Crane type multi-directional horizontal-movement multifunctional hydraulic lifting construction method

A technology of hydraulic lifting and construction method, applied in the direction of lifting device, etc., can solve the problems of increasing the difficulty of hoisting, difficulty in reaching the boom of a crane, and high hoisting height, and achieve the effect of preventing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

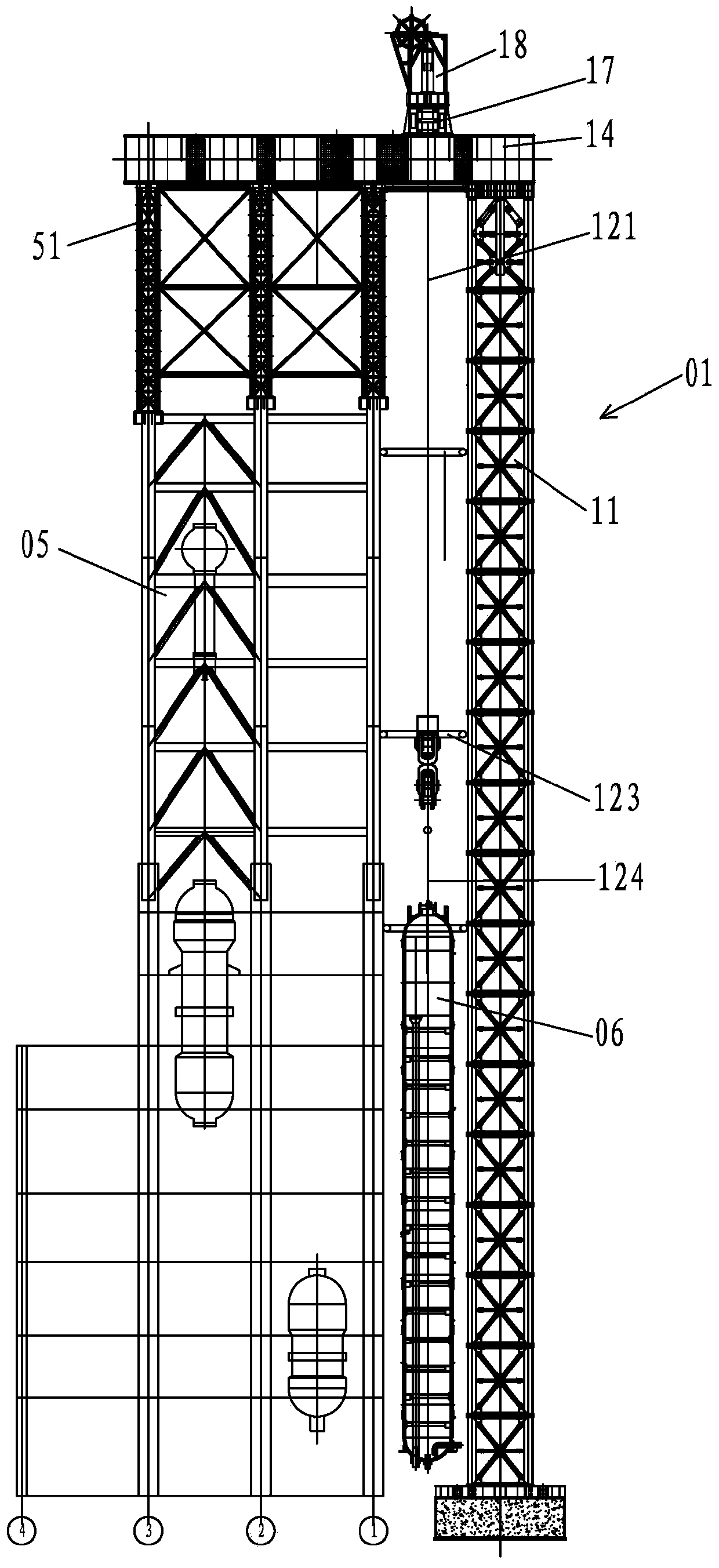

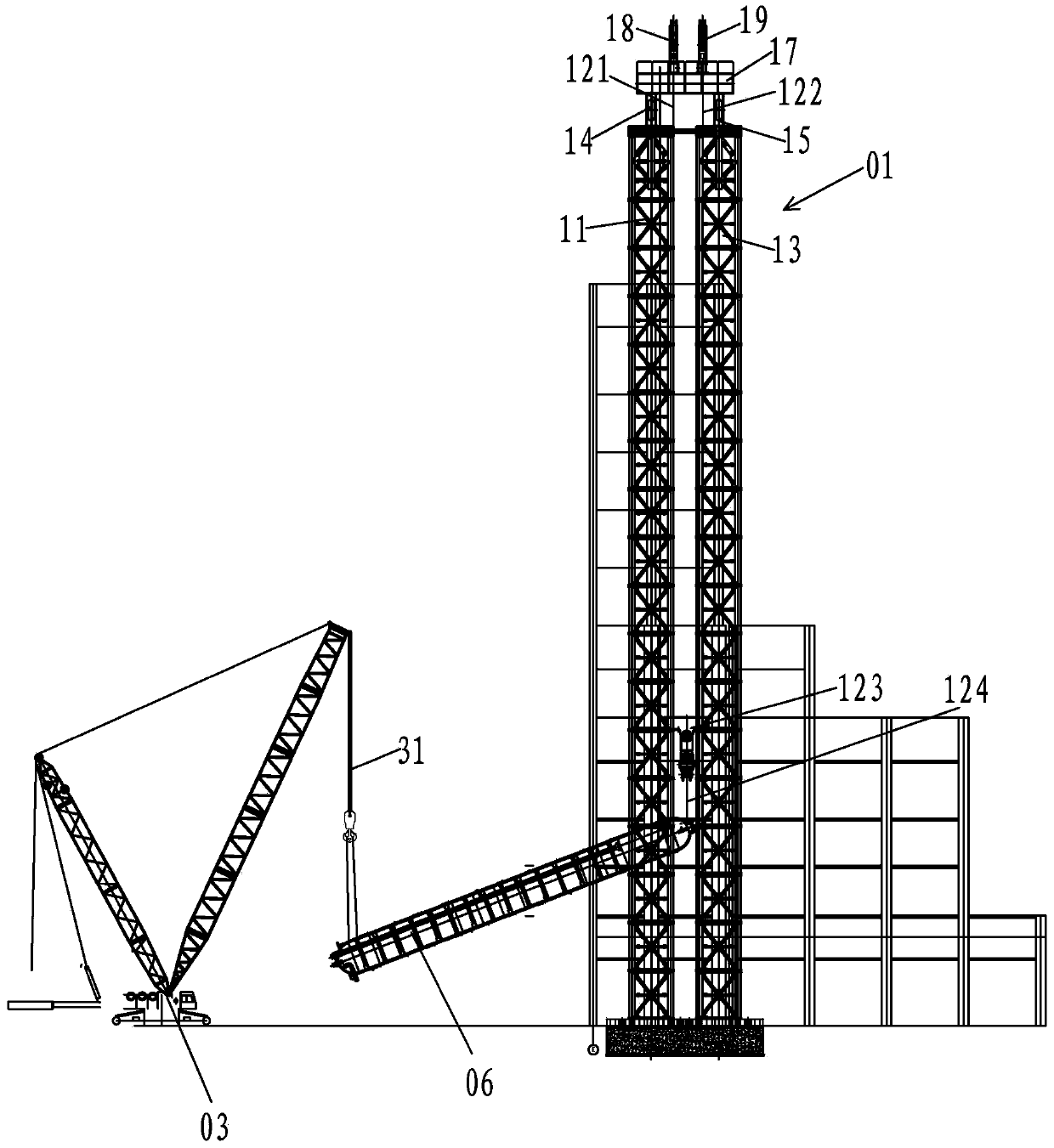

