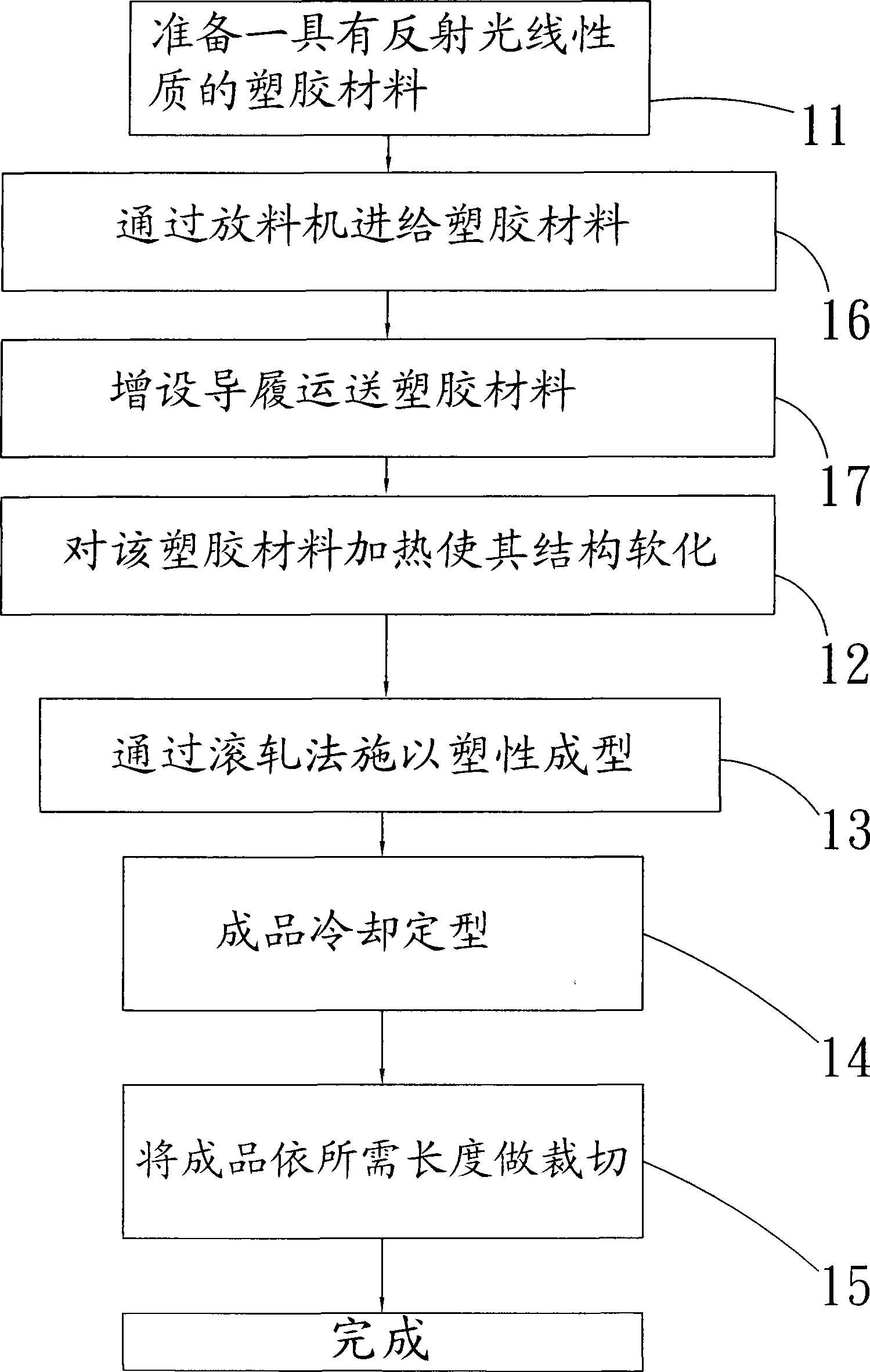

[0027] see figure 1 , which is a manufacturing flow chart of a preferred embodiment of the present invention, as shown in the figure, the manufacturing procedure of the reflector lampshade of the present invention is a method comprising the following steps:

[0028] Step 1: preparing a plastic material 11 with the property of reflecting light;

[0029] It is to prepare a plastic material with the property of reflecting light, which is a polymer material and has a good reflection effect on light;

[0030] Step 2: heating the plastic material to soften its structure by 12;

[0031] The plastic material is softened by heating to force t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com