Manufacturing method of solar battery module and solar battery module

A technology for solar cells and solar cells, applied in electrical components, chemical instruments and methods, circuits, etc., to achieve the effects of high processing efficiency, low fragmentation rate, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

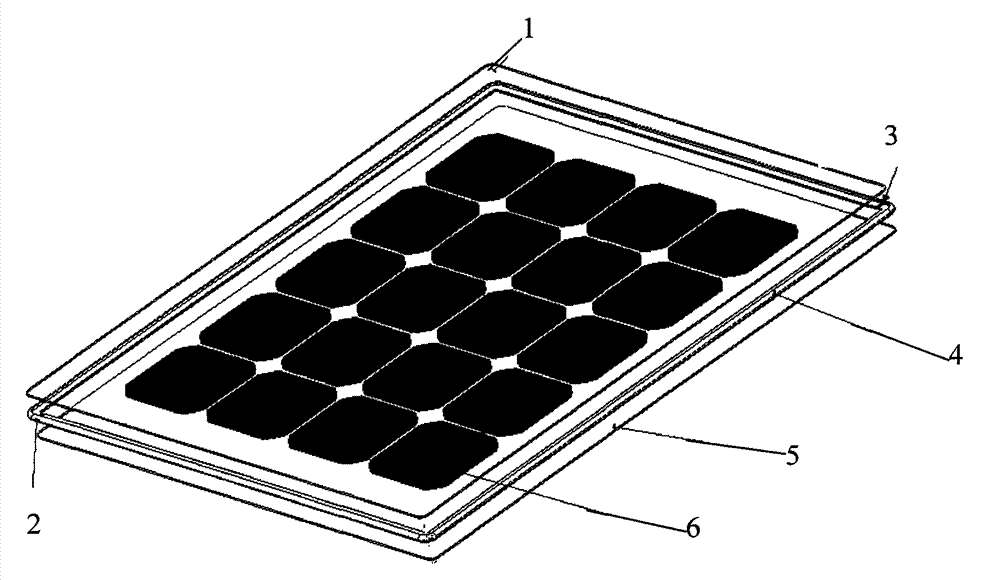

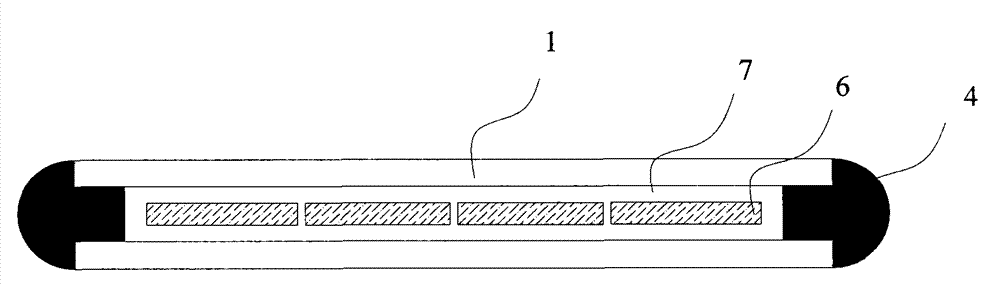

[0053] Such as figure 2 , 3 As shown, the solar cell assembly produced in this embodiment is a planar solar cell assembly.

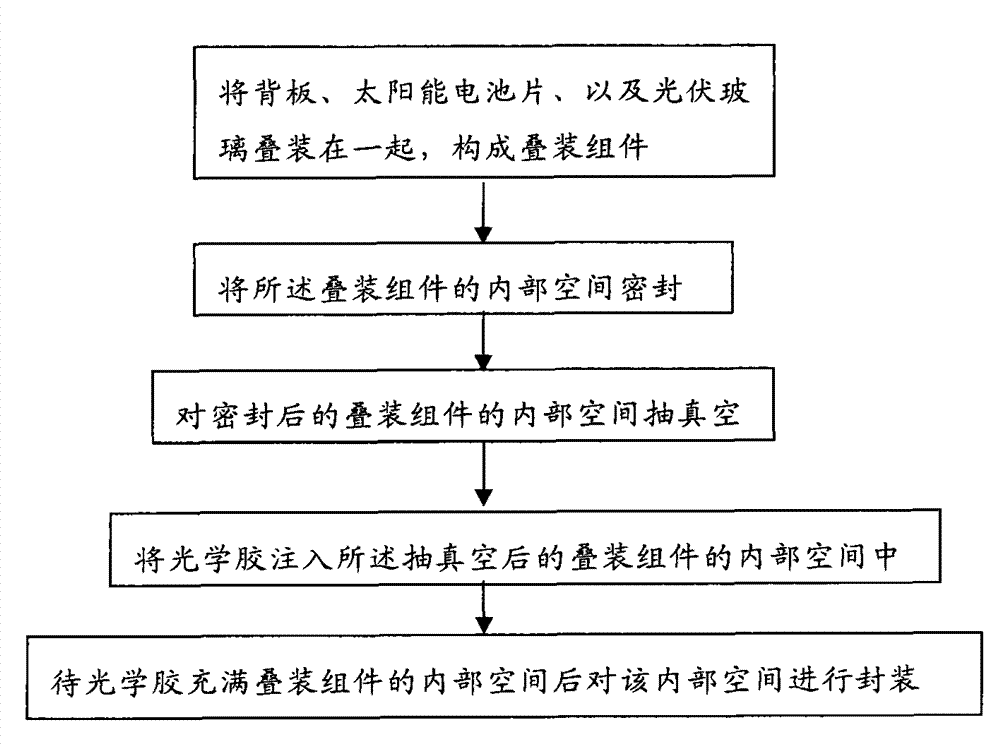

[0054] Such as figure 1 As shown, the specific steps of the manufacturing method of the planar solar cell module are as follows:

[0055] 1) After the photovoltaic glass 1 is cleaned, the back plate 5, a plurality of solar cells 6 connected in series, and the photovoltaic glass 1 are stacked to assemble a stacked assembly, wherein the solar cells 6 are in the Between the back plate 5 and the photovoltaic glass 1 in the stacked assembly, that is, in the internal space of the stacked assembly;

[0056] 2) A sealing strip 4 is provided at the edge of the internal space of the stacked assembly to seal the internal space, and a glue inlet 2 and a glue outlet 3 are provided on the sealing strip 4;

[0057] 3) Connect the glue outlet 3 to an external vacuum pump, seal the glue inlet 2 with a rubber clip, and turn on the vacuum pump connected to the glue o...

Embodiment 2

[0068] Such as Figure 4 , 5 As shown, the solar cell assembly produced in this embodiment is a curved solar cell assembly.

[0069] The difference between the manufacturing method of the solar cell module in this embodiment and the manufacturing method in Embodiment 1 is: in step 2), after sealing the inner space of the stacked module with the sealing tape 4, and then sealing the The two ends of the above-mentioned stacked assembly are respectively fixed on the slots 8 of the manufacturing tool, and then the soft film 9 is installed on the back plate 5 . The soft film 9 forms a sealed space in the curved solar cell assembly, and can adapt to the shape of the curved surface assembly, allowing optical glue to be injected to form the curved surface solar assembly.

[0070] Since the shape of the solar cell module in this embodiment is a curved surface, it cannot be directly placed on a horizontal surface for processing, so it is placed on the tooling slot 8 to facilitate subse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com