Semi-automatic chemical raw material barrel transfer vehicle structure

A technology for chemical raw materials and transfer vehicles, which is applied to motor vehicles, trolleys, trolley accessories, etc., can solve the problems of limited use process convenience, cumbersome operation of raw material barrels, and large volume of external equipment, and achieves stable lifting and convenient unloading. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

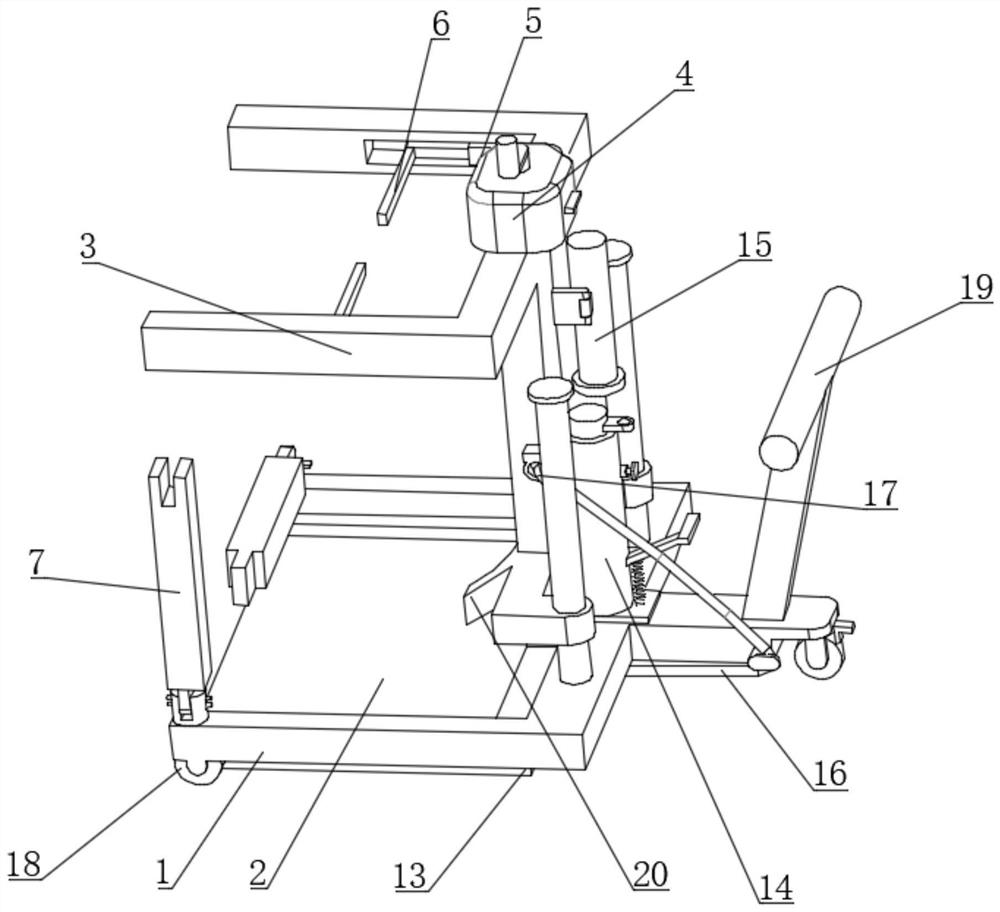

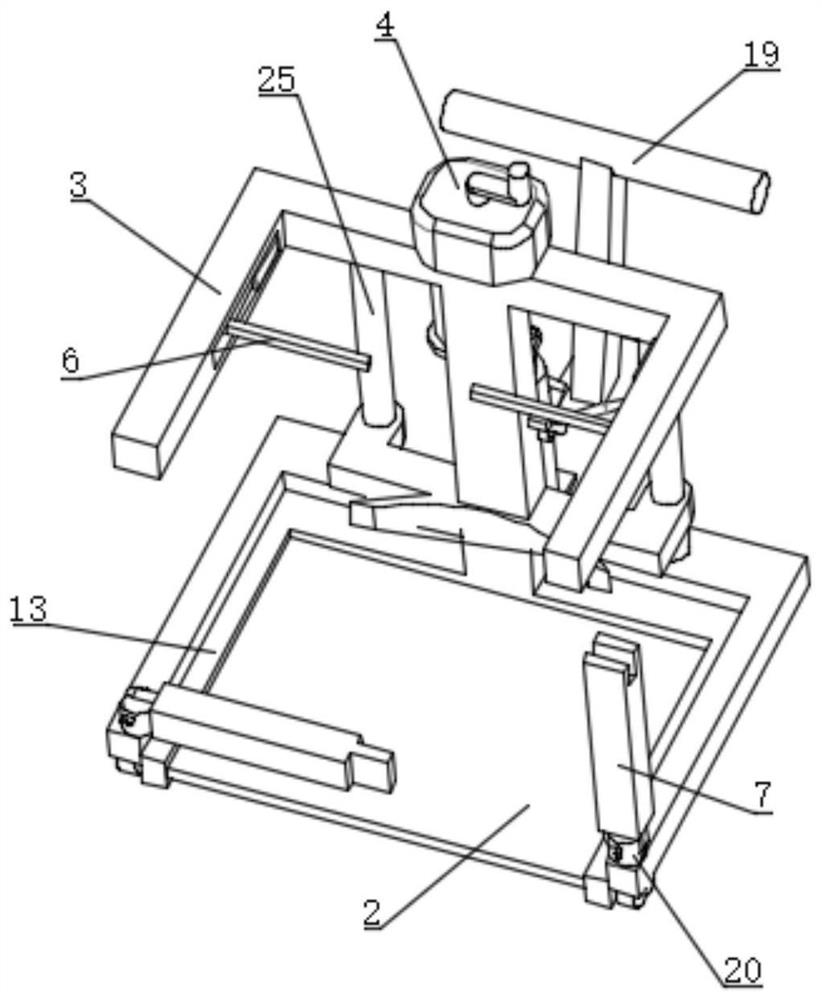

[0037] Embodiment 1. The crosspiece mechanism includes a hand pump 4, and the hand pump 4 communicates with two telescopic cylinders 5. The telescopic end of the telescopic cylinder 5 is connected with a gear lever 6, and the gear lever 6 is connected to the fork. The frame 3 is slidingly connected, and by manually shaking the hand pump 4, the two telescopic cylinders 5 can drive the gear rod 6 to move to the left, that is, to pry the upper end of the raw material barrel, so that a space appears below the raw material barrel,

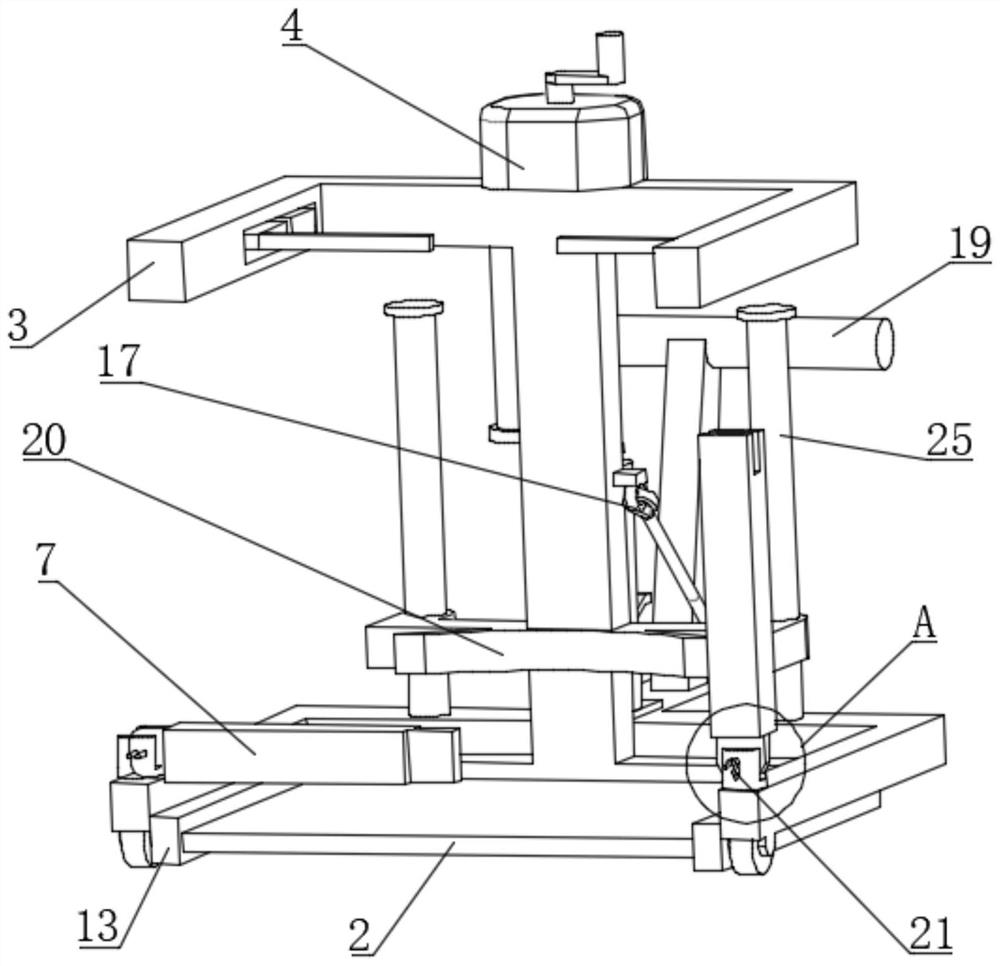

