A car independent suspension system

An independent suspension, automobile technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of large lateral occupied space, small lateral occupied space, unsatisfactory wheel camber angle change law, etc., to achieve small lateral space occupancy , excellent anti-roll performance, good application value and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

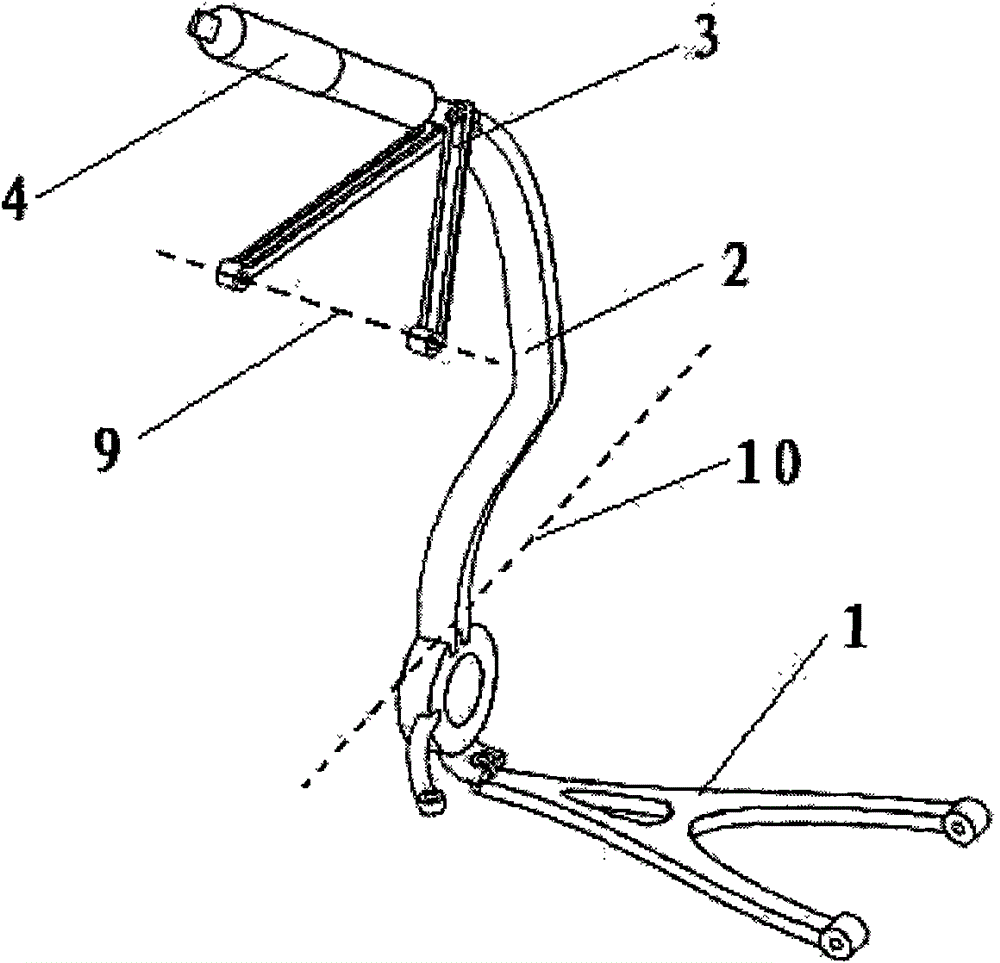

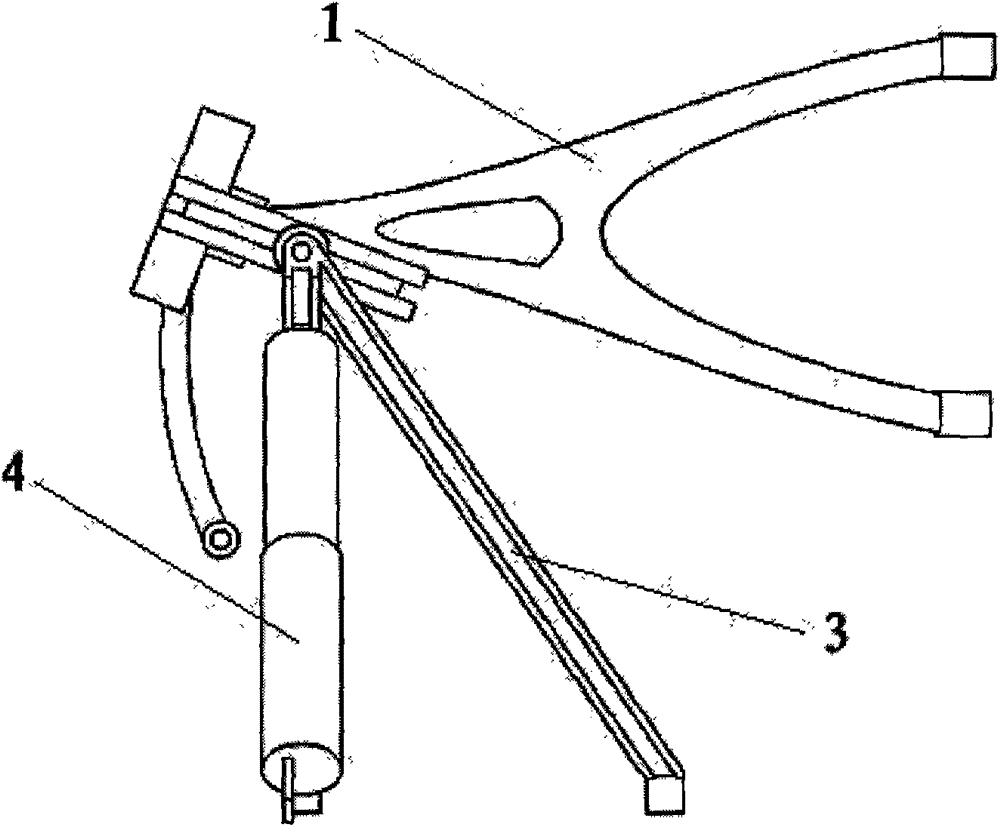

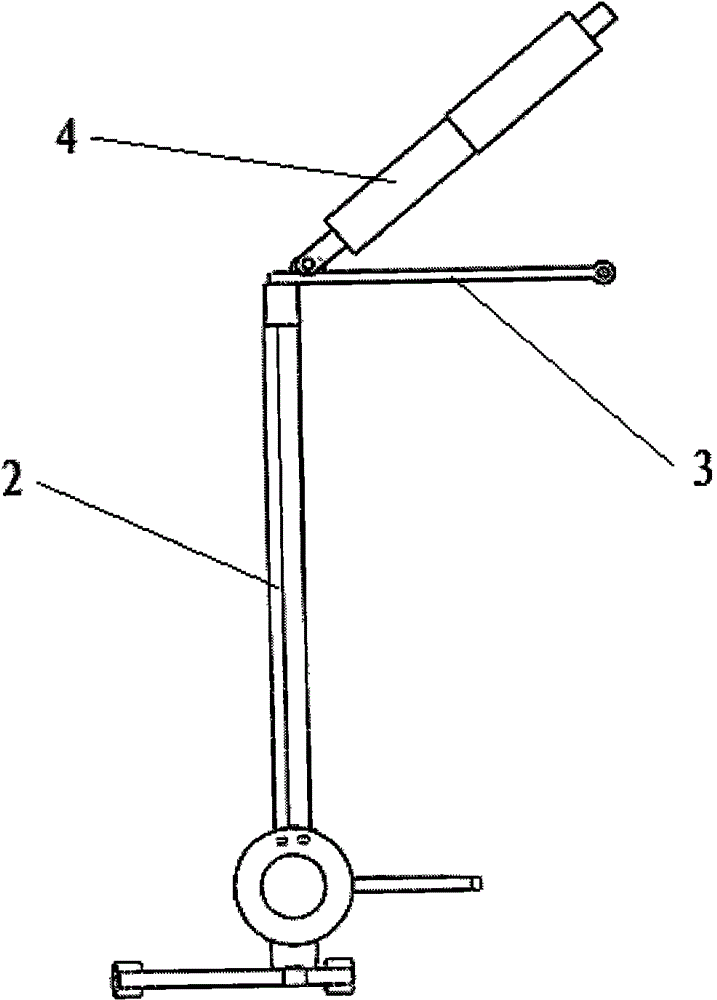

[0019] refer to Figure 1-2 , an independent suspension system for automobiles in the present invention, comprising: a shock absorbing spring 4, a steering knuckle 2, a lower wishbone 1, a connecting ball joint, and an upper wishbone 3; the upper wishbone 3 has a V-shaped structure, and the V-shaped The top of the structure is connected to one end of the steering knuckle 2 through a ball joint, and the free end of the V-shaped structure is hinged to the frame. The rotation centerline 9 of the upper wishbone 3 is parallel to the transverse axis of the vehicle and forms an angle with the longitudinal axis of the vehicle 10. , the upper wishbone 3 swings up and down in the length direction of the vehicle body around the center line of rotation; the other end of the steering knuckle 2 is connected to the lower wishbone 1 through a ball joint, and the free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com