Vertical type injection molding machine with guide structure

An injection molding machine, vertical technology, applied in the field of vertical injection molding machines, can solve the problems of slow moving speed, easy shaking damage, poor guide position of the movable plate, etc., to achieve the effect of fast and accurate guide position and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

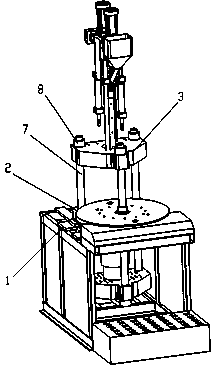

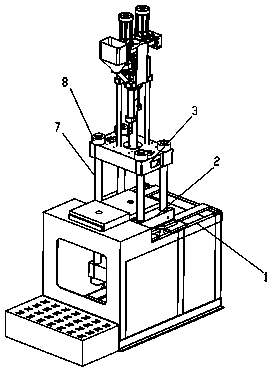

[0017] Existing vertical injection molding machines such as figure 1 and figure 2 Shown, comprise platform 1, fixed plate 2 and movable plate 3, fixed plate 2 is fixed on the platform 1, and fixed plate 2 is provided with several guide pillars 7, and fixed nut 8 is equipped with on the upper end of guide column 7, movable plate 3 is installed on the guide post 7, and can slide between the fixed plate 2 and the fixed nut 8. Its guide post is three to form a triangle (such as figure 1 shown) or four quadrilaterals (such as figure 2 shown).

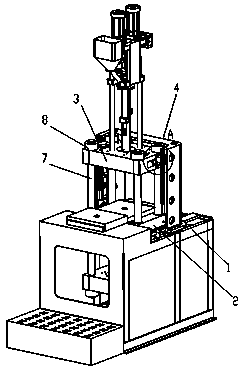

[0018] The guiding structure that the present invention increases is as image 3 and Figure 5 As shown, by installing a C-shaped guide frame 4 on the side of the guide post 7, the guide frame 4 half surrounds the guide post 7 to stabilize the movable plate 3. The connection of movable plate 3 and 4 guide frame 4 is as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com