Telescopic arm lifting hook

A telescopic boom and hook technology, applied in the field of telescopic boom hooks, can solve the problems of insufficient length, reduced permeability, limited adjustment distance, etc., and achieves the effects of large bearing capacity, low frictional resistance, and labor-saving expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

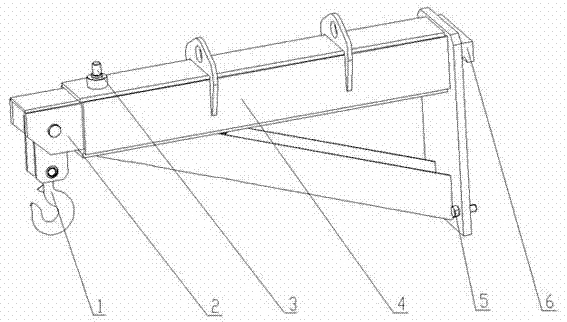

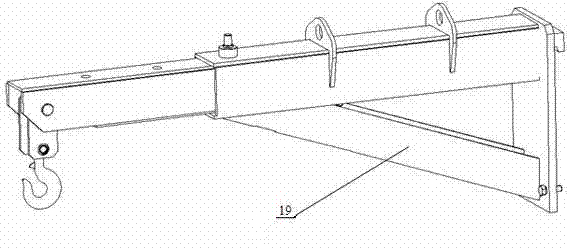

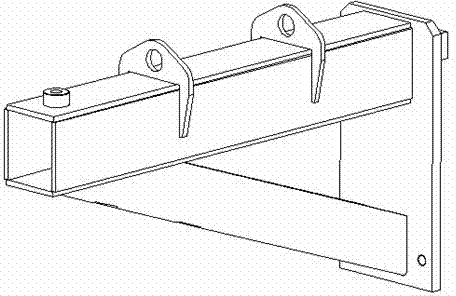

[0026] Embodiment 1 of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0027] Figure 1 to Figure 6 The telescopic arm hook shown includes a hook device 1, a second-stage boom 2, a fixed bolt 3, a first-stage boom 4, a fixed bolt 5, a hook 6, a rolling bearing group 7, a bolt 8, and a bearing seat 9 , composed of 10 elastic washers. The boom is a box-shaped structure welded by four plates, and the inside is hollow. A triangular bracing plate 19 is connected between the first-stage boom 4 and the vehicle fixing plate to form a tripod support structure. The second-stage boom 2 is a long box-shaped structure welded by four plates and can be placed on the first stage. Inside the stage boom. Four rolling bearings 7 are installed at the bottom of the bottom plate of the first stage boom 4, and are fixed with bolts 8 and elastic washers 10. Usually, the second-stage boom 2 is shrunk in the first-stage boom 4. When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com