Automatic sealing ring assembling equipment

A technology of automatic loading and sealing ring, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of small use range and low assembly efficiency, and achieve the effect of improving assembly efficiency and simplifying manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

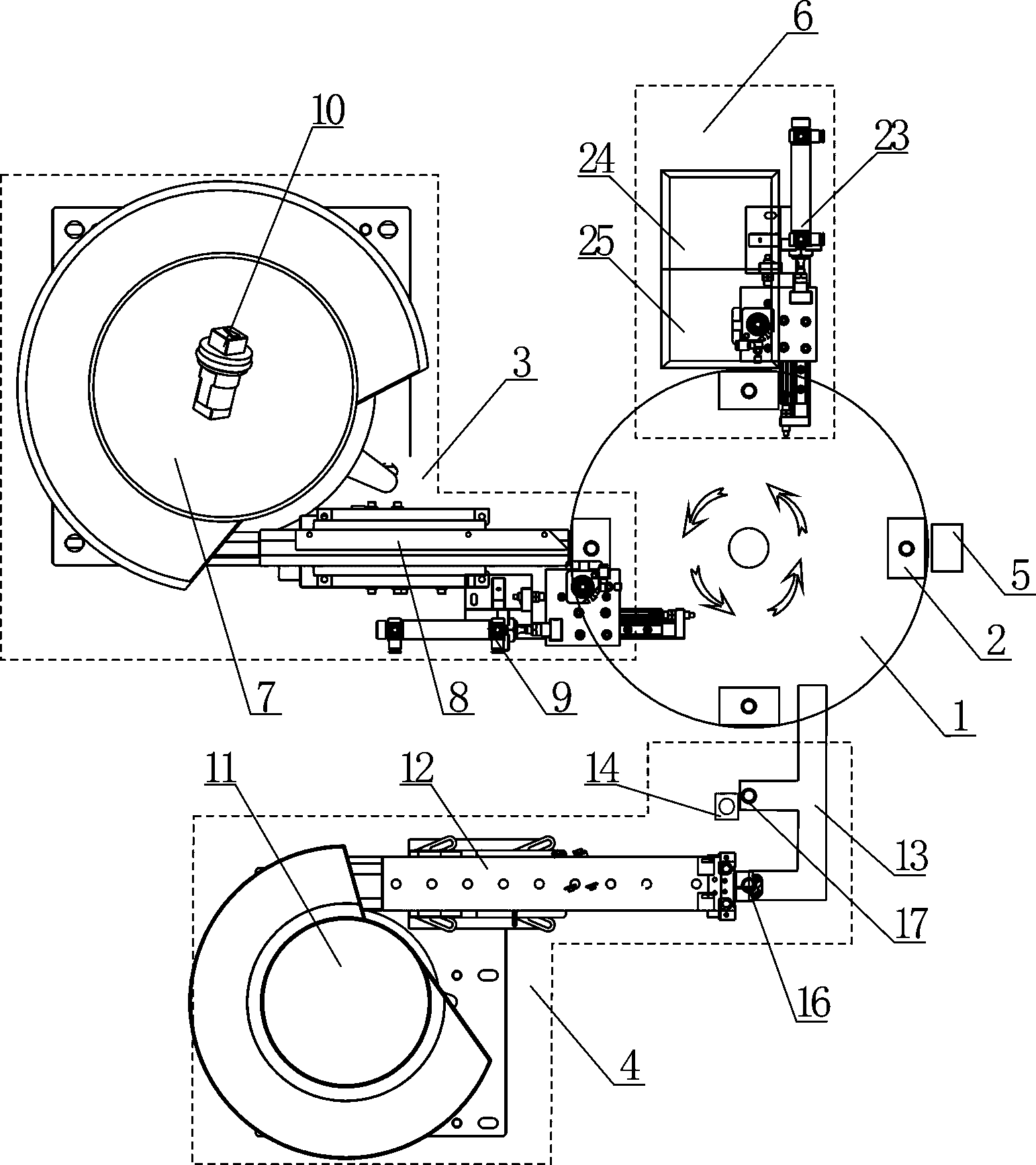

[0017] Such as figure 1 As shown, the sealing ring is automatically loaded into the equipment, including a four-station intermittent turntable 1, and four jigs 2 are evenly distributed on the four-station intermittent turntable 1 along its periphery, surrounding the four-station intermittent turntable 1. According to the successive procedures, there are metal cylindrical parts feeding device 3, sealing ring feeding and loading device 4, sealing ring in-position detection device 5 and assembly part taking out device 6.

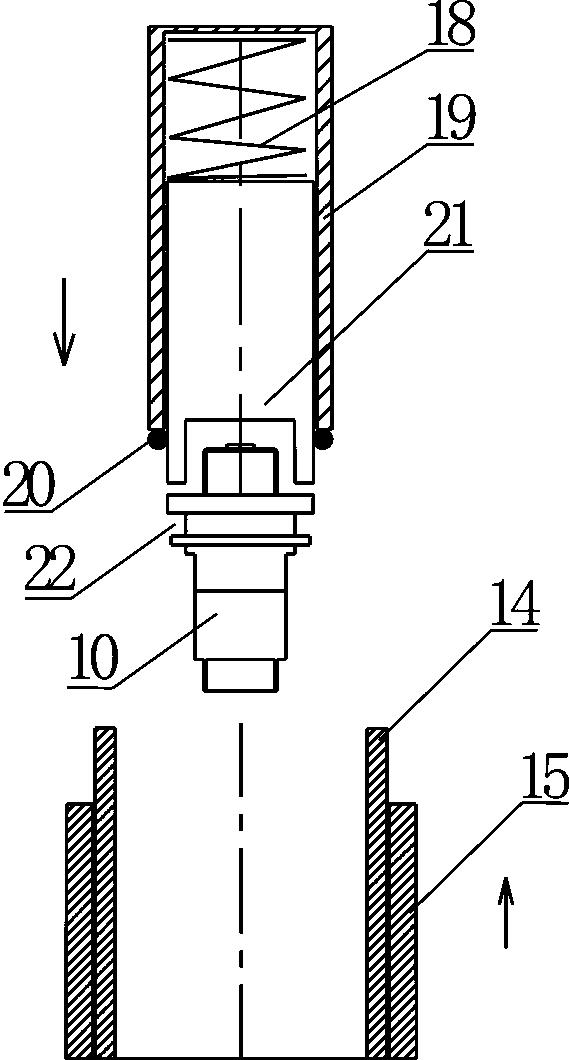

[0018] The metal cylindrical piece feeding device 3 is mainly composed of a vibrating plate 7, a linear feeder 8, an optical fiber sensor, and a manipulator 9. The vibrating plate 7 sends the metal cylindrical piece 10 into the linear feeder 8, and the linear feeder 8. Transfer the metal cylinder to the designated position. When the optical fiber sensor senses the metal cylinder 10, start the manipulator 9. The manipulator 9 grabs and inserts the metal cylinder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap