Manufacturing method of inductor

A manufacturing method and inductor technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve problems affecting the quality of finished inductors, inaccurate installation, etc., to facilitate automatic assembly line production and convenient processing and production , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

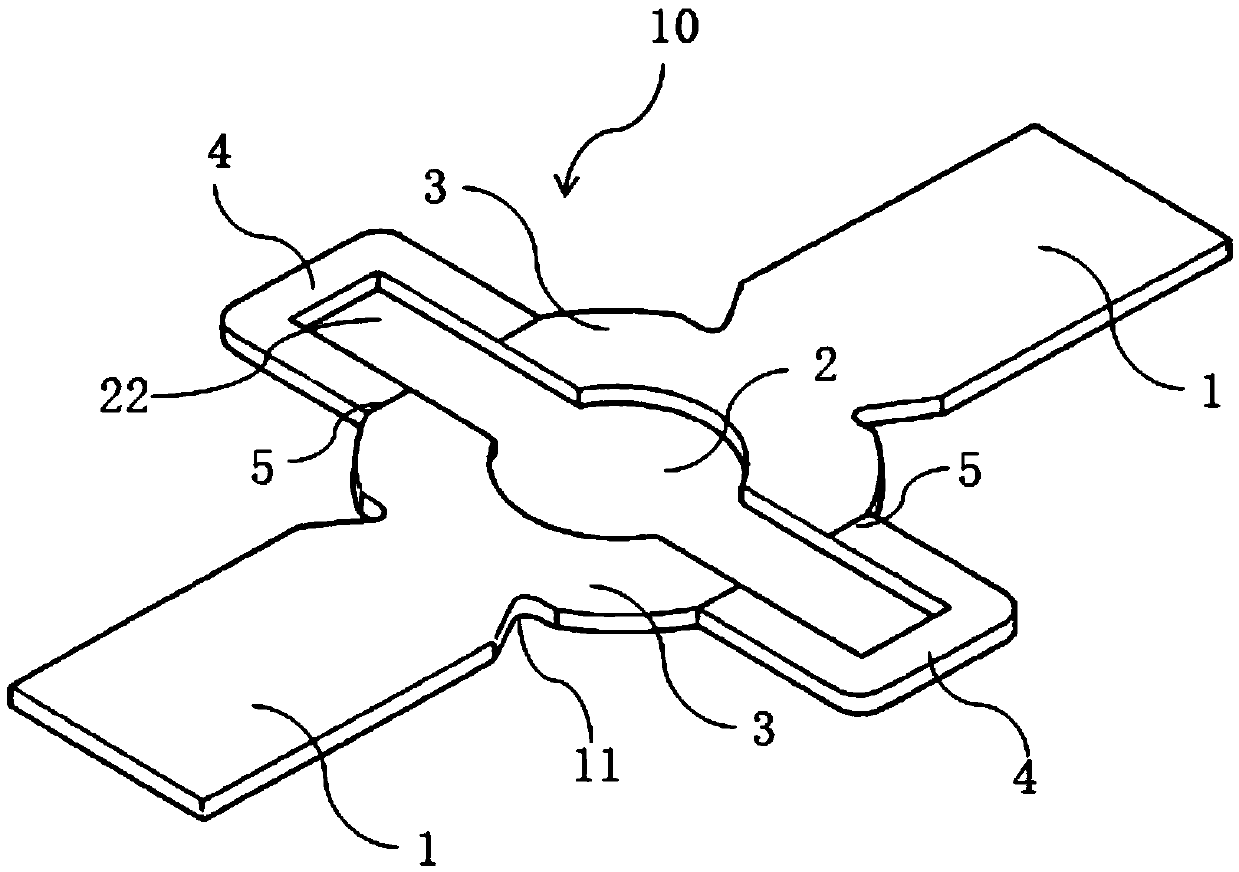

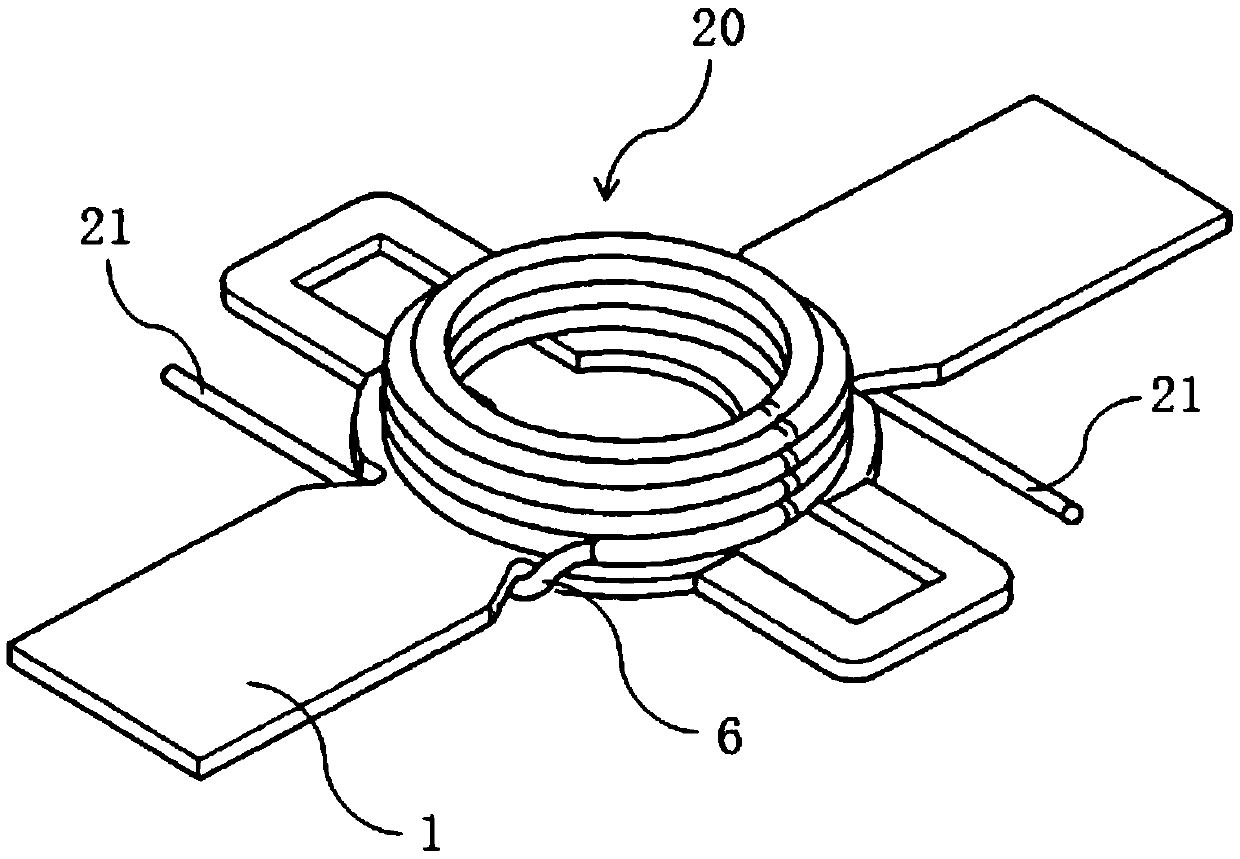

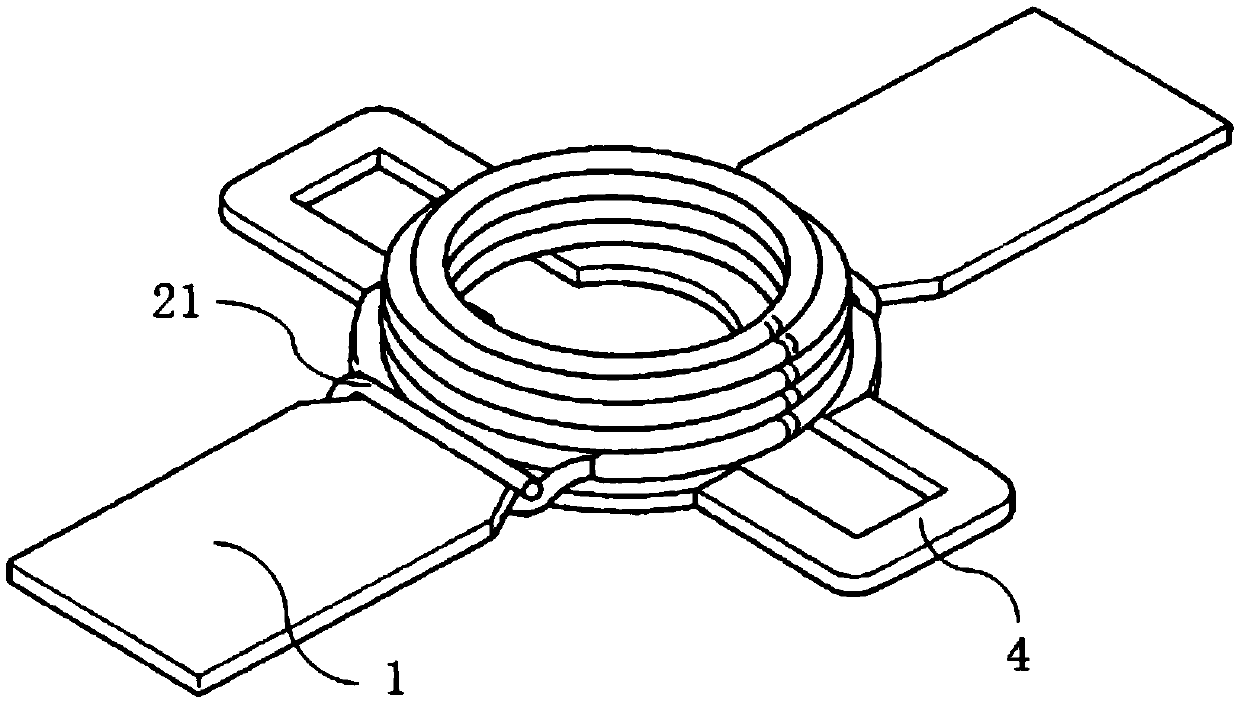

[0017] Such as Figure 1 to Figure 6 As shown, the manufacturing method of the inductor of the present embodiment includes the following steps: S1) integrally stamping a metal sheet to form a sheet-shaped body 10, the sheet-shaped body 10 includes two relatively protruding pins 1, and the two pins 1. Supporting parts 3 separated by holes 2 in the middle are respectively provided on the opposite inner sides. The two supporting parts 3 form a tray. Connecting parts 4 are provided between the supporting parts 3. Each of the two connecting parts 4 is provided with a breakable concave tangent line 5; S2) Wind a helical coil 20 with a metal wire 6, the bottom end of the coil 20 protrudes from the extension section 21, and the coil 20 is placed on the surface of the tray, so that the two extension sections 21 extend out from the joint between the pin 1 and the support part 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com