A kind of regeneration method of the catalyst that prepares propylene oxide by propylene epoxidation

A catalyst and epoxidation technology, applied in catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as difference in catalytic performance and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

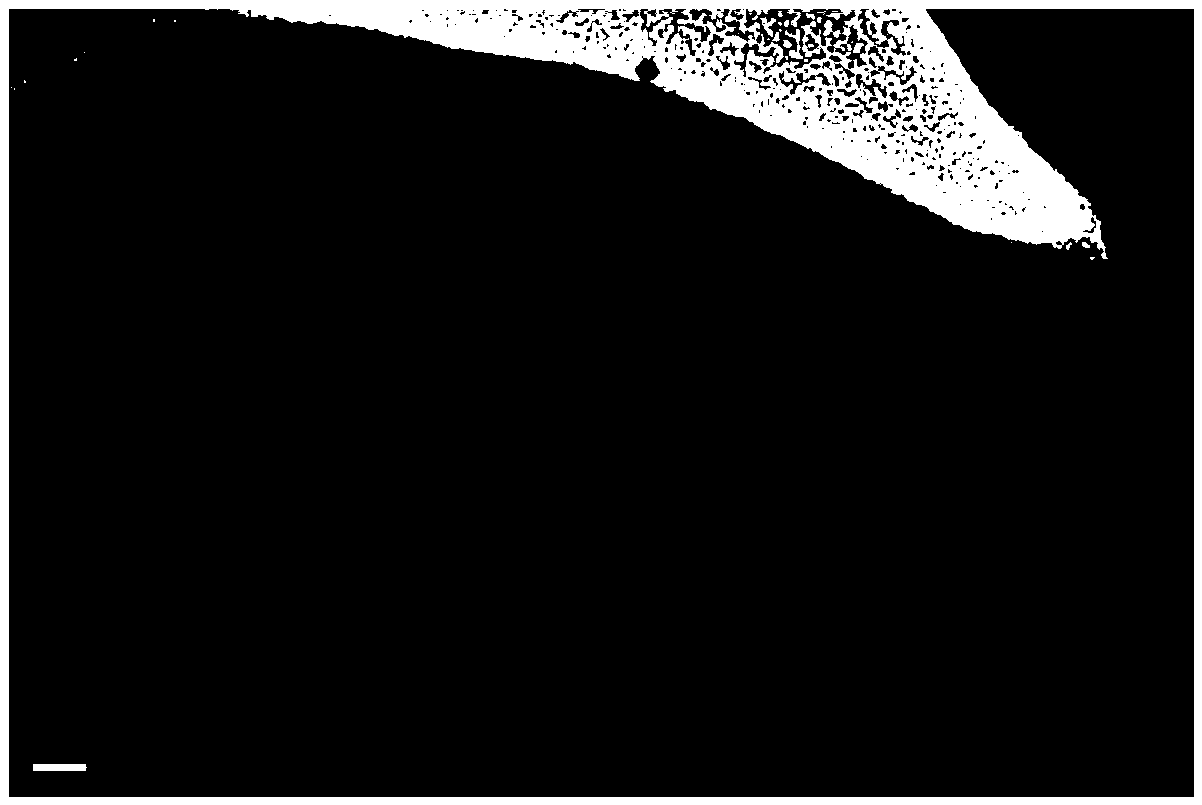

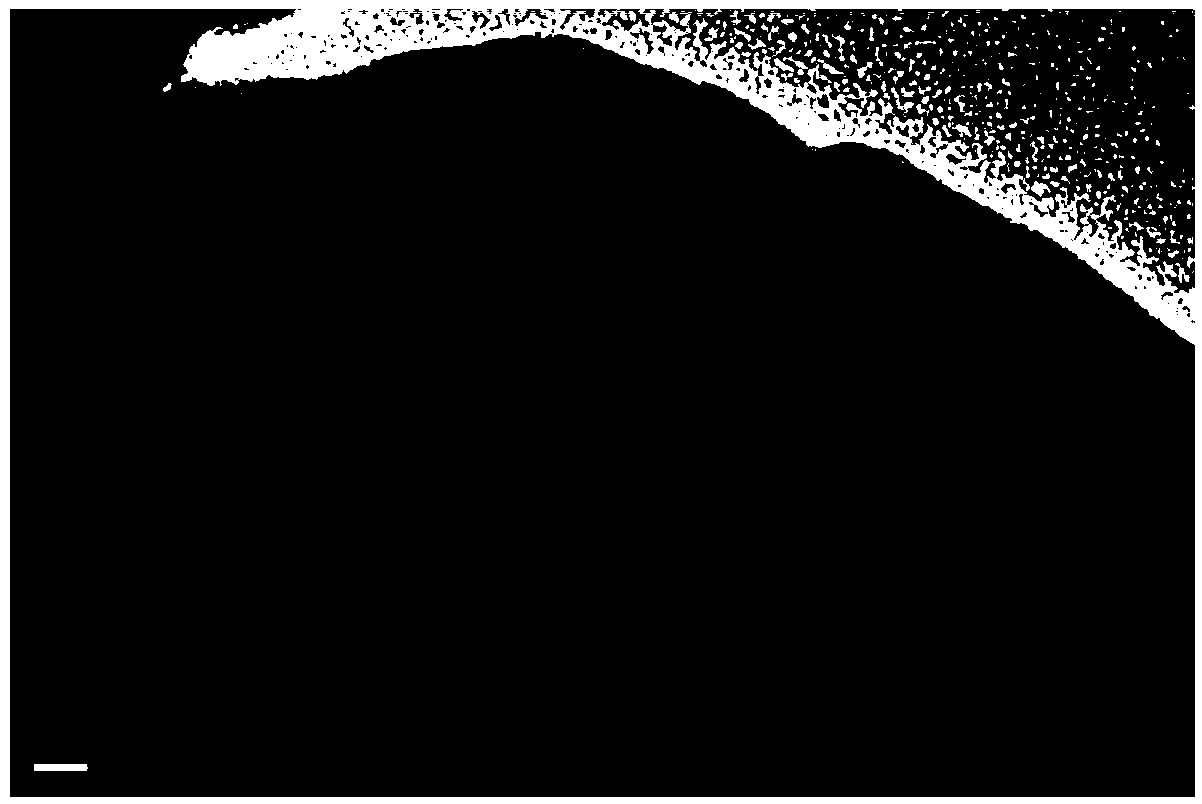

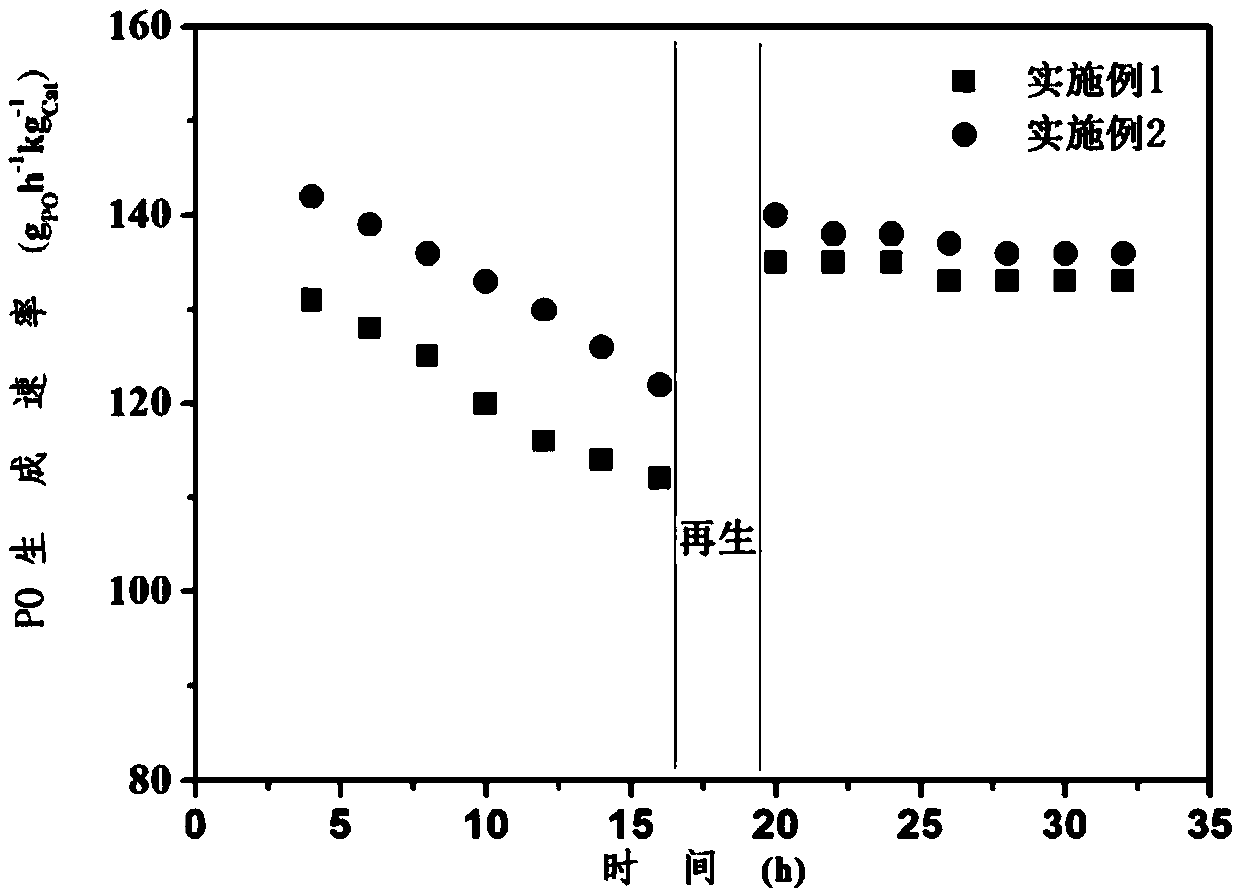

[0061] The fresh 0.1%Au / TS-1 catalyst was loaded in the fixed bed reactor, the catalyst loading was 0.15g, and the evaluation was carried out according to the conventional conditions. The regeneration experiment was carried out on the deactivated catalyst after a period of time: the reaction gas was switched to air, the temperature was raised to 300 degrees at a rate of 5 degrees per minute, and the catalyst was regenerated for 3 hours. See attached for regeneration results Figure 1-3 .

