Pipe withdrawing tongs

A pipe retracting wrench and pipe technology, applied in the field of machinery, can solve problems such as infrequent disassembly, impact on life, and difficulties, and achieve the effects of labor-saving operation, prolonging service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below, and the following embodiments are based on the technical solutions of the present invention, and provide detailed implementation methods and specific operation processes. It should be noted that any modification, equivalent replacement, variation and improvement made by those skilled in the art without departing from the concept of the present invention shall fall within the protection scope of the present invention.

[0019] The invention provides a pipe withdrawing wrench, which is used for withdrawing a small-diameter pipe nested in a large-diameter pipe, such as a rubber pipe of a gas pipe and other similar pipes installed through nesting.

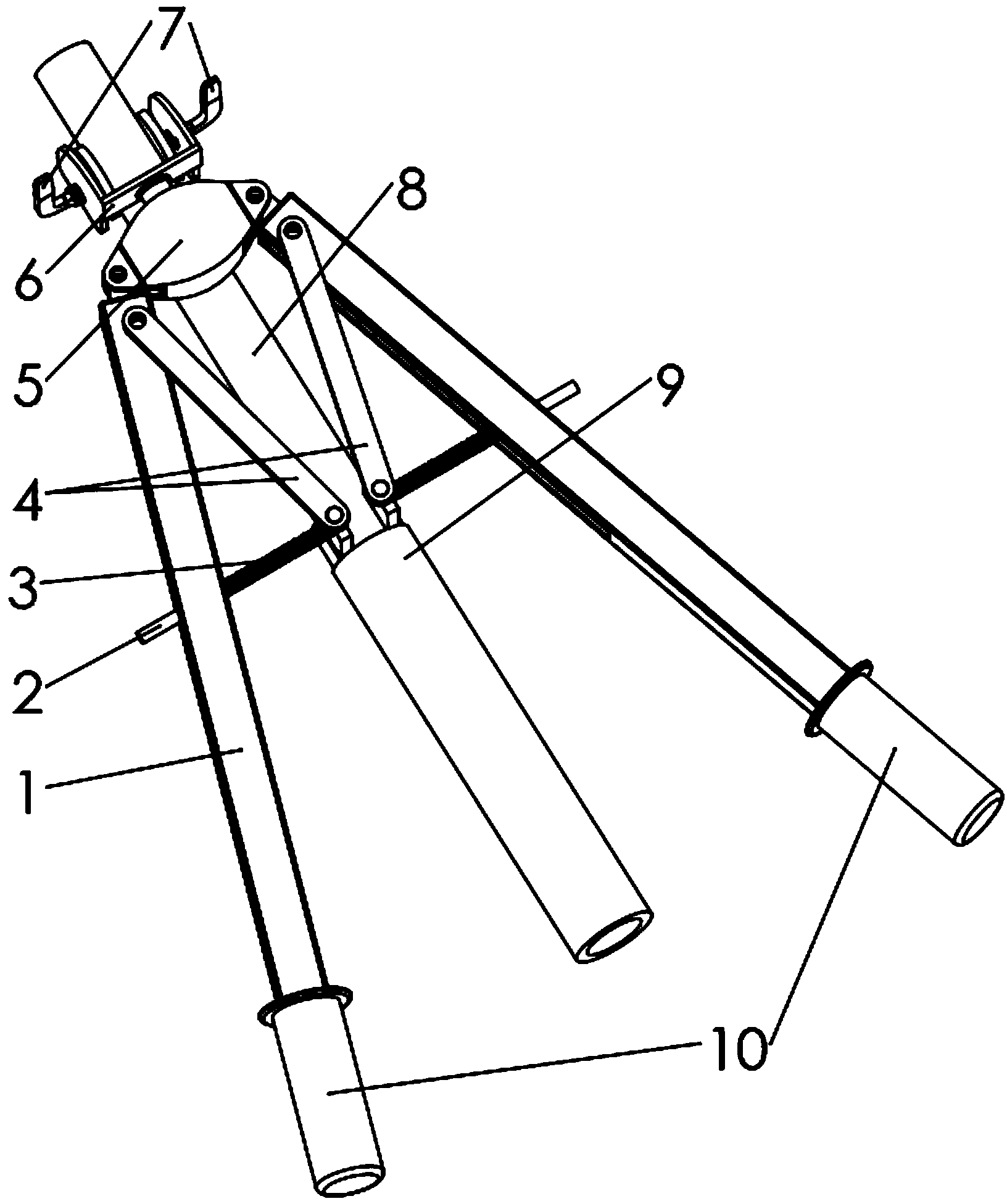

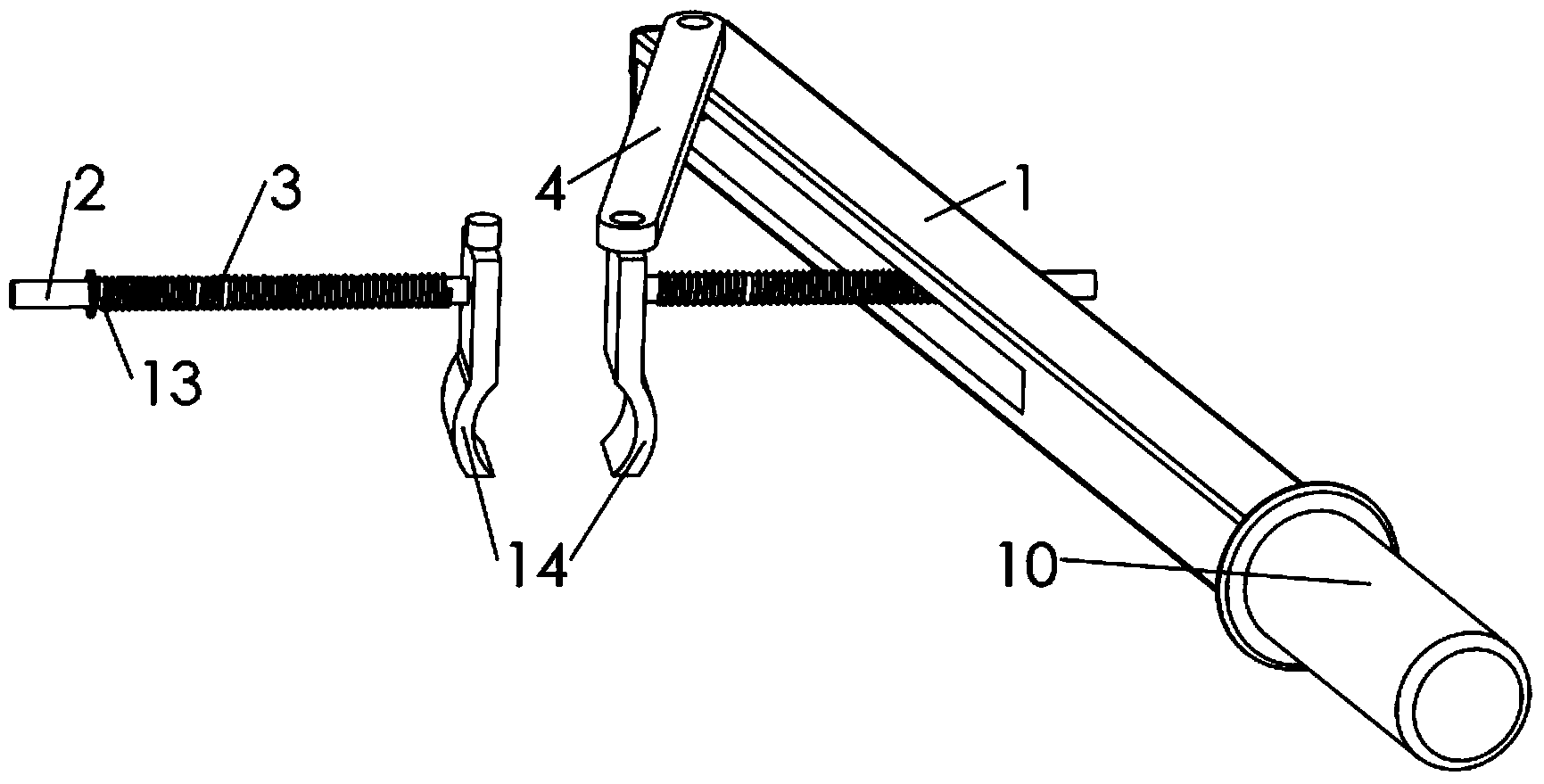

[0020] see figure 1 , This embodiment includes a collet, a shuttle-shaped connecting block 5, two operating rods 1, two poles 4, two ferrules 14, two thimbles 2 and two springs 3.

