Safe landing door for vertical hoisting device

A technology for lifting equipment and landing doors, which is applied to elevators, transportation and packaging in buildings. It can solve problems such as low efficiency, large impact loads on landings and cages, and complicated processes, and achieve convenient storage and placement. , Eliminate potential safety hazards, improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

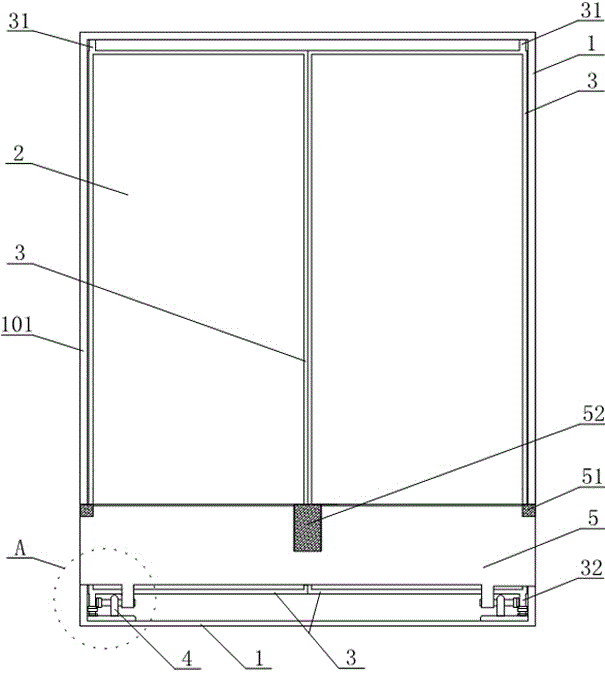

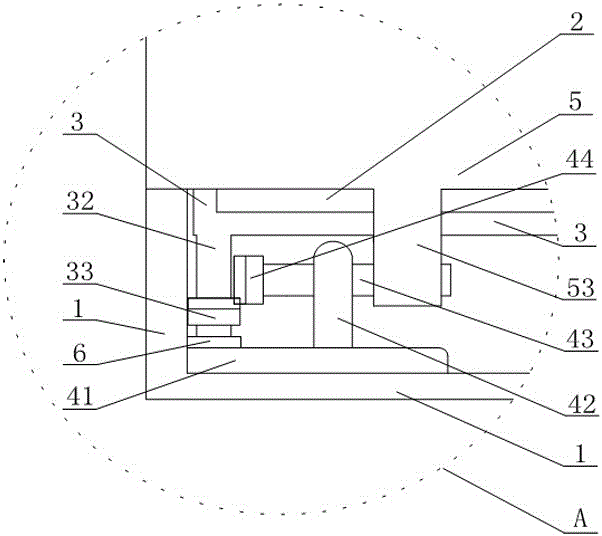

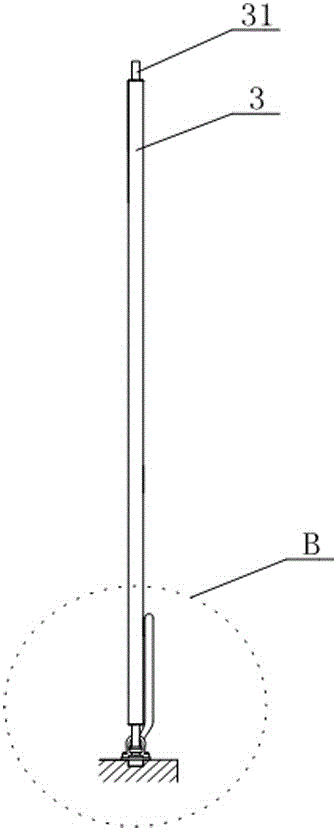

[0040] Such as Figure 1~6 As shown, a safety landing door for vertical lifting equipment includes a door frame 1 and a door leaf 2, one on the left and one on the left and right of the door leaf 2, the door leaf 2 is movably arranged on the door frame 1, and an expansion board is connected to the bottom of the door frame 1 through a movable connection device 4 5. The expansion board 5 can cover the gap between the vertical lifting equipment and the landing door after being flipped down. The movable connection device 4 includes a base plate 41, a bearing seat 42 and a rotating shaft 43. The base plate 41 is two pieces. They are respectively fixed on the left and right sides of the bottom of the door frame 1, a bearing seat 42 is fixed on each base plate 41, and a rotating shaft 43 horizontally penetrating through the bearing seat 42 is respectively fixed on the left and right two bearing seats 42, and the expansion board 5 is Rectangular, its lower end is provided with left an...

Embodiment 2

[0050] Such as Figure 7-10 As shown, a safety landing door for vertical lifting equipment includes a door frame 1 and a door leaf 2, one on the left and one on the left and right of the door leaf 2, and the door leaf 2 is movably arranged on the door frame 1, and the bottom of the door frame 1 is made of flat steel to facilitate the opening of the landing door After the personnel and material transport trolley pass through, an expansion board 5 is connected to the bottom of the door frame 1 through the movable connection device 4, and the expansion board 5 can cover the gap between the vertical lifting equipment and the landing door after being flipped down. The expansion board 5 is movably fixed on the bottom of the door frame 1 through the hinge or hinge, and the two sides of the top of the expansion board 5 are provided with door frame magnets 51 corresponding to the frames 101 on both sides of the door frame 1, and the frames on both sides of the door frame 1 101 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com