Automatic Self-Centering Fixtures

A self-centering fixture and automatic technology, applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of clamping force, processing deformation, etc., and achieve the effects of small processing deformation, high positioning accuracy, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

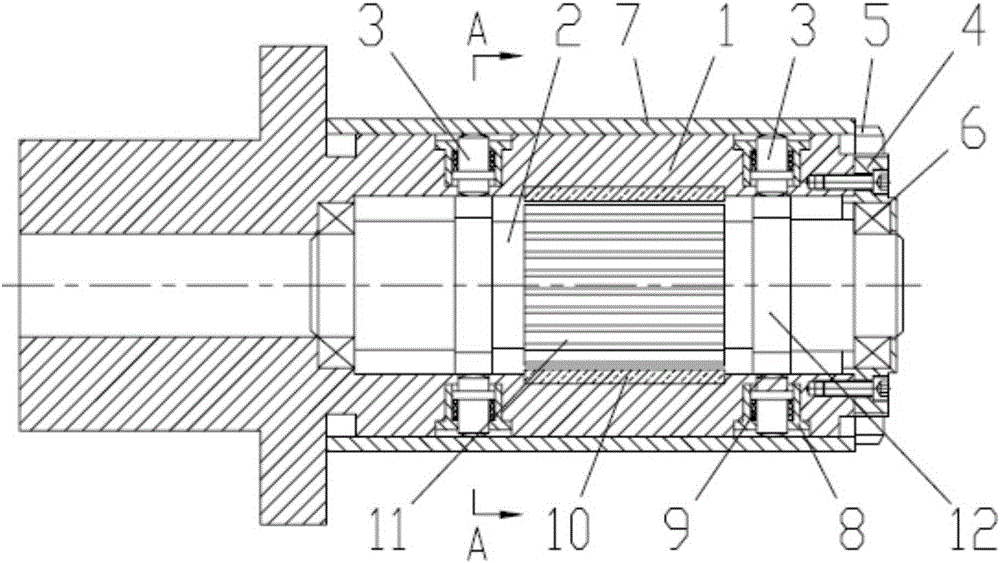

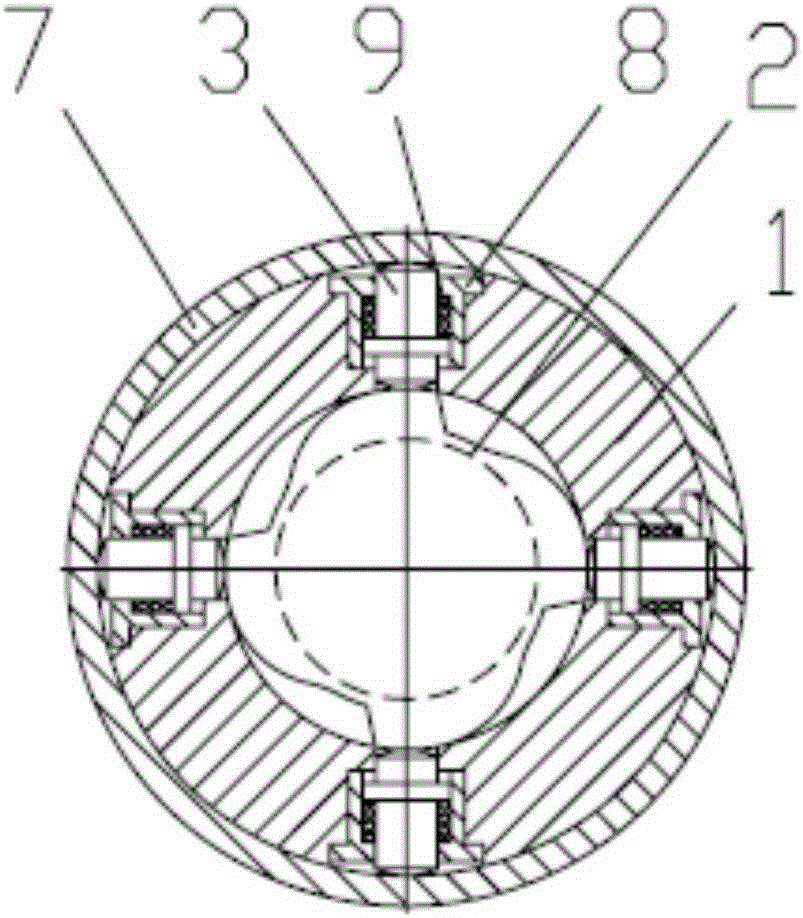

[0010] Such as figure 1 , as shown in 2, an automatic self-centering fixture, including mandrel 1, rotor shaft 2, positioning clamping column 3, end cover 4, end face compression nut 5, bearing 6, guide sleeve 8, return spring 9, motor Stator 10, motor rotor 11, outer cam column 12.

[0011] One end of the positioning column of the mandrel 1 is provided with a positioning step, the outer circle of the mandrel 1 is a positioning cylinder, a stepped inner hole is arranged in the positioning cylinder of the mandrel 1, and at least two A group of radial through holes, each group of radial through holes is evenly distributed with three or four radial through holes on the same cross section of the positioning column, the radial through holes are fixedly connected with a guide sleeve 8, and the guide sleeve 8 is movable Cooperate with the positioning clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com