Rapid solidification metal strip production device and method thereof

A production device and rapid technology, applied in the field of metal rapid solidification, can solve the problem of inability to form large-scale production, and achieve the effect of high output and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

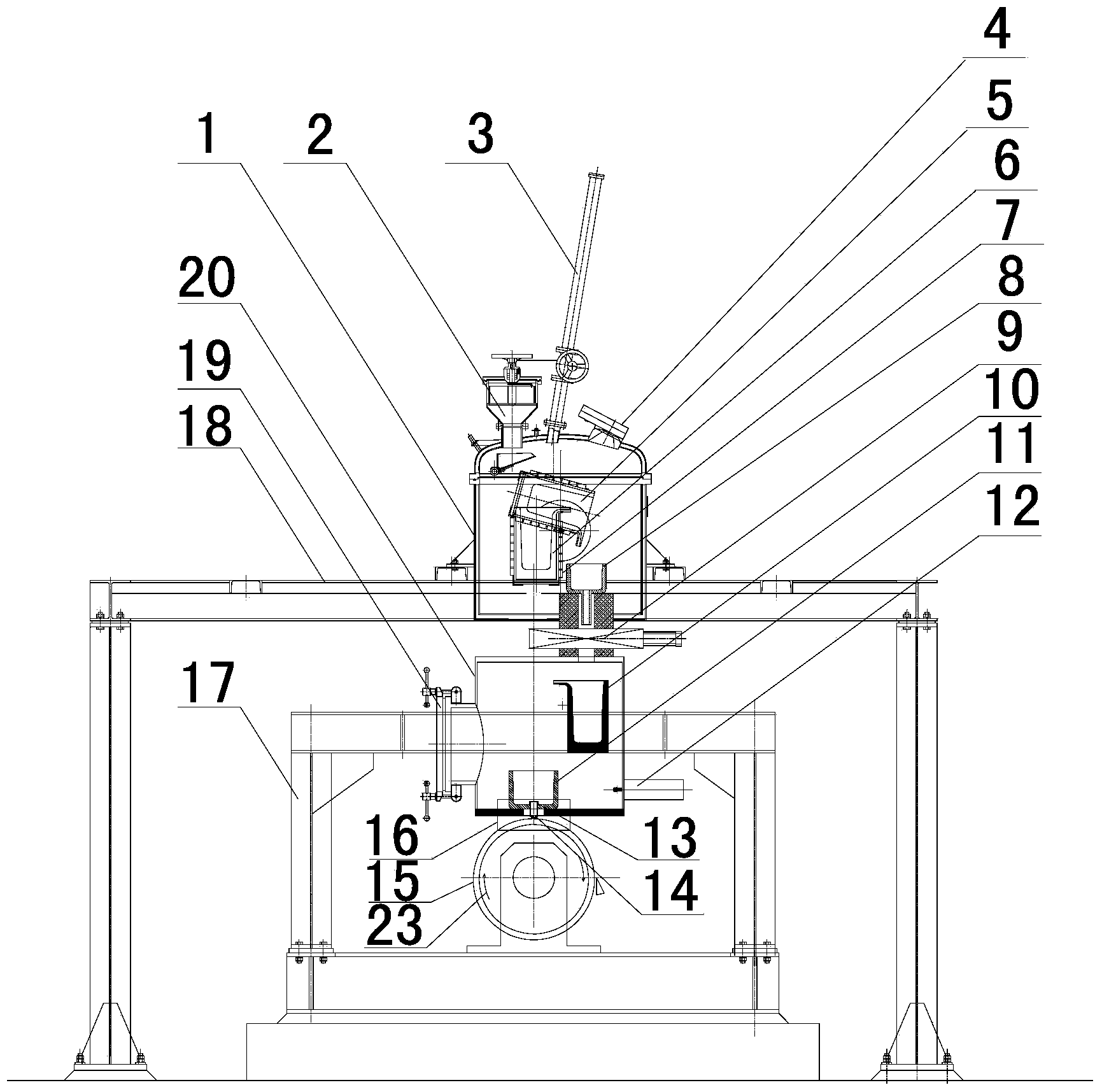

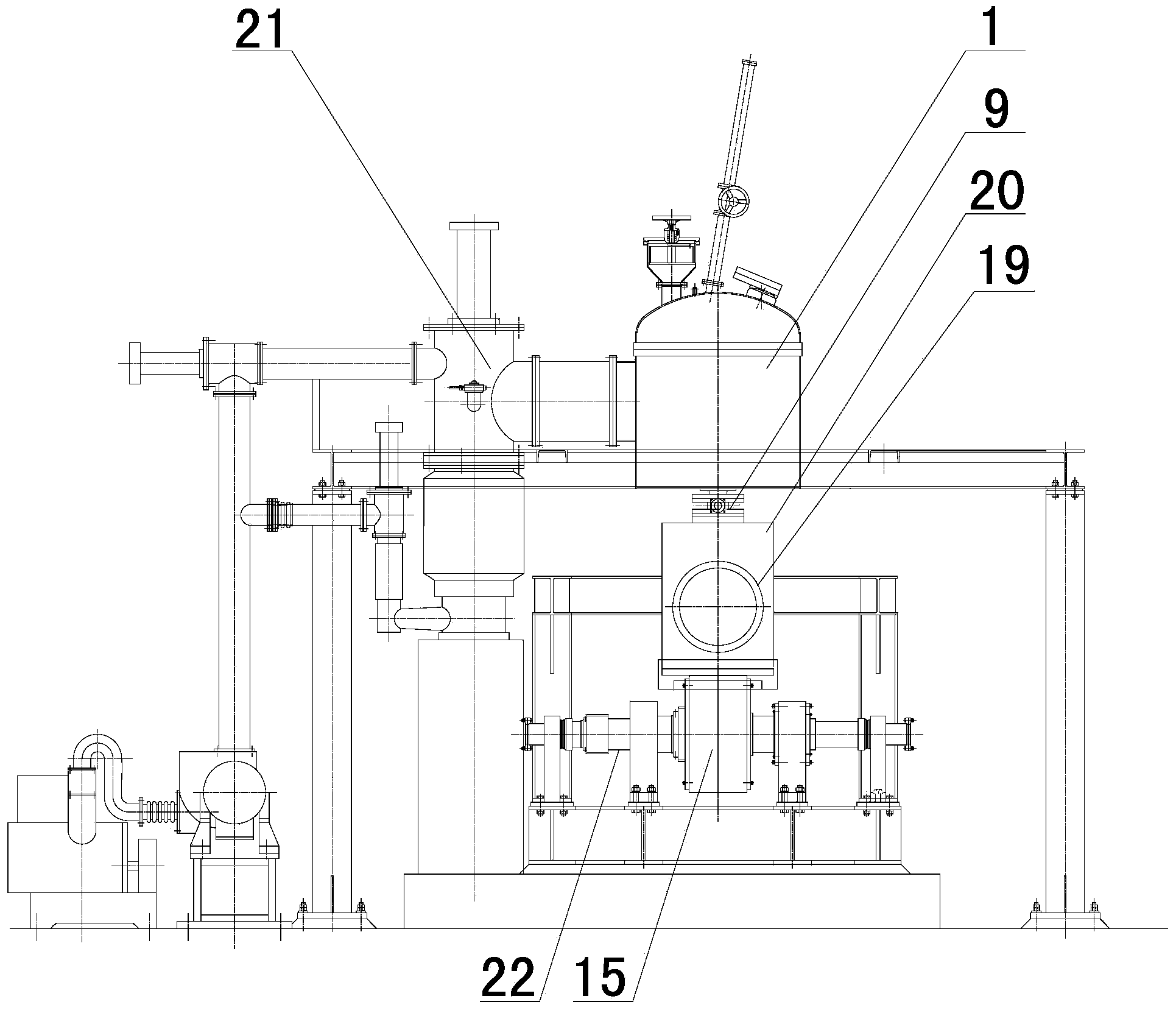

[0028] see figure 1 , figure 2 Shown: a metal rapid solidification strip production device, it includes a vacuum smelting furnace 1, a vacuum system 22, a nozzle 14, a water-cooled copper roll 15, and it also includes a nozzle package 20, which is connected to the nozzle package at the lower end of the vacuum smelting furnace Between the upper ends of 20, there is a flapper valve 9 communicating up and down, and an intermediate liquid-holding crucible 10 and a nozzle-package crucible 11 are arranged in the nozzle package 20. The cladding crucible 11 is arranged at the lower part of the middle liquid-containing crucible 10, and a nozzle 14 is connected to the lower end of the nozzle cladding crucible 11, and a nozzle cover 13 is placed on the nozzle 14, and a water-cooled copper roller 15 is arranged at the bottom of the nozzle 14.

[0029] On the vacuum melting furnace 1, an alloy feeding device 2, a temperature measuring device 3, and an observation window 4 are also arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com