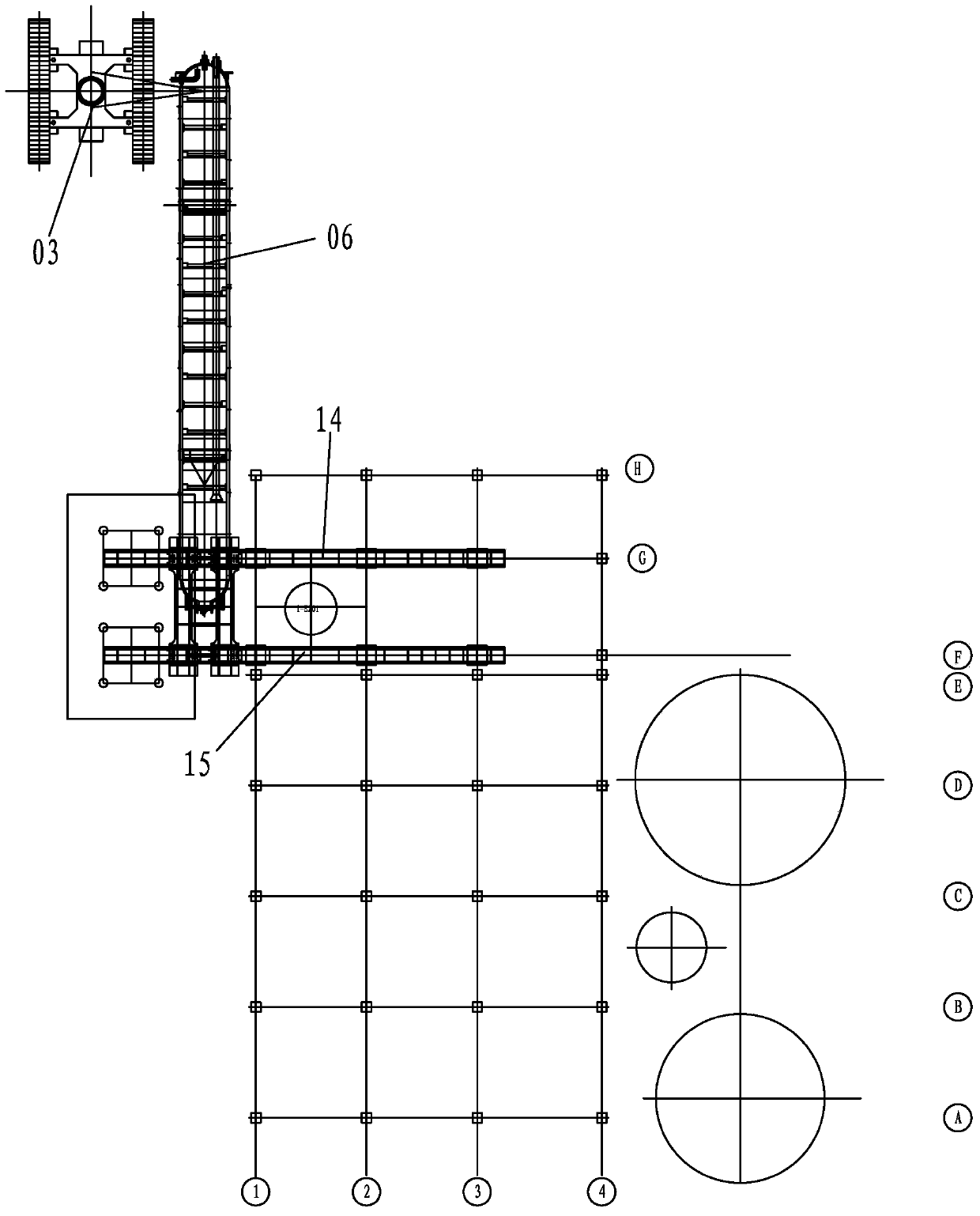

[0016] Such as figure 1 , 2 , 3, the gantry hydraulic lifting device 01 includes first and second gantry frames 11, 13, first and second load-bearing beams 14, 15, driving beam 17 and first and second hydraulic lifters 18, 19, The first and second hydraulic lifters 18, 19 are installed on the driving beam 17, the driving beam 17 is located above the first and second load-bearing beams 14, 15 and the two ends of the driving beam 17 are respectively supported on the first and second load-bearing beams 14 and 15, the driving beam 17 can slide on the first and second load-bearing beams 14 and 15, the first and second door frames 11 and 13 are vertically fixed on the ground, and the first and second load-bearing beams 14 and 15 are mutually Parallel, one end of the first load-bearing beam 14 is installed on the top of the first door frame 11, and the other end is installed on the temporary column 51 on the top of the frame building 05. One end of the second load-bearing beam 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com