[0038] For this embodiment, in order to keep the raw material barrel stable when the gear rod 6 pushes the raw material barrel, the two sides of the upper end surface of the frame 1 are respectively provided with limit rods 7, such as figure 2 As shown, the frame 1 is respectively hinged to two limit rods 7 through a cylinder 21, and the ends of the two limit rods 7 are respectively presented as image 3 grooves and projections, so as to realize snap-f...

Embodiment 2

[0040] Embodiment 2, in order to reduce the volume and increase the adaptability of the whole structure to meet the application of larger raw material barrels, the crosspiece mechanism adopts the form of a steel wire rope 8, and specifically the upper end surface of the fork frame 3 is U-shaped, and The closed end of the U-shape is provided with a control cavity 9, and a rotating shaft 10 is rotatably connected to the control cavity 9. The two ends of the steel wire rope 8 bypass the open end of the U-shape and extend into the control cavity 9 and are fixed with the rotating shaft 10. connection, when used as Figure 12 In the shown state, the bottom plate 2 is on one side to prevent from obstructing the raw material bucket, and the steel wire rope 8 is in a state of tension and straightness. Then the fork frame 3 will be driven by pushing the push handle 19 close to the raw material bucket as Figure 12 As shown, in the process of approaching, because the steel wire rope 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com