[0062] The results show that the regeneration method proposed by the invention can effectively recover the catalytic performance of the catalyst.

Embodiment 2

[0064] The fresh 0.15% Au / TS-1 catalyst was loaded in the fixed bed reactor, the catalyst loading was 0.15g, and the evaluation was carried out according to the conventional conditions. After a period of time, the deactivated catalyst was regenerated: switch the reaction gas to hydrogen: oxygen: nitrogen = 0.1:1.9:8, raise the temperature to 300 degrees at a rate of 10 degrees per minute, and regenerate the catalyst for 2 hours. See attached for regeneration results image 3 .

[0065] The results show that the regeneration method proposed by the invention can effectively recover the catalytic performance of the catalyst.

Embodiment 3

[0067] The fresh 0.10% Au / TS-1-1-butyl-3-methylimidazolium tetrafluoroborate catalyst was loaded in the fixed-bed reactor, and the catalyst loading was 0.15g, and the evaluation was carried out according to the conventional conditions. The deactivated catalyst was regenerated after a period of time: switch the reaction gas to oxygen: argon = 2:8, raise the temperature to 280 degrees at a rate of 5 degrees per minute, and regenerate the catalyst for 2.5 hours. See attached for regeneration results Figure 10 .

[0068] The results show that regenerating the catalyst containing promoters by the method proposed by the invention can also effectively recover the catalytic performance of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com