Semi-prefabricated semi-cast-in-place type frame structure of integrated building and construction method thereof

A frame structure, semi-prefabricated technology, applied in building construction, building material processing, construction, etc., can solve problems such as poor building integrity, and achieve the goal of improving overall safety, enhancing seismic performance, and improving overall stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

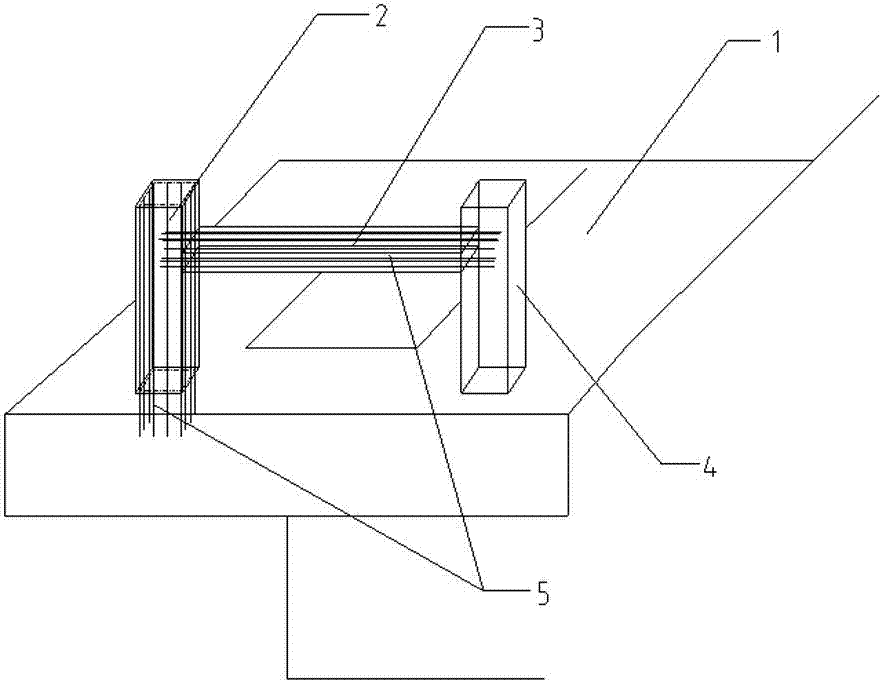

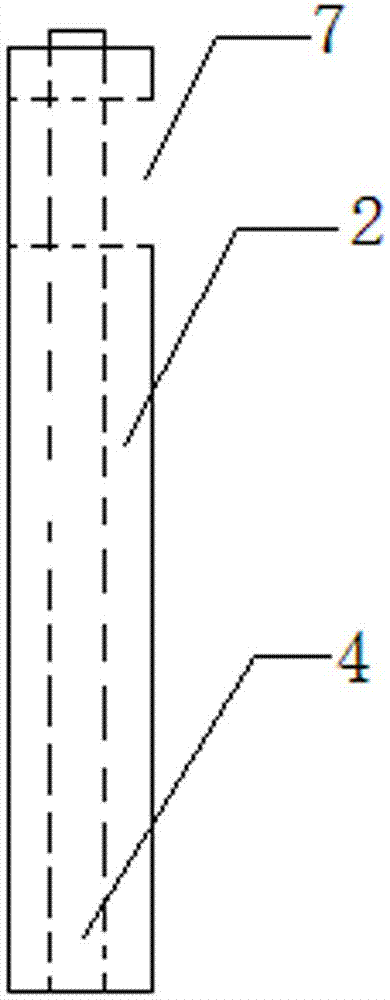

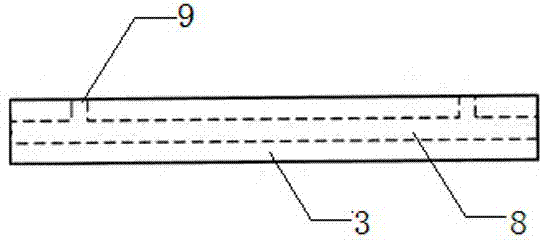

[0027] The semi-prefabricated and semi-cast-in-situ frame structure of the monolithic house provided in this embodiment is formed by combining semi-prefabricated frame columns, semi-prefabricated frame beams, fully prefabricated secondary beams and cast-in-situ foundation blocks to form a whole, and then Pouring concrete fills the reserved space in the semi-prefabricated frame columns and semi-prefabricated frame beams, and uses cast-in-place concrete and steel bars extending into the semi-prefabricated frame columns, semi-prefabricated frame beams and foundation blocks to connect the beams, columns, and foundations into a Integral, so as to improve the integrity and safety of structural members.

[0028] The structure of the semi-prefabricated and semi-cast-in-place frame structure of a monolithic house in this embodiment is as follows: figure 1 As shown, it includes a concrete poured foundation block 1 and at least one frame unit arranged on the foundation block, and each fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com