Guide pipe frame-cylindrical structure combined offshore wind turbine foundation

A technology for cylindrical foundations and offshore wind turbines, applied in infrastructure engineering, construction, etc., can solve problems such as long construction periods, achieve low cost, convenient construction, and improve the ability to resist bending moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

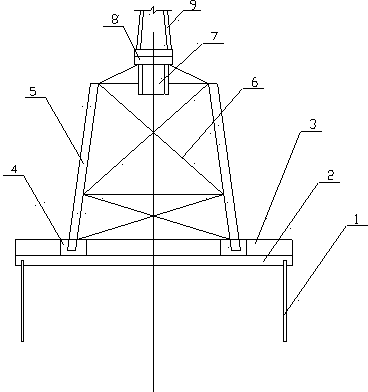

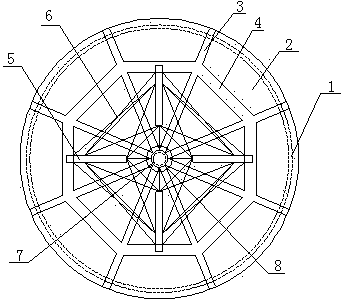

[0014] A jacket-cylindrical structure composite offshore wind turbine foundation, which consists of a cylindrical foundation part and a jacket part. The cylindrical foundation part includes a cylindrical steel wall 1, a concrete cover plate 2, a prestressed beam 3 and a connecting beam 4. The concrete cover plate 2 is set on the top of the cylindrical steel wall 1, the cylindrical steel wall 1 is embedded in the concrete cover plate 2, the prestressed beams 3 are set on the concrete cover plate 2, and four prestressed beams 3 are evenly arranged in the radial direction. The connecting beam 4 is arranged between two prestressed beams 3 and arranged evenly in the circumferential direction. The concrete cover plate 2, the prestressed beam 3 and the connecting beam 4 are poured and connected as a whole; the jacket part includes steel leg columns 5, steel supports Pipe 6, connecting cylinder 7 and flange 8, four steel leg columns 5 are arranged vertically or obliquely evenly, the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com