Semi-electric self-lifting loading and unloading car

A loading and unloading truck, electric technology, applied in the field of storage stacking and handling equipment, can solve the problems of low work efficiency, waste of manpower, low efficiency, etc., and achieve the effect of reducing work intensity, improving work efficiency, and requiring less physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

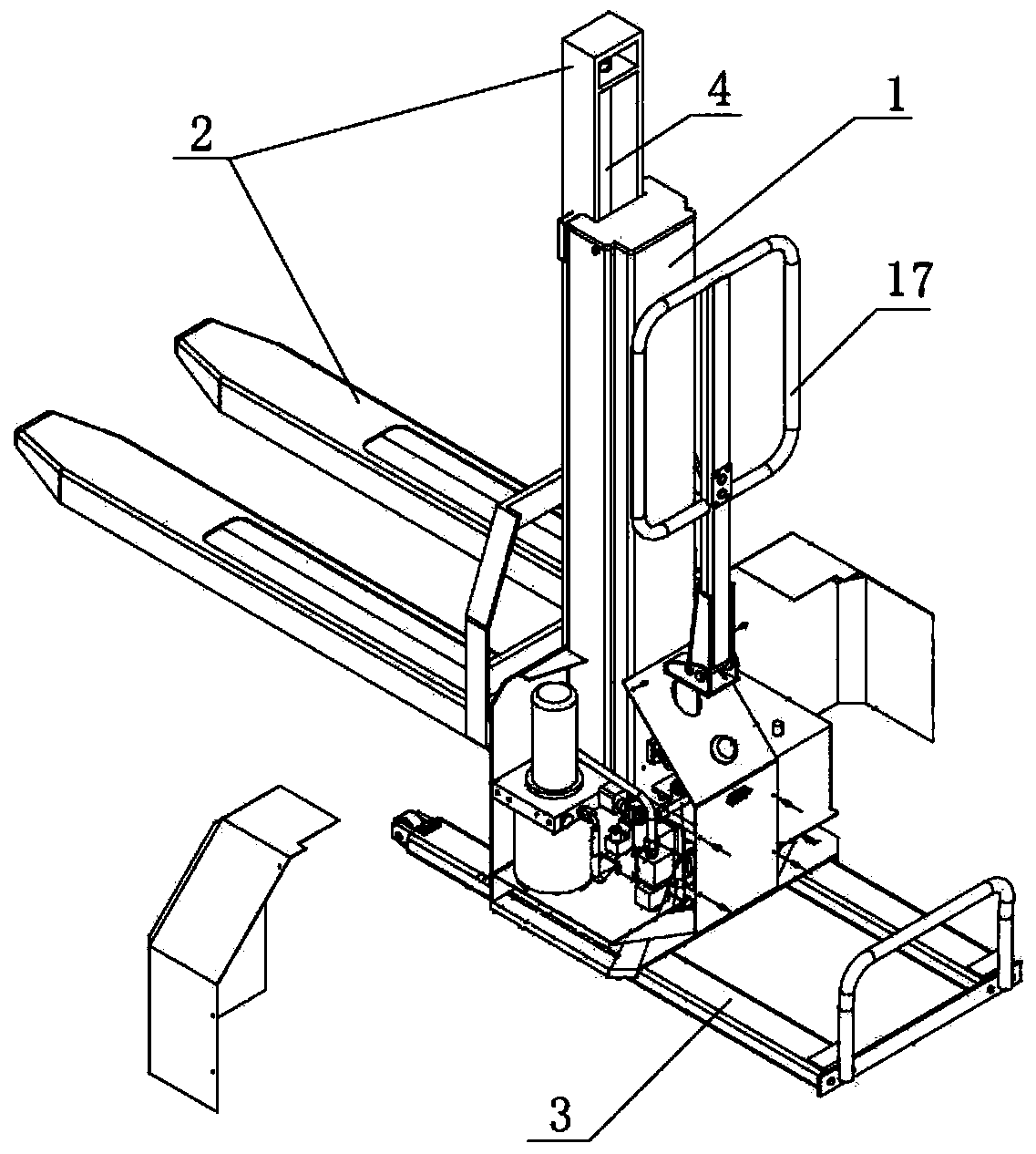

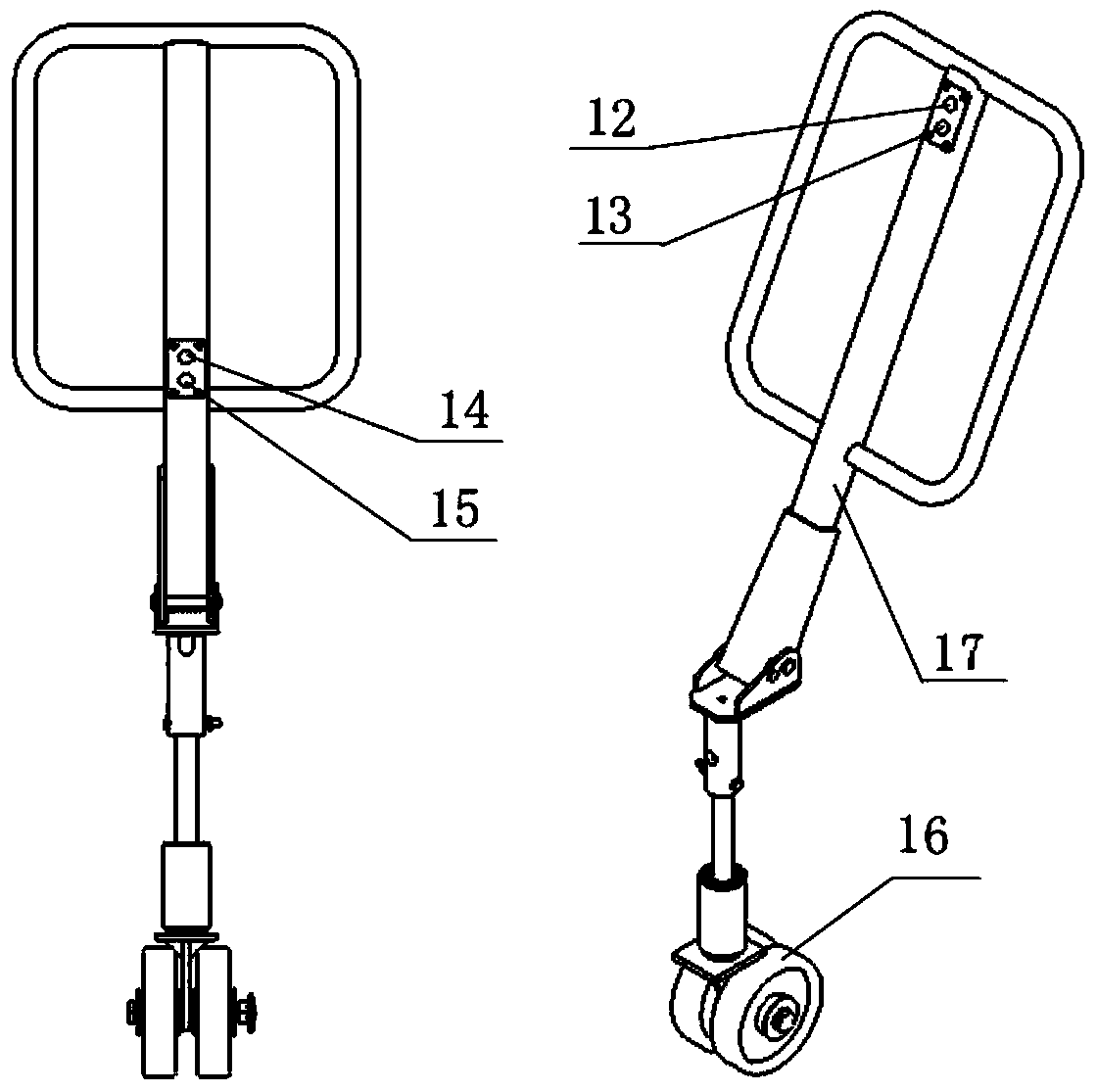

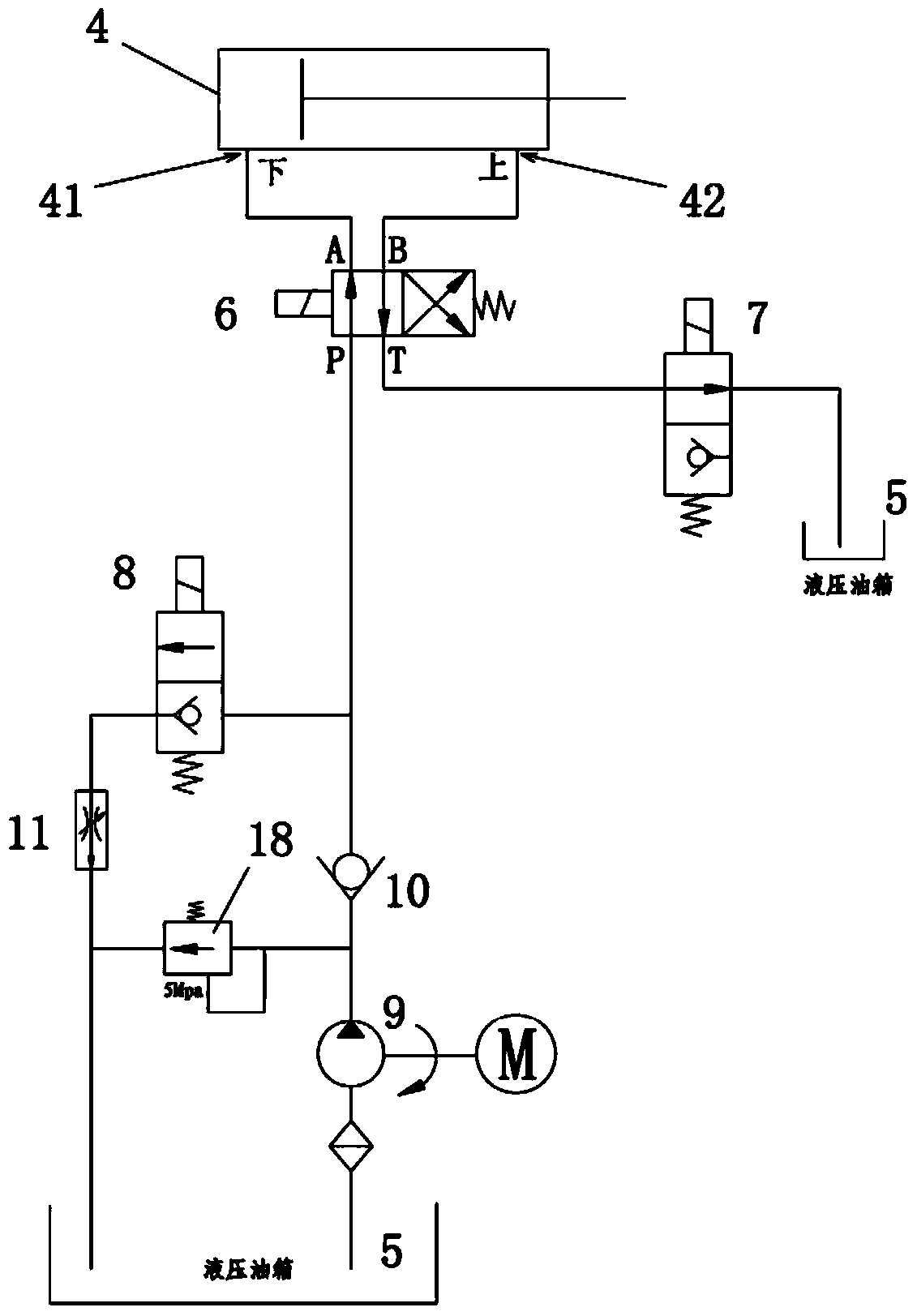

[0034] figure 1 A semi-electric self-elevating loading and unloading truck is shown, including a car body 1, a fork frame 2, a hydraulic system, and a telescopic caster frame 3; the fork frame 2 can be guided and moved up and down on the car body 1, The telescopic caster frame 3 is guided and moved forward and backward and is arranged at the lower end of the vehicle body 1; the hydraulic system includes a double-acting oil cylinder 4 and a hydraulic oil tank 5; the cylinder body of the double-acting oil cylinder 4 is connected with the vehicle The body 1 is fixedly connected, the piston rod of the double-acting oil cylinder 4 is in transmission connection with the fork frame 2, and the double-acting oil cylinder 4 is used to drive the lifting or lowering of the fork frame 2 or the car body 1; The hydraulic system is an electro-hydraulic system, and the hydraulic system is provided with a two-position four-way reversing solenoid valve 6, a first oil drain solenoid valve 7, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com