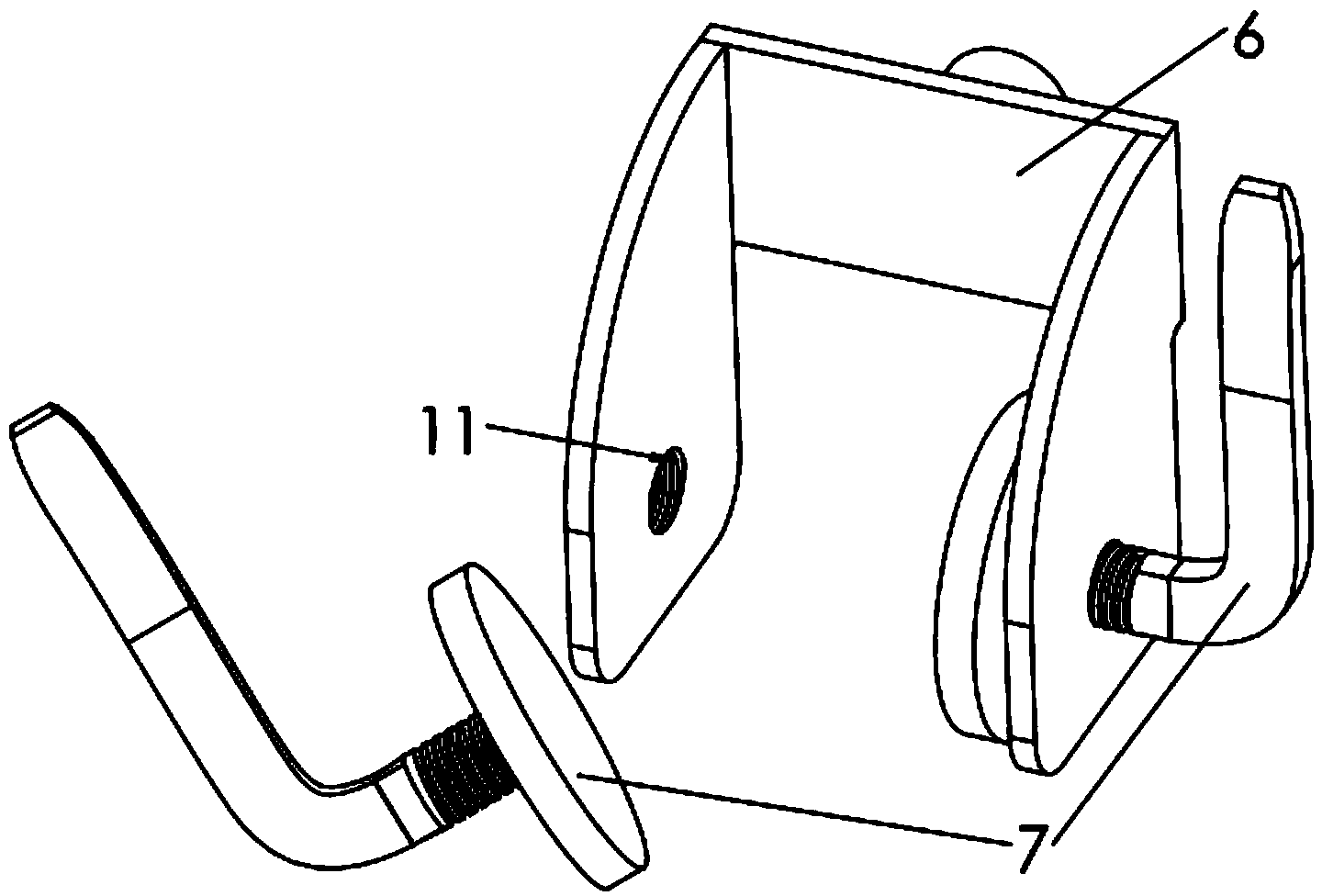

[0021] see figure 2 , the chuck is fixedly connected to the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com