Shaver, shaver foil and manufacturing process of shaver foil

一种制造工艺、剃须刀的技术,应用在金属加工等方向,能够解决制造成本高、不利产业发展、效果不理想等问题,达到提高舒适度和干净度、均匀度好、保证强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

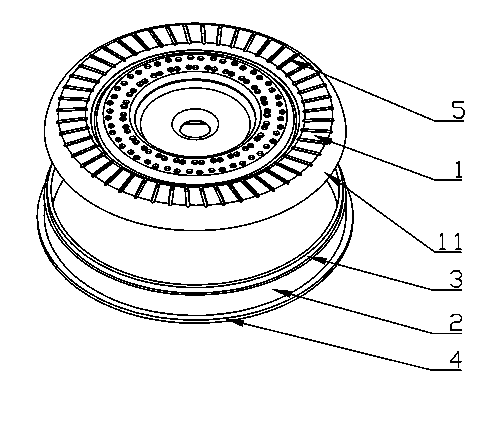

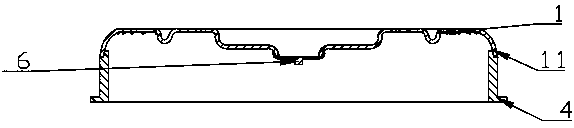

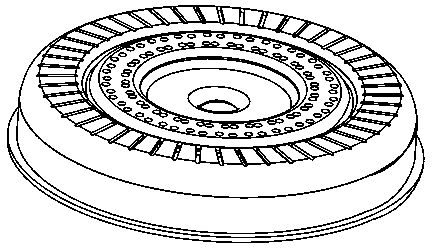

[0031] Such as figure 1 combine Figures 2 to 4 As shown, a razor blade net includes a knife net surface 1 and a knife net housing 2. The knife net surface 1 is provided with several mesh slits 5, and the lower part of the knife net surface 1 extends with Welding part 11, the knife screen housing 2 is in the shape of a ring, the lower edge of the knife screen housing 2 is integrally formed with a snap ring 4, and the knife screen mesh surface 1 is sleeved on the knife screen housing 2 The upper part is welded with the knife screen housing 2 through the welding part 11.

[0032] A blade positioning platform 6 is welded at the center of the knife screen surface 1 , and the blade positioning platform 6 is located on the inner surface of the knife screen surface 1 . For mounting rotary blades.

[0033] The said knife net housing 2 is provided